Positive plate of lead-acid storage battery and manufacturing method of positive plate

A lead-acid battery and manufacturing method technology, applied in lead-acid battery electrodes, battery electrodes, electrode carriers/current collectors, etc., can solve problems such as unavailability of active materials, softening and falling off batteries, complicated production processes, etc., and achieve easy mechanized operation. , beneficial to mass production and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

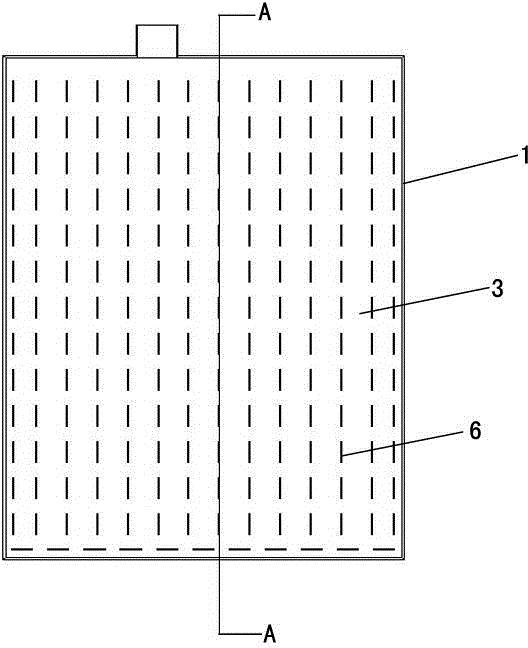

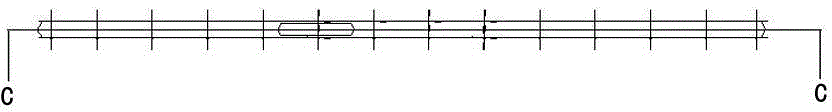

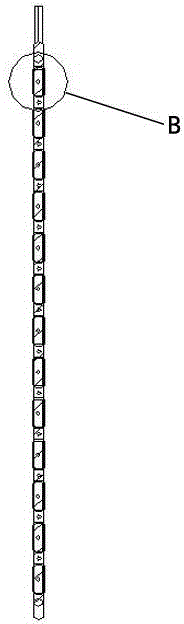

[0032] Such as Figure 1 to Figure 5 As shown, a positive plate of a lead-acid battery of the present invention includes a grid frame body 1 with tabs, a lead paste 2 and an acid-resistant porous coating layer 3, and horizontal ribs 4 and vertical ribs are interlaced in the grid frame body 1 5. The grid frame body 1 is made of high corrosion resistance and high strength lead alloy material, which is preferably made by die-casting process or gravity casting and then rolling process. Slightly thicker than the transverse rib 4, this manufacturing process can enhance the structural strength of the grid frame 1 and ensure the stability of the positive plate shape and structure during the charging and discharging process of the lead-acid battery.

[0033] As a grid structure, the lead paste 2 is filled and coated in the grid frame 1 with the network struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com