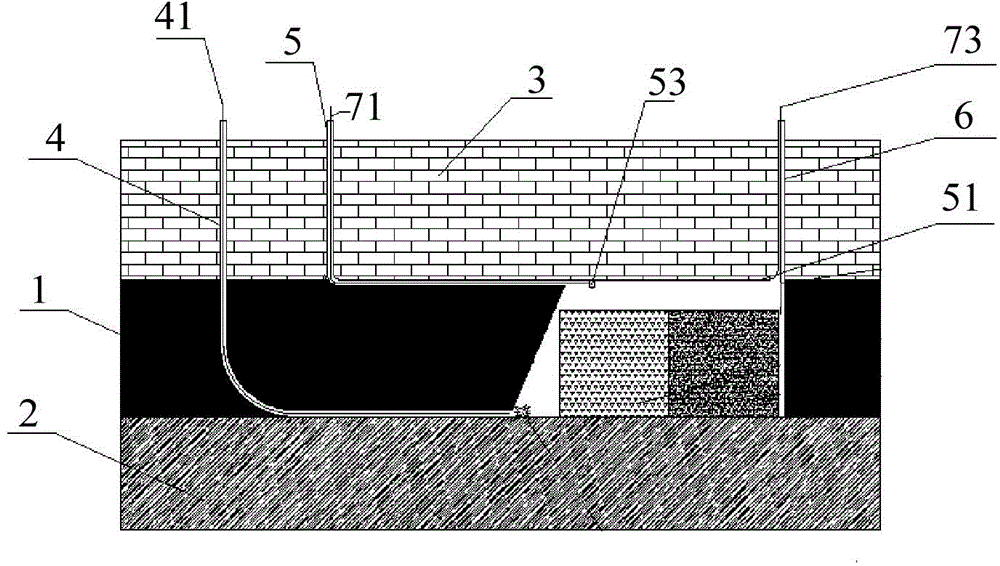

Coal underground gasification system and control method

A technology of underground gasification and control method, which is applied in coal gasification, underground mining, earthwork drilling and other directions, can solve the problems of cumbersome layout of underground gasification production units, impact on personnel safety, etc., and achieves improved stability, combustion quality and structure. The effect of stable strength and avoiding movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

