Circuit board and circuit board manufacturing method

A circuit board production and circuit board technology, which is applied in the direction of printed circuit manufacturing, printed circuit, printed circuit, etc., can solve problems such as difficulty in meeting light and thin, poor return effect, and poor conductive effect, so as to prevent electromagnetic interference and reduce The effect of production cost and shortened process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The circuit board provided by the technical solution and its manufacturing method will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0020] The circuit board manufacturing method provided by the embodiment of the technical solution includes the following steps:

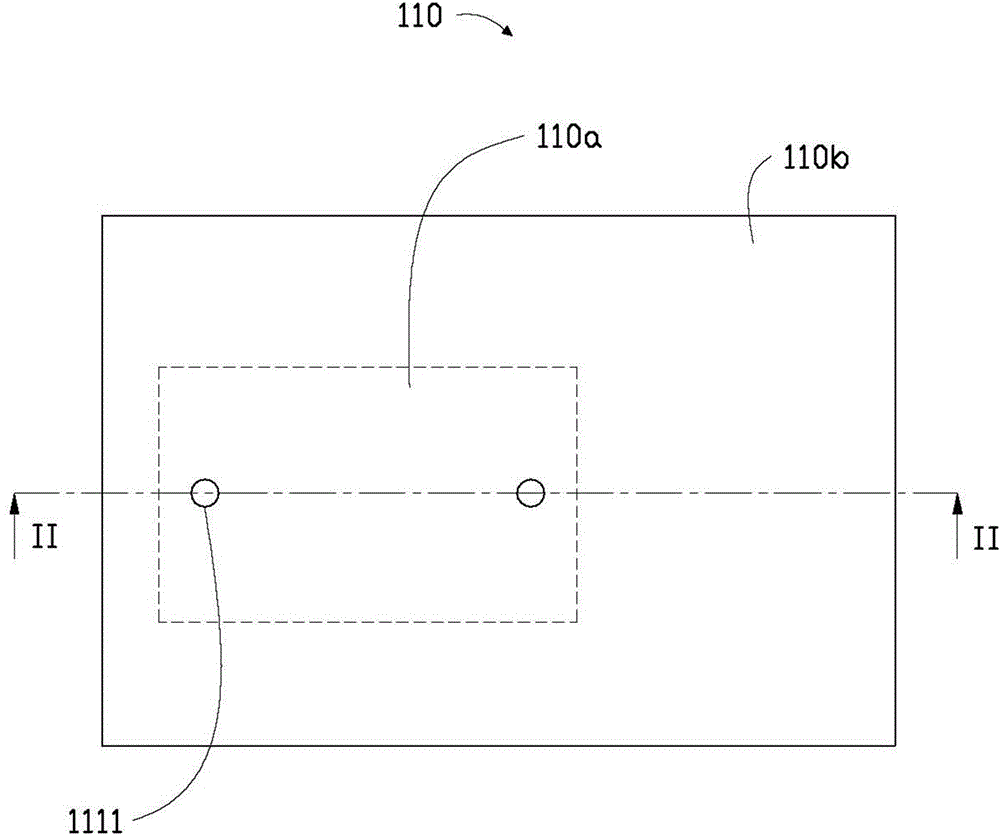

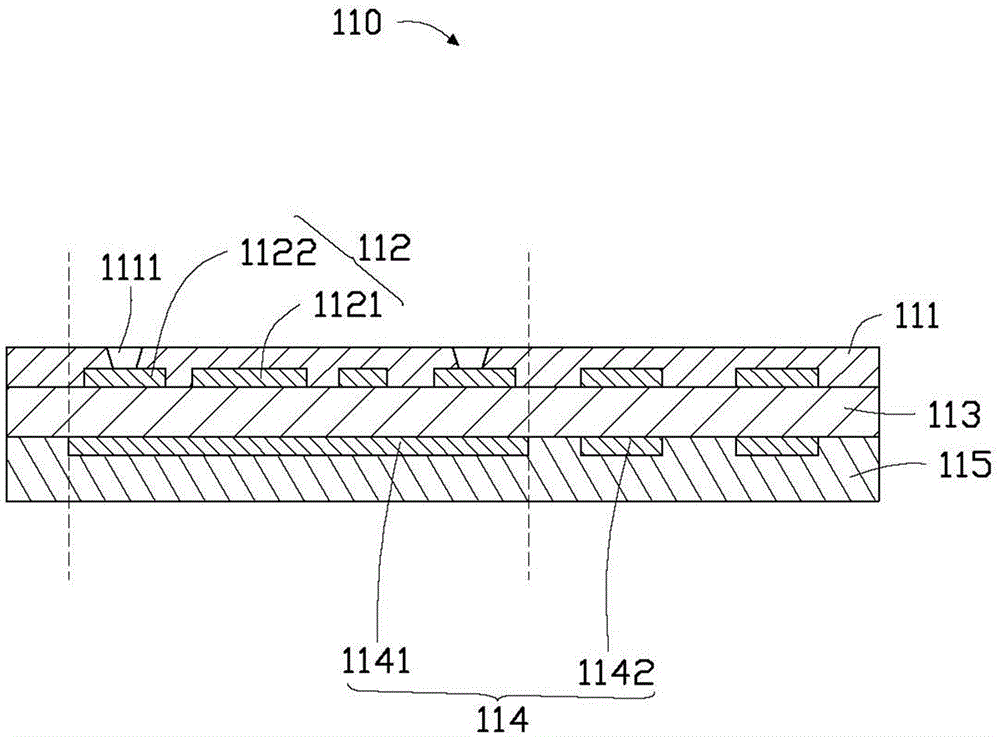

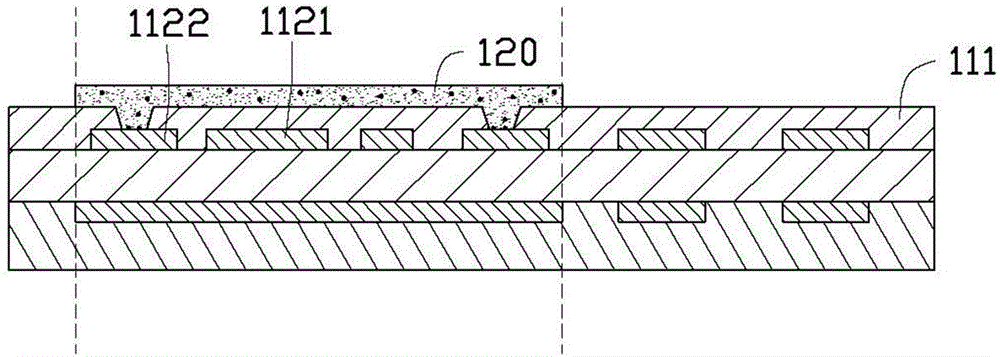

[0021] For a first step, see figure 1 and 2 , providing a circuit substrate 110 .

[0022] In this embodiment, the circuit substrate 110 is a circuit board with conductive lines formed thereon. The circuit substrate 110 includes a first insulating layer 111 , an outer conductive circuit layer 112 , a second insulating layer 113 , an inner conductive circuit layer 114 and a base layer 115 sequentially arranged from top to bottom. The circuit substrate 110 has at least one electromagnetic shielding forming region 110a and a common region 110b except the electromagnetic shielding forming region 110a, and the electromagnetic shielding forming region 110a is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com