Enzymatic method for preparing bone gelatin

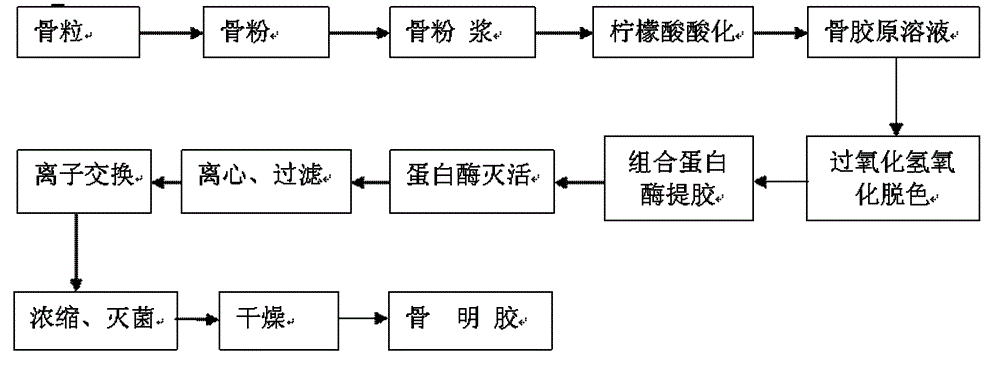

An enzymatic preparation and bone gelatin technology, applied in the direction of fermentation, can solve the problems of gelatin quality influence, enzyme inactivation, etc., and achieve the effect of shortening the period of degreasing and gelatinization, high degreasing rate, and shortening the production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present embodiment adopts the pork bone of 1 kg, prepares bone gelatin by the method of the present invention, comprises the following steps;

[0038] (1) Degreasing: Put the bone particles into a pulverizer for crushing, the particle size is ≤2 mm, then add acetone to the bone meal for degreasing, the volume of acetone is 5 L, soak at room temperature for 4 h;

[0039] (2) Add water to make slurry: add 2 kg of deionized water to the defatted bone meal, stir to make a bone meal slurry;

[0040] (3) Homogenizer pulverization: add the bone meal slurry into the homogenizer to make it finer, with a particle size of 10 μm;

[0041](4) Acidification with citric acid: add citric acid with a concentration of 0.05mol / L to the defatted bone powder, the weight ratio of citric acid to bone powder is 0.1:1, and acidify at room temperature for 4 hours to obtain a collagen solution;

[0042] (5) Hydrogen peroxide decolorization: Add hydrogen peroxide with a concentration of 10% t...

Embodiment 2

[0050] The present embodiment adopts the bovine bone of 1 kg, prepares bone gelatin by the method of the present invention, comprises the following steps;

[0051] (1) Degreasing: Put the bone particles into a pulverizer for crushing, then add 8 L of acetone to the bone powder for degreasing, and soak for 8 hours at room temperature;

[0052] (2) Add water to make slurry: add deionized water to the degreased bone meal, the weight of deionized water is 3 times that of the bone meal, stir to make a bone meal slurry;

[0053] (3) Homogenizer pulverization: add the bone meal slurry into the homogenizer to make it finer, with a particle size of 20 μm;

[0054] (4) Acidification with citric acid: add citric acid with a concentration of 0.1mol / L to the defatted bone powder for acidification, and the weight ratio of citric acid to bone powder is 0.5:1 to obtain a collagen solution;

[0055] (5) Hydrogen peroxide decolorization: Add hydrogen peroxide with a concentration of 12% to the...

Embodiment 3

[0060] The present embodiment adopts the sheep bone of 1 kg, prepares bone gelatin by the method of the present invention, comprises the following steps;

[0061] (1) Degreasing: Put the bone particles into a pulverizer for crushing, then add 10L acetone to the bone meal for degreasing, and soak at room temperature for 12 hours;

[0062] (2) Add water to make slurry: add deionized water to the degreased bone meal, the weight of the deionized water is 4 times that of the bone meal, stir to make a bone meal slurry;

[0063] (3) Acidification with citric acid: add citric acid with a concentration of 0.3 mol / L to the defatted bone powder for acidification, and the weight ratio of citric acid to bone powder is 0.8:1 to obtain a collagen solution;

[0064] (4) Homogenizer pulverization: add the bone meal slurry into the homogenizer to make it finer, with a particle size of 30 μm;

[0065] (5) Hydrogen peroxide decolorization: Add hydrogen peroxide with a concentration of 15% to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com