LDS electroless plating process

A technology of electroless plating and electroless nickel plating, applied in the field of electroless plating technology, can solve problems affecting the development of copper surface treatment technology, overflow plating of catalytically active products of electroless plating solution, affecting product quality and production cost, etc., to achieve the suppression of overflow plating , Solve the problem of overflow plating, solve the effect of overflow plating phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

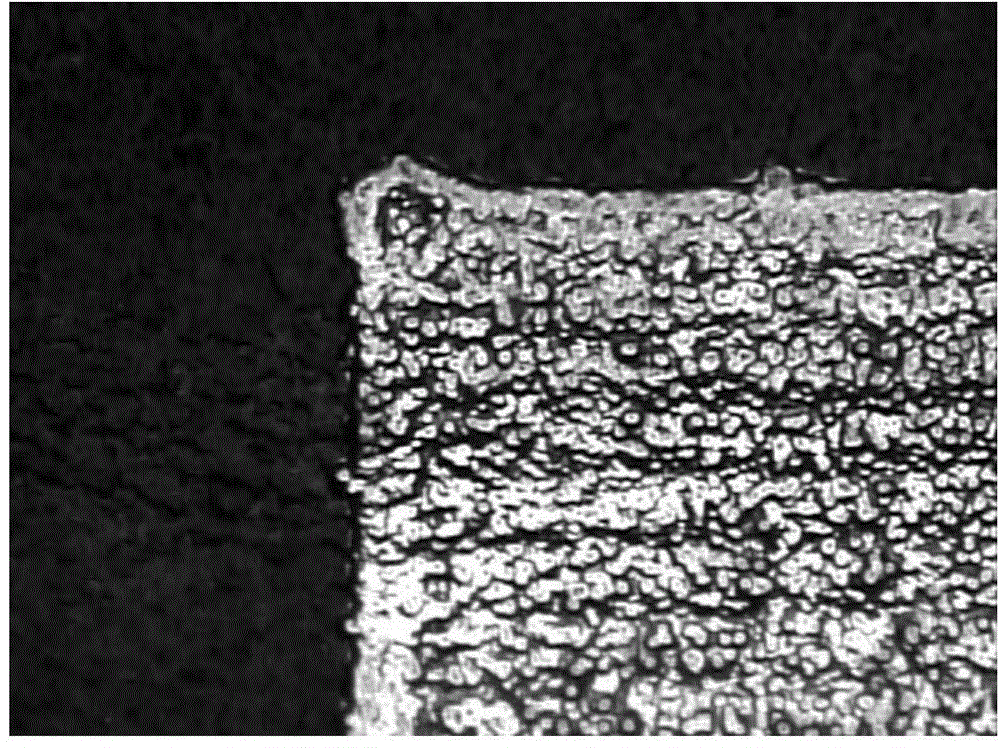

