Antibiotic seed treatment agent composition

A technology of seed treatment and antibiotics, applied in the field of pesticides, can solve the problems of slow research and development, poor water resistance of film coating materials, etc., and achieve the effects of improving the seedling rate, prolonging the lasting effect, and improving the germination rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

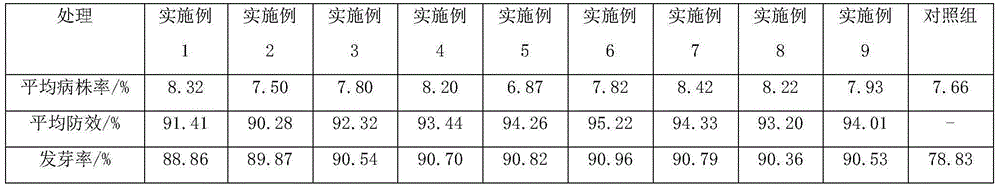

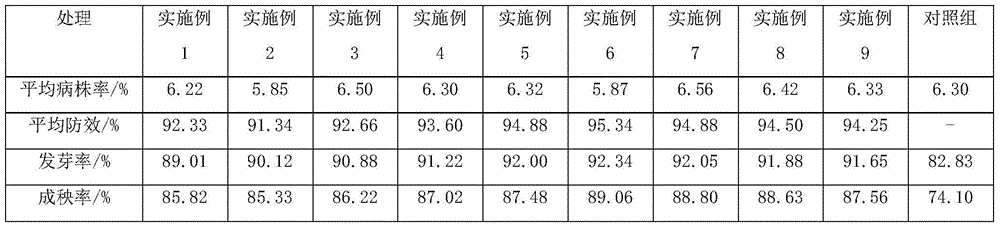

Examples

Embodiment 1

[0023] Take organic bentonite 20% and sodium lignosulfonate 5%, add nitenpyram 1% and 6% kasugamycin, mix well under mechanical stirring, then add film-forming agent ethyl cellulose 10%, emulsifier fat Alcohol polyoxyethylene ether 3%, antifreeze agent ethylene glycol 1%, defoamer silicone oil 0.3%, preservative sodium benzoate 0.05%, colorant acid red 0.5%, viscosity regulator borax 0.1%; deionized water added to 100%, stir evenly to get the seed coating agent. The seeds to be coated are added to the seed coating agent at a ratio of 1:40 (mass ratio) between the seed coating agent and the seeds, stirred evenly, and then dried at 45°C, all of which are in weight percentage.

Embodiment 2

[0025] Take 20% organic bentonite and 5% sodium lignosulfonate, add 8% nitenpyram and 1% saturated solution of agricultural streptomycin dissolved in dichloromethane, mix well under mechanical stirring, then add soluble in water Film-forming agent ethyl cellulose 7%, emulsifier fatty alcohol polyoxyethylene ether 3%, antifreeze agent ethylene glycol 1%, defoamer silicone oil 0.3%, preservative sodium benzoate 0.05%, colorant acid red 0.5% %, viscosity modifier 0.1% borax, and finally replenished to 100% with deionized water, and stirred evenly to obtain the seed coating agent. The seeds to be coated are added to the seed coating agent at a ratio of 1:40 (mass ratio) between the seed coating agent and the seeds, stirred evenly, and then dried at 45°C, all of which are in weight percentage.

Embodiment 3

[0027] Take 20% of organic bentonite and 5% of sodium lignosulfonate, add 5% of nitenpyram and 3% of antimycotic 120, mix well under mechanical stirring, then add 1% of film-forming agent polyvinyl acetate and ethyl Cellulose 4%, emulsifier fatty alcohol polyoxyethylene ether 3%, heat to remove dichloromethane after stirring and mixing, finally add organic bentonite 20%, sodium lignosulfonate 5%, refrigerant ethylene glycol 1%, disinfectant Foaming agent silicone oil 0.3%, preservative sodium benzoate 0.05%, colorant acid red 0.5%, stir evenly to obtain seed coating agent. The seeds to be coated are added to the seed coating agent at a ratio of 1:40 (mass ratio) between the seed coating agent and the seeds, stirred evenly, and then dried at 45°C, all of which are in weight percentage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com