Treating method for vulcanized hydrogenation catalyst

A technology of hydrogenation catalyst and treatment method, which is applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of loss of active components and decrease of catalyst activity, saving start-up time and improving processing time. Hydrogen activity, easy storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

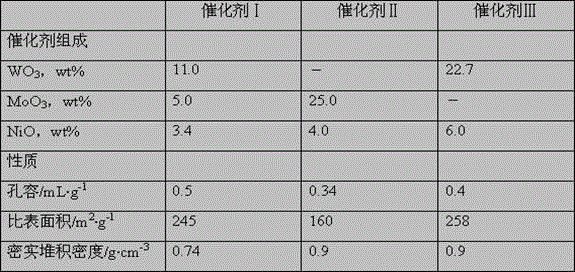

[0028] The preparation of embodiment 1 catalyst A

[0029] Get 100g oxidation state catalyst I, pass into the mixed gas of hydrogen and hydrogen sulfide, H 2 :H 2 S=4:1, heat up to 300°C for 6 hours of vulcanization, cool down and take out the catalyst to obtain a vulcanized catalyst. Spray and immerse with an aqueous solution of nickel citrate (2.5g / 100ml in terms of nickel), so that the introduced nickel citrate (in terms of nickel oxide) accounts for 0.5% of the weight of the sulfurized catalyst, and then treat it at 150°C under nitrogen protection After 6 hours, catalyst A was obtained.

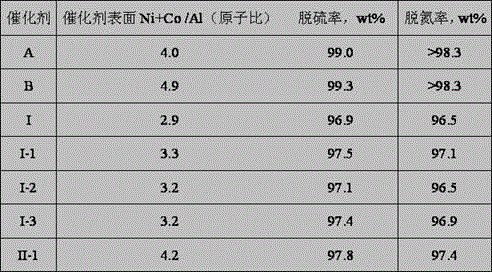

[0030] Put catalyst A into the reactor, directly raise the temperature to 350°C, introduce raw material oil, and start the hydrogenation reaction at constant temperature for 6 hours, and take samples for analysis after 24 hours of reaction. Reaction conditions: reaction temperature 350°C, reaction pressure 3.4MPa, hydrogen-to-oil ratio 360, volume space velocity 2.0, see Table 2 for th...

Embodiment 2

[0031] The preparation of embodiment 2 catalyst B

[0032] Take 100g of oxidation state catalyst II, pass through hydrogen, raise the temperature to 120°C and start to feed vulcanized oil, which contains CS 2 5% (v%), after constant temperature for 1 hour, continue to heat up to 230°C for 3 hours, then heat up to 300°C for 3 hours, cool down and take out the catalyst to obtain a vulcanized catalyst. Spray immersion with an aqueous solution of cobalt citrate (concentration calculated as cobalt: 4.5g / 100ml), so that the introduced cobalt citrate (calculated as cobalt oxide) accounts for 1% of the weight of the sulfurized catalyst, and then treat it under air at 120°C for 12 hours, the catalyst B was obtained.

[0033]Catalyst B was loaded into the reactor, and the start-up process and reaction conditions were the same as in Example 1, and its hydrodesulfurization activity was shown in Table 2.

Embodiment 3

[0034] The preparation of embodiment 3 catalyst C

[0035] Take 100g of catalyst III in oxidation state, feed hydrogen, heat up to 150°C and start to feed vulcanized oil, the vulcanized oil contains 5% (v%) of dimethyl disulfide, keep the temperature for 1 hour, then continue to heat up to 230°C for 3 hours. , after which the temperature was raised to 300°C for 3 hours to be vulcanized, and the temperature was lowered to take out the catalyst to obtain a sulfurized catalyst. Spray immersion with an aqueous solution of nickel citrate (5.0g / 100ml in terms of nickel), so that the introduced nickel citrate (in terms of nickel oxide) accounts for 1.5% of the weight of the sulfurized catalyst, and then treat it in air at 120°C After 12 hours, catalyst C was obtained.

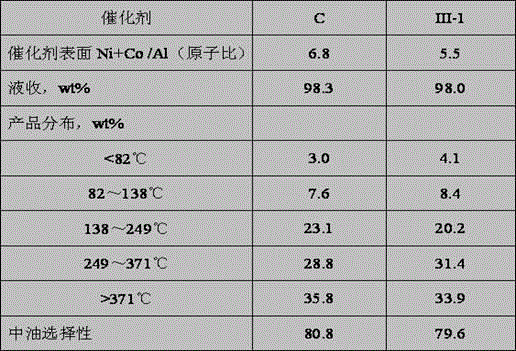

[0036] Put catalyst C into the reactor, directly raise the temperature to 370°C, introduce raw material oil, and start the hydrogenation reaction at constant temperature for 6 hours, and take samples for analysis aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com