Two-channel optical fiber method and sensor for measuring turbidity

A measurement method and dual-channel technology, applied in the field of sensor measurement, can solve the problems that the measurement system does not realize temperature compensation, does not consider the influence of temperature on turbidity detection, and cannot realize remote data transmission, etc., so as to achieve low cost and improve use Effects of life and extended measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The invention will be further described below with reference to the accompanying drawings and specific embodiments.

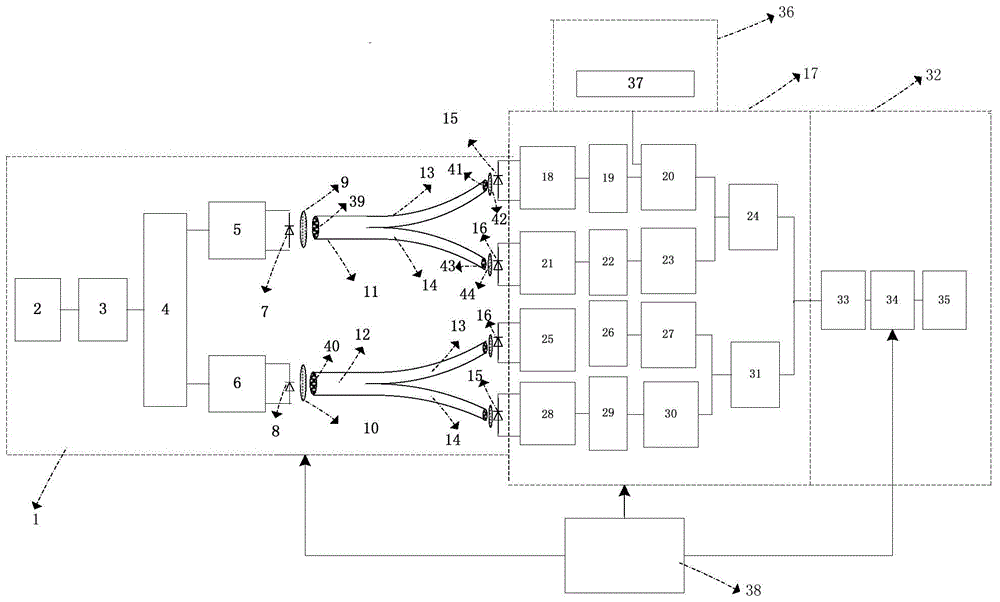

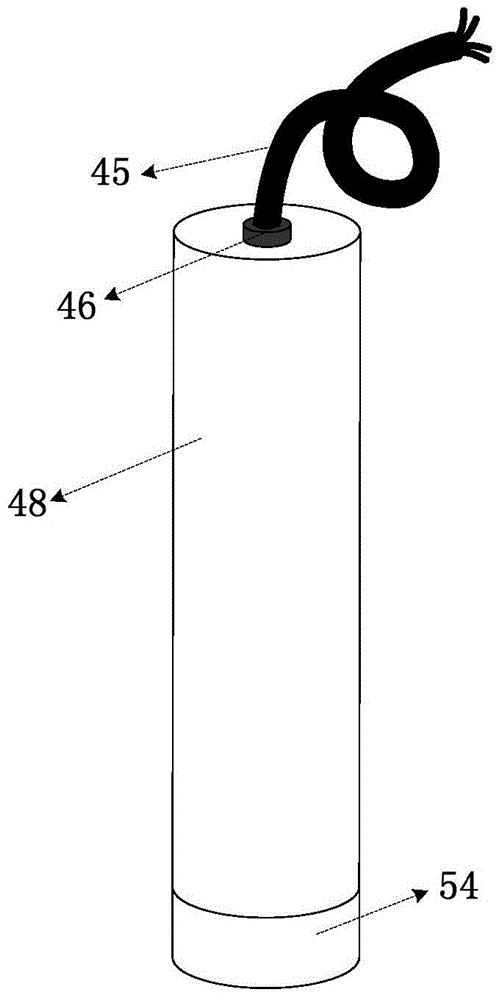

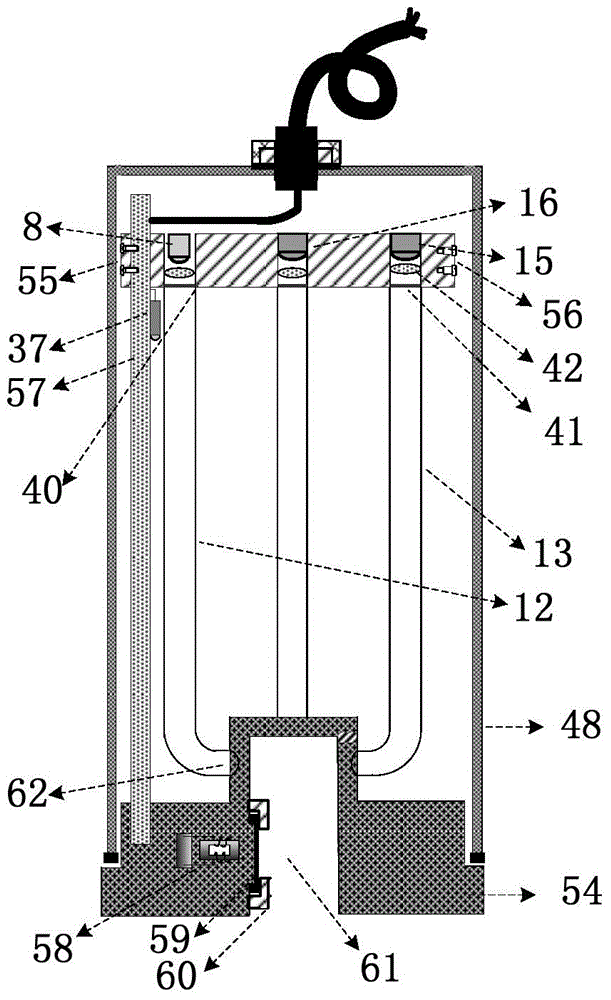

[0061] like figure 1 As shown, the fiber optic turbidity sensor of this embodiment is composed, in the figure:

[0062] Optical measurement module 1, including signal generator 2, two-way gate 4, LED drive circuit, LED1 light source 7 with a wavelength of 880nm, LED2 light source 8 with a wavelength of 660nm, two radiation fibers, four receiving fibers, four Sapphire lens and corresponding filter, four photodetectors and corresponding sapphire lens and band-pass filter; signal generator 2, rectifier 3, dual-channel gate 4, LED drive circuit periodically gate two wavelengths Different LED light sources, every 1S, the two LEDs turn on and off alternately;

[0063] The temperature measurement module 36 includes a temperature probe 37, and the probe adopts a Pt100 platinum resistance for collecting the temperature signal of the water body;

[0064] The si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com