Zero-valent iron reduction-Fenton oxidation integrated reaction device and method for treating nitroaromatic compound wastewater by using zero-valent iron reduction-Fenton oxidation integrated reaction device

A reaction device, Fenton oxidation technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. To solve the problems of engineering application of coupling technology and large secondary pollution, it can achieve the effect of simplifying the process of wastewater treatment, reducing treatment costs and reducing the production of iron sludge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

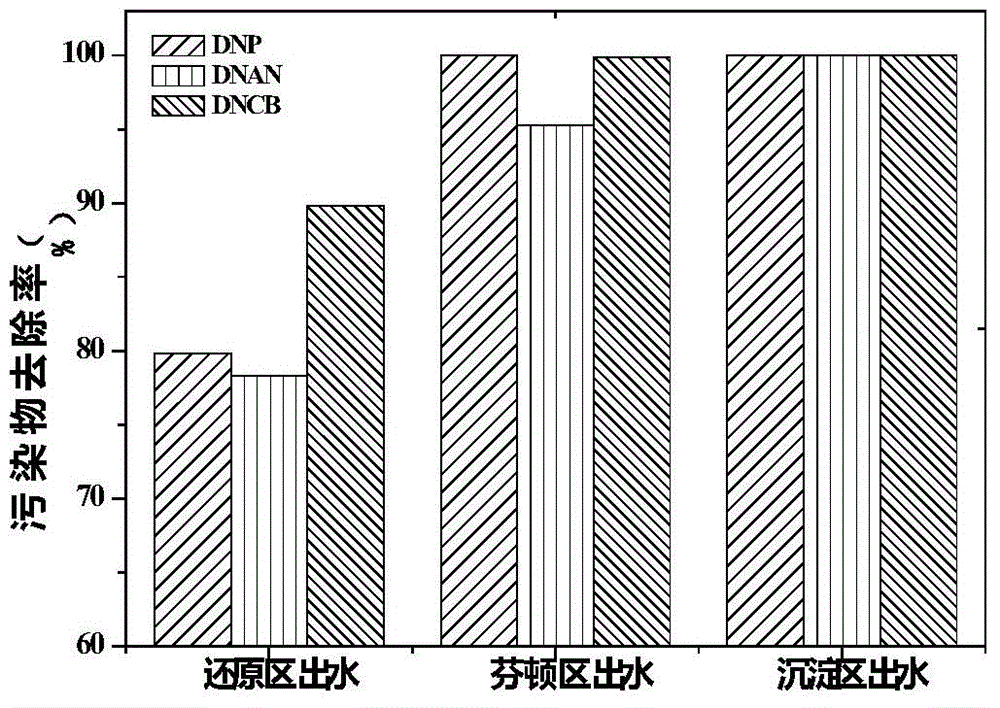

[0028] Example 1: Treatment of 2,4-Dinitroanisole Washing Wastewater by Zero-Valent Iron Reduction-Fenton Oxidation Coupling System

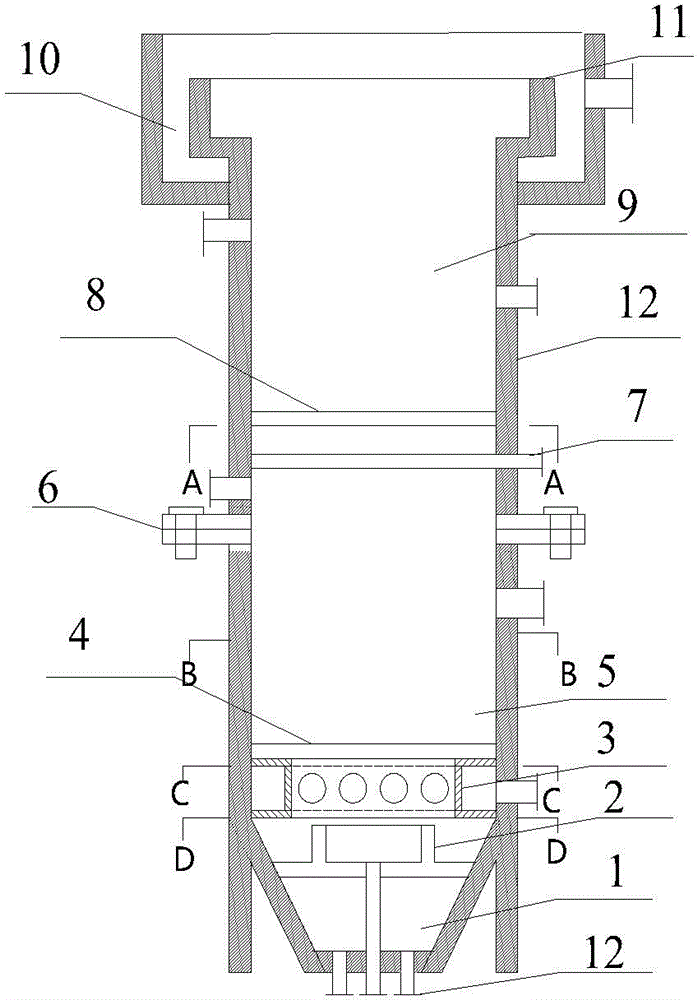

[0029] The zero-valent iron reduction-Fenton oxidation integrated device adopted in the present invention is as figure 1 As shown, the reaction device includes a reactor body in a hollow cylindrical structure. The reactor body is made of plexiglass. The inside of the reactor body is divided into iron slime collection area 1, zero-valent iron reduction area 5, and zero-valent iron reduction area from bottom to top. Valence iron Fenton oxidation zone 9 and precipitation zone 10 four reactions, and zero-valent iron reduction zone 5 and zero-valent iron Fenton oxidation zone 9 are covered with iron shavings; iron mud collection zone 1 includes sludge discharge valve 12 and exposure Gas device 2; the zero-valent iron reduction zone 5 is composed of the first partition 4 and the water distributor 3, the first partition 4 is used to carry the iron shav...

Embodiment 2

[0037] Embodiment 2: the influence of hydrogen peroxide concentration on the removal effect of nitroaromatic compounds

[0038] Set the reaction conditions of HRT=24h, zero-valent iron Fenton oxidation zone pH is 6, adjust the pumping amount of hydrogen peroxide in dosing device 7, and explore the effect of different concentration of hydrogen peroxide on UV 254 The change of the value and the influence of the change of TOC removal rate.

[0039] Depend on Image 6 It can be seen that the UV of wastewater after treatment in each reaction zone 254 The value is gradually reduced, especially when the concentration of hydrogen peroxide is 10mL / L, the UV 254 The change in the value is most obvious, and the UV of the final wastewater 254 The value is 0.14, which means that the removal effect of the target pollutants and their reduction products is the best under the condition of the concentration of hydrogen peroxide. The results showed that when the concentration of hydrogen per...

Embodiment 3

[0041] Example 3: Influence of the pH value of the zero-valent iron Fenton oxidation zone on the removal effect of nitroaromatic compounds

[0042] Under the reaction conditions of HRT=24h and hydrogen peroxide concentration of 10mL / L, the pH value of the zero-valent iron Fenton oxidation zone was controlled by adjusting the pumping amount of the sulfuric acid solution in the dosing device 7, and the zero-valent iron Fenton oxidation zone was explored. The pH value of the oxidation zone is related to the UV in the zone 254 Value changes and the impact of TOC removal rate changes.

[0043] Depend on Figure 8 Visible, UV of water 254 The value is 0.84, after the treatment of the zero-valent iron Fenton oxidation zone, the UV 254 value dropped significantly. When the pH value of the zero-valent iron Fenton oxidation zone is 3, the UV of the effluent 254 The value is the lowest, which is 0.10. As the pH value of the Fenton oxidation zone increases, the UV of the effluent 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com