High-strength antifriction aluminum alloy

An aluminum alloy, high-strength technology, applied in the field of aluminum alloys, can solve the problems of reduced overall efficiency, low strength performance, reduced matching accuracy, etc., and achieve the effect of improving strength and anti-friction performance, improving material mechanical properties, and excellent processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