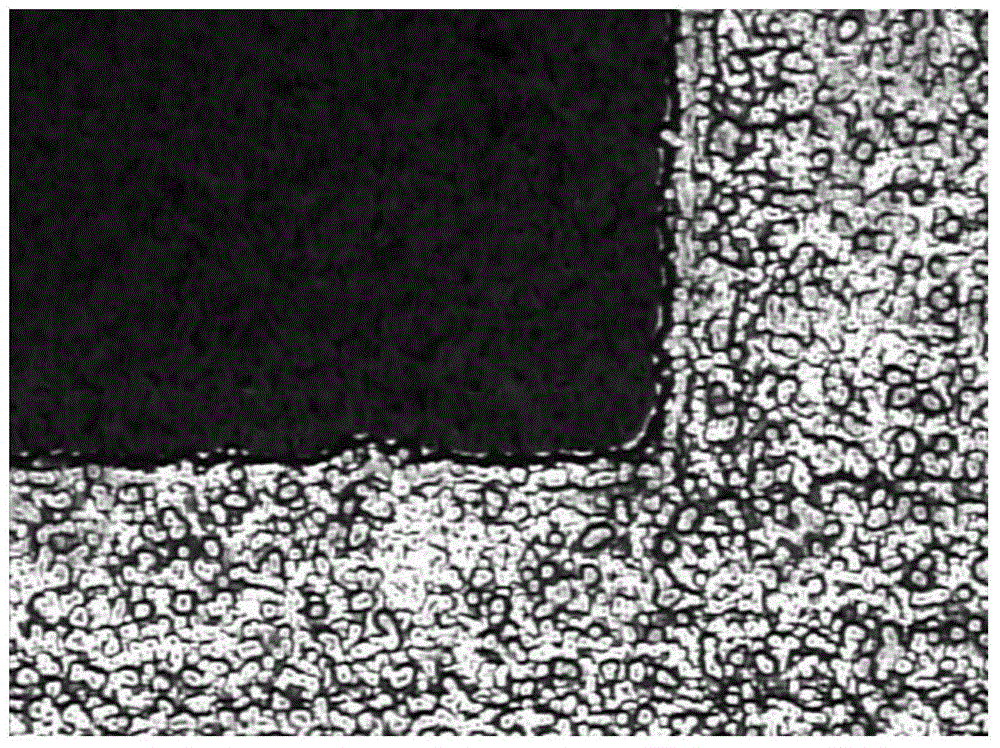

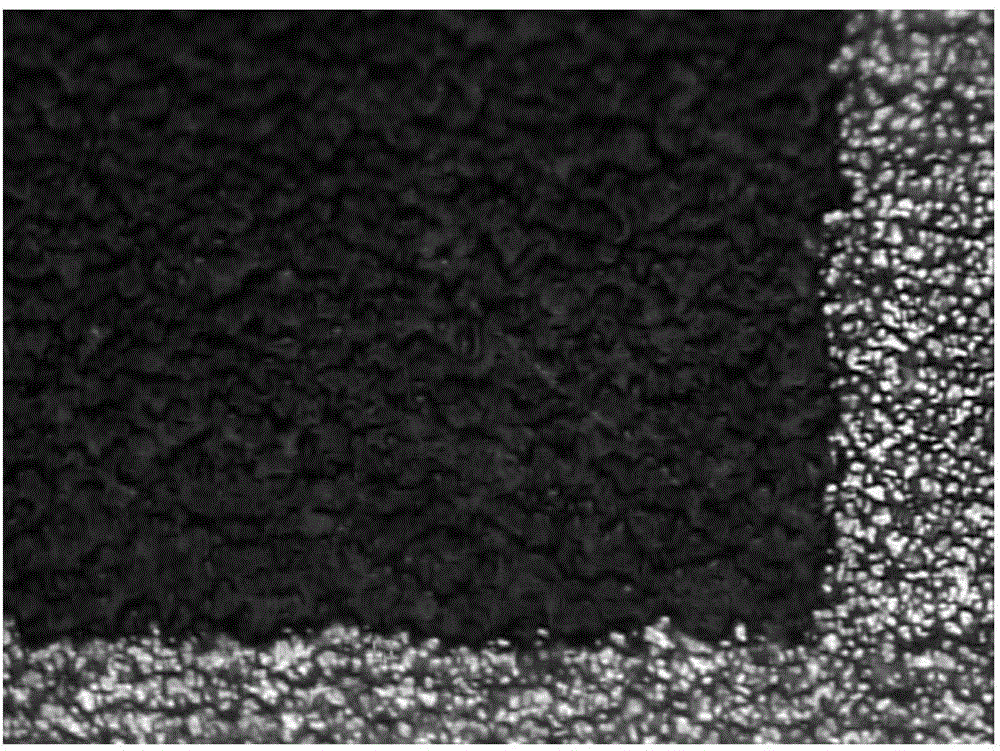

[0072] Using the above-mentioned LDS electroless plating process, the present embodiment has selected two representative mobile phone antenna products, namely: antenna A and antenna B, wherein antenna A and antenna B are made of polycarbonate (PC) and acrylonitrile - Butadiene-styrene copolymer (ABS) is mixed, and the two antenna products are semi-finished products, which are made by laser machine of LPKF company according to different antenna patterns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com