Low-temperature drying and coal conveying integrated equipment for raw coal

A technology of drying equipment and coal transportation, which is applied in the direction of drying gas arrangement, combustion equipment, progressive dryer, etc., which can solve the problems of reducing the utilization efficiency of coal combustion, affecting the power consumption of coal mills, limiting the exhaust temperature of boilers, etc. Effects of coal utilization efficiency, reduction of moisture content outside raw coal, and improvement of power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention provides an integrated equipment for raw coal low-temperature drying and coal conveying. The present invention will be further described in detail below in conjunction with the accompanying drawings.

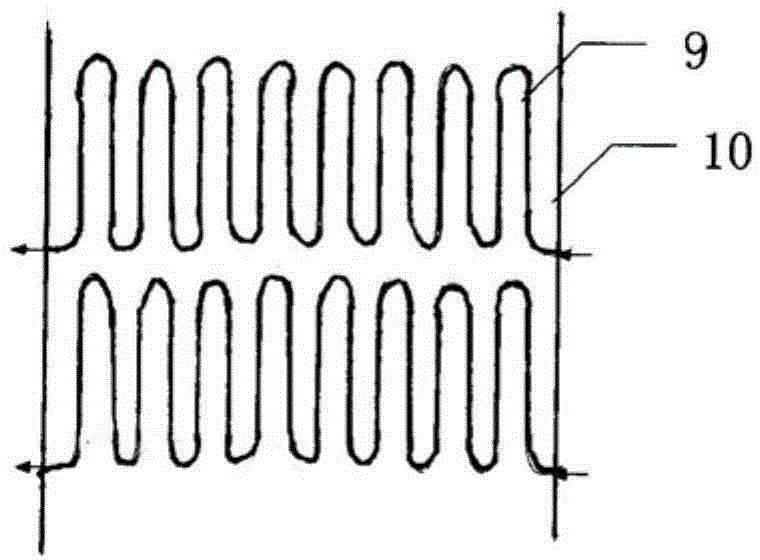

[0022] exist figure 1 , figure 2 , Figure 5 In the schematic diagram of the raw coal low-temperature drying and coal transportation integrated equipment shown, in the coal delivery room 1, the equipment shell 2 and the equipment inner shell 10 form a double-layer closed space, and the air introduction pipe 3 is connected with the drying equipment inner shell 2. The first water medium heater 11 is arranged; the first and second water medium heaters are arranged in rows of serpentine tubes (such as image 3 As shown), the temperature range of the working fluid in the multi-row serpentine tubes is 50-60°C, and the air is heated to 45-55°C to directly heat the coal particles on the crawler belt 6. ; The inside of the crawler belt 6 is sequentially a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com