Intelligent composite material continuous pipe

A technology of composite materials and coiled tubing, applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problems of unbearable fatigue resistance, poor corrosion resistance, large power consumption, etc., and achieve low operating cost, good mechanical properties, The effect of increasing oil well production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

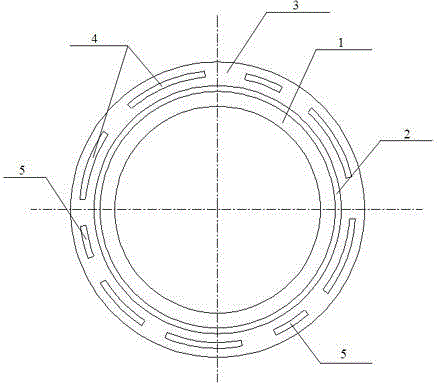

[0015] Refer to attached figure 1 , the intelligent composite continuous pipe of the present invention comprises an inner pipe pressure-bearing sealing layer 1, a resin fiber reinforced layer 2, an outer protective layer 3, a power cord 4 and an optical fiber data line 5, an inner pipe pressure-bearing sealing layer 1, a resin fiber reinforced The layer 2 and the outer protective layer 3 are the whole coiled tubing, the power cord 4 and the optical fiber data cable 5 are the whole cord, and the inner tube pressure sealing layer 1 is wound and braided with a resin fiber reinforced layer 2, and the resin fiber reinforced layer 2 is covered with an outer protection layer 3 , a power line 4 is embedded in the outer protection layer 3 , and an optical fiber data line 5 is embedded in the outer protection layer 3 . The pressure-bearing sealing layer 1 of the inner tube is made of PVDF or cross-linked polyethylene, which has the characteristics of anti-oil acid-base corrosion, the re...

Embodiment 2

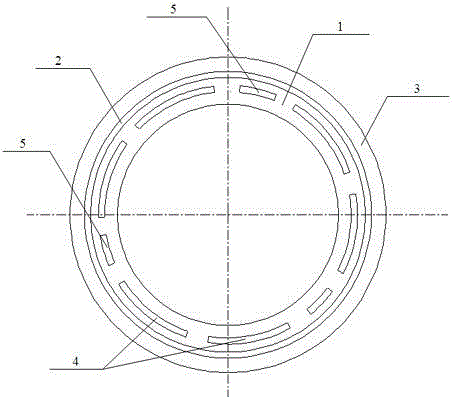

[0020] Refer to attached figure 2 , the difference from the first embodiment is: the optical fiber data line 5 of the intelligent composite material coiled tube is embedded in the pressure-bearing sealing layer 1 of the internal inner tube; the optical fiber data line 5 is a single-mode optical fiber data line, and the intelligent composite material continuous The pipe is lowered into the bottom hole assembly of the drill bit. The bottom hole assembly includes temperature and pressure sensors and a measurement-while-drilling system that can measure well deviation and azimuth.

[0021] One end of the single-mode optical fiber data cable is connected to a downhole temperature sensor, pressure sensor, MWD (wireless measurement while drilling) tool or LWD (wireless logging while drilling) tool, and the other end is connected to a ground receiver to obtain real-time downhole temperature, pressure, Formation gamma resistivity information.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com