Environment-friendly water-based paint and preparation method thereof

A water-based paint and environmentally friendly technology, applied in the field of coatings, can solve the problems of complex preparation process of nano-mixtures and inability to release negative ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Correspondingly, the present invention also provides a preparation method of an environmentally friendly water-based paint, comprising the following steps: step a) mixing 0.5 to 5 parts by weight of a defoamer, 1 to 20 parts by weight of a thickener, 1 to 10 parts by weight of a dispersant and Put 0-200 parts by weight of water into the mixer, add 50-150 parts by weight of composite anion powder and 40-100 parts by weight of anion additive after the dispersion is complete, and stir evenly. The speed of the mixer is 600-2500 rpm. It is composed of crystal salt, nano-silica, nano-phosphate titanium dioxide and nano-zinc dioxide; step b) reduce the speed of the mixer to 400-800 rpm, mix 700-900 parts by weight of water-based resin dispersion, 10-100 parts by weight The film-forming aid, 0.5-5 parts by weight of the defoamer and 0.1-1 part by weight of the pH regulator are put into the mixer, and stirred for 30-50 minutes to obtain an environmentally friendly water-based pai...

Embodiment 1

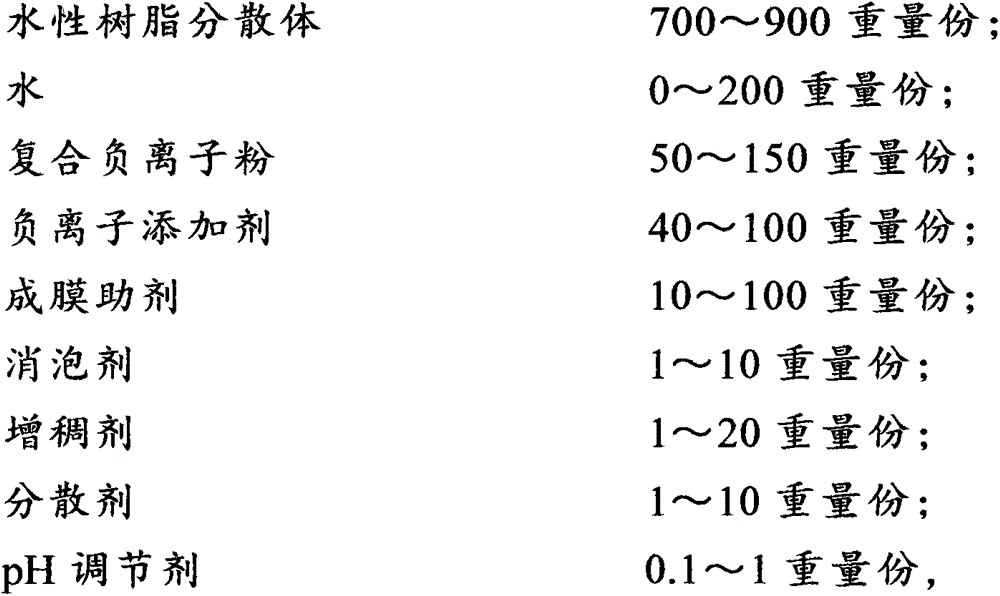

[0062] The described water-based paint capable of releasing negative ions comprises the following components, and the parts by weight of each component are:

[0063]

[0064] Wherein, the parts by weight of each component in the composite anion powder are respectively:

[0065]

[0066] Wherein, the parts by weight of each component in the negative ion additive are respectively:

[0067]

[0068] The preparation process steps of the water-based paint capable of releasing negative ions are as follows:

[0069] 1) Prepare raw materials according to the set weight percentage, put water, thickener, dispersant and 50% defoamer into the high-speed mixer, and after the dispersion is complete, slowly add composite anion powder and anion additive, Until the desired fineness is achieved, the speed of the high-speed stirrer is 1600 revolutions per minute.

[0070] 2), reduce the rotating speed of the agitator to 600 revolutions per minute. According to the set weight percenta...