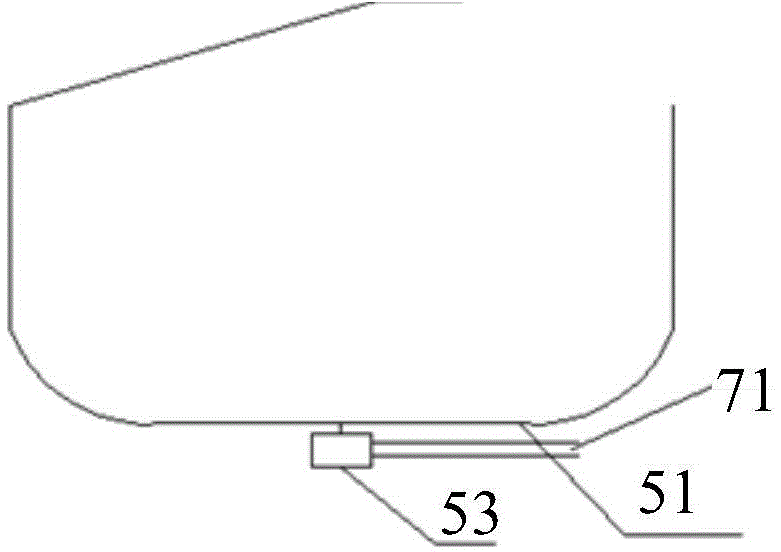

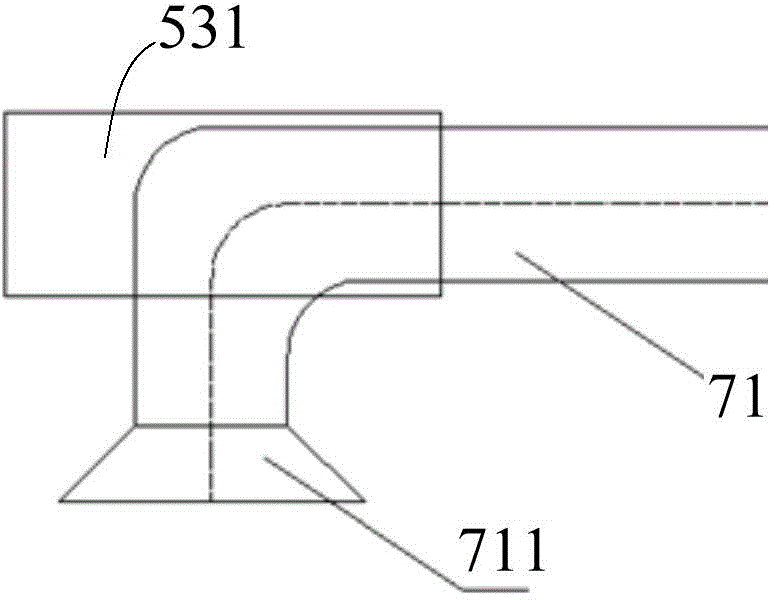

Method used

Image

Examples

Embodiment 1

[0051] with oxygen and CO 2 It is a gasification agent, and the initial intake air volume is 2500Nm 3 / h, the oxygen concentration is about 60%; and the calorific value of gas per unit volume is set to 1400Kcal / Nm 3 , the initial volume V1 is 300m 3 .

[0052] The real-time volume V of the burn-off zone 空 is monitored, when the real-time volume of the burn-out zone V 空 up to 300m 3 Around, and the calorific value per unit volume of gas falls within 1540-1680Kcal / Nm 3 interval, and there is still a downward trend, start filling.

[0053] The flow rate of the filling is converted according to the volume converted from the hourly coal consumption, for example, the hourly coal consumption is 3.5 tons, and the coal density is 1.43 tons / m 3, the amount of filler injected per hour is 2.45m 3 . Continue to monitor the gas composition and the real-time volume of the burn-up area. When the real-time volume of the burn-up area reaches the limit value of the burn-up area, for exa...

Embodiment 2

[0055] Oxygen and air are used as gasification agents, and the initial air intake is 2500Nm 3 / h, the oxygen concentration is about 60%; and the calorific value of gas per unit volume is set to 1000Kcal / Nm 3 , the initial volume V1 is 200m 3 .

[0056] The real-time volume V of the burn-off zone 空 is monitored, when the real-time volume of the burn-out zone V 空 up to 200m 3 Around, and the calorific value per unit volume of gas falls within 1100-1200Kcal / Nm 3 interval, and there is still a downward trend, start filling.

[0057] The flow rate of the filling is converted according to the volume converted from the hourly coal consumption, for example, the hourly coal consumption is 5 tons, and the coal density is 1.43 tons / m 3 , the amount of filler injected per hour is 3.49m 3 . Continue to monitor the gas composition and the real-time volume of the burn-off zone. When the real-time volume of the burn-off zone reaches the volume limit of the burn-off zone, it is the sam...

Embodiment 3

[0059] with oxygen and CO 2 It is a gasification agent, and the initial intake air volume is 2500Nm 3 / h, the oxygen concentration is about 60%; and the calorific value of gas per unit volume is set to 1400Kcal / Nm 3 , the initial volume V1 is 300m 3 .

[0060] The real-time volume V of the burn-off zone 空 is monitored, when the real-time volume of the burn-out zone V 空 up to 300m 3 Around, and the unit gas calorific value falls within 1540-1680Kcal / Nm 3 interval, and there is still a downward trend, start filling. Begin by quickly filling 20% of the burn area with gravel, leaving 80% of the burn area for subsequent filling. Specifically, according to the measured bulk density of gravel is 1500kg / m 3 , then the calculation shows that the required rapid filling capacity is 300×1500×80%=360000kg. Then the remaining 80% of the combustion area is subsequently filled, and the flow rate of the filling is converted according to the volume converted from the hourly coal cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com