Temperature sensor array structure based on tetragonal lattice dielectric post photonic crystal

A technology of temperature sensor and photonic crystal, which is applied to thermometers, thermometers, instruments, etc. with physical/chemical changes. It can solve the problems of narrow band gap, affect integration, and low sensor sensitivity, and achieve low power consumption and accurate detection. High performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

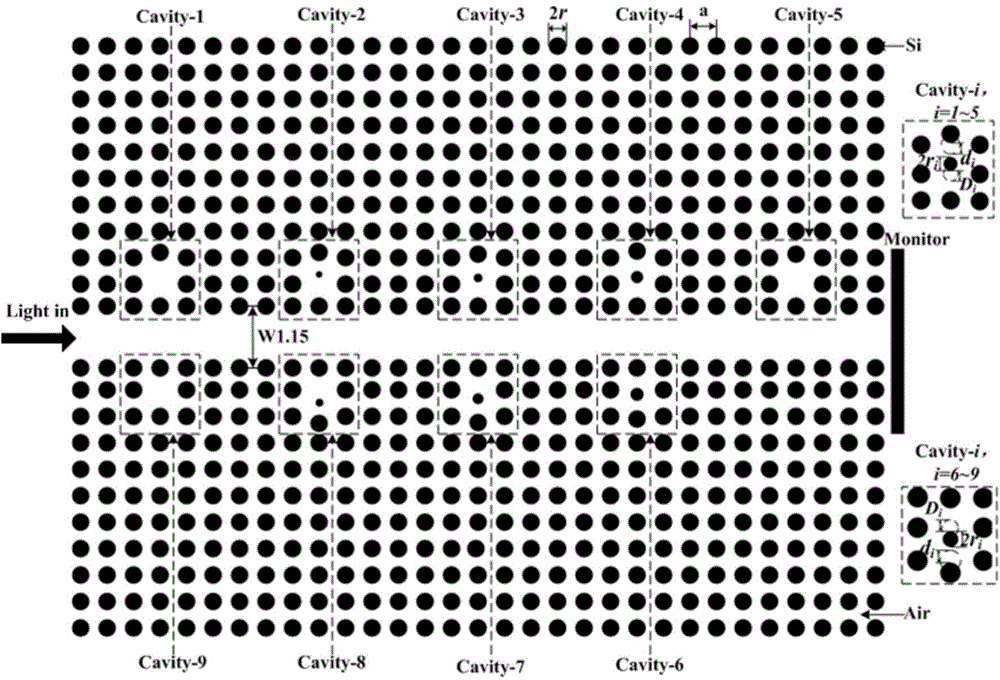

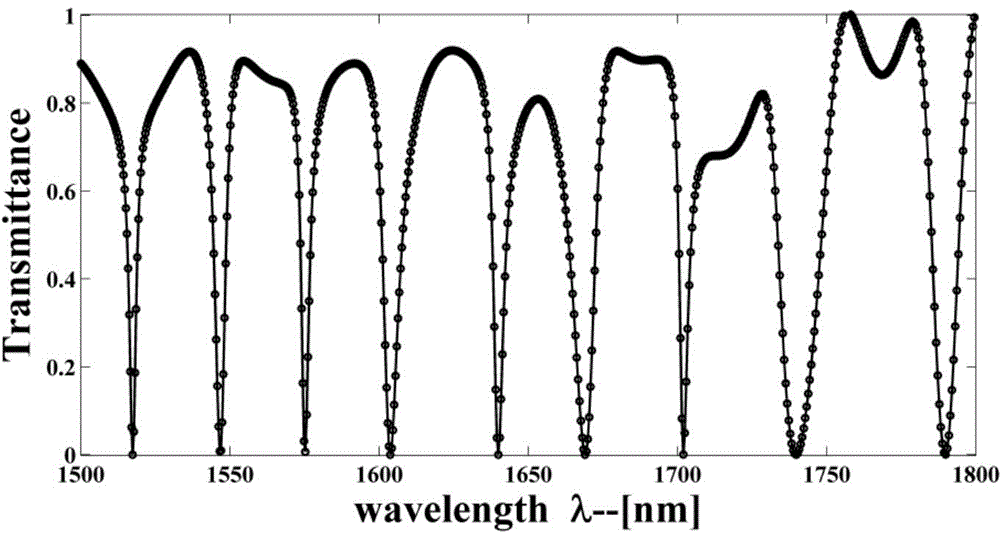

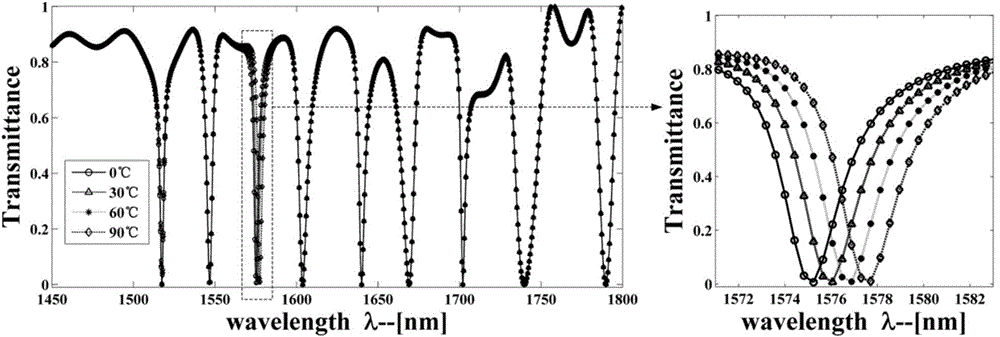

[0036] The structural model of the photonic crystal temperature sensor array of the tetragonal lattice dielectric column is as follows: figure 1 As shown, it contains a W1.15 photonic crystal waveguide and 9 highly efficient coupled photonic crystal resonators. The resonant cavity is composed of 9 adjacent dielectric columns, where the radius of the functional dielectric column is r i , the corresponding displacement is D i , the displacement of the medium column above the functional medium column is d i ;Lattice constant a=600nm, other dielectric column radius r=108nm, the refractive index of background air medium is 1.0, and the refractive index of dielectric column silicon is n si = 3.4. When the structural parameter r of the resonator i ,D i , d i When any one of the parameters changes, the resonant frequency of the resonant cavity will change accordingly. Therefore, the basic structure of the photonic crystal temperature sensor array can be formed by rationally des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com