Embodiment 2

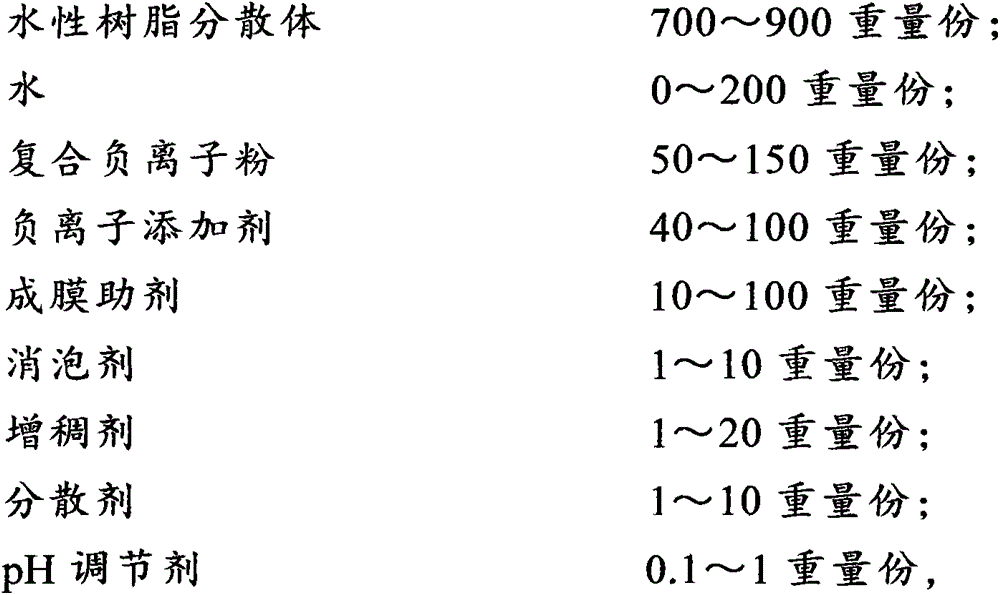

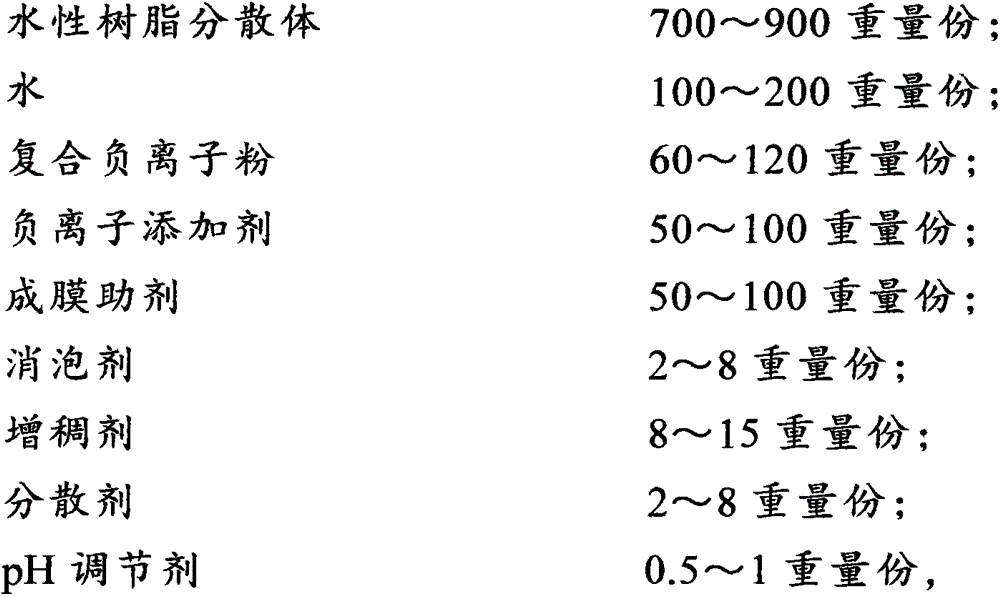

[0072] The described water-based paint capable of releasing negative ions comprises the following components, and the parts by weight of each component are:

[0073]

[0074] Wherein, the parts by weight of each component in the composite anion powder are respectively:

[0075]

[0076] Wherein, the parts by weight of each component in the negative ion additive are respectively:

[0077]

[0078] The preparation process steps of the water-based paint capable of releasing negative ions are as follows:

[0079] 1) Prepare raw materials according to the set weight percentage, put water, thickener, dispersant and 50% defoamer into the high-speed mixer, and after the dispersion is complete, slowly add composite anion powder and anion additive, until the desired fineness is achieved. The speed of the high-speed stirrer was 1500 revolutions per minute.

[0080] 2), reduce the rotating speed of the agitator to 600 revolutions per minute. According to the set weight percen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com