Molding process for straight bevel gear

A straight-toothed bevel gear and forming process technology, which is applied in the field of straight-toothed bevel gear processing technology, can solve the problems of scale, low gear precision, and poor surface quality, and achieve shortened production cycle, high precision, and small equipment tonnage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

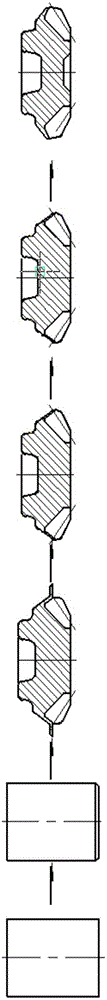

Image

Examples

Embodiment 1

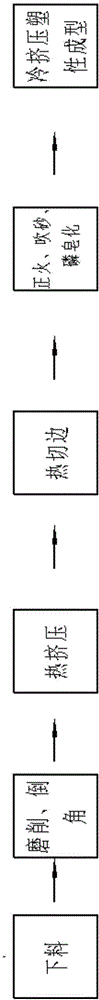

[0025] The forming process of straight bevel gear, the raw material is 20CrMnTiH round steel, according to the following steps:

[0026] 1). Tooth mold modeling: including rough forging tooth mold and finishing tooth mold modeling, the indexing circular chord tooth thickness of the rough forging tooth mold is slightly smaller than the finishing tooth mold, and the overall tooth height of the rough forging tooth mold is greater than the fine The overall height of teeth of the whole tooth mold; 0.992 single tooth shape volume of rough forging tooth mold = single tooth shape volume of finishing tooth mold × 1.008.

[0027] The tooth shape of the rough forging tooth die obtained in this step is thinner and taller than the tooth shape of the finishing tooth die. The reason is: during fine calibration, the tooth top of the rough forging will first contact the tooth top of the finishing tooth mold. , the principle is similar to pier rough extrusion. Because during the subsequent no...

Embodiment 2

[0037] The forming process of straight bevel gear, the raw material is 20CrMnTiH round steel, according to the following steps:

[0038] 1). Tooth mold modeling: including rough forging tooth mold and finishing tooth mold modeling, the indexing circular chord tooth thickness of the rough forging tooth mold is slightly smaller than the finishing tooth mold, and the overall tooth height of the rough forging tooth mold is greater than the fine Overall tooth height of the whole tooth mold; 0.992 single tooth shape volume of rough forging tooth mold = single tooth shape volume of finishing tooth mold × 1.008;

[0039] 2). Warm forging plastic forming: a. Saw material: CNC sawing machine intercepts metal bar to obtain solid cylindrical material; b. Billet making: use centerless grinder to remove black skin on the surface of solid cylinder, and use double-sided chamfering machine to chamfer; c. Heating: Put the bar into an intermediate frequency heating furnace and heat it to 820-830...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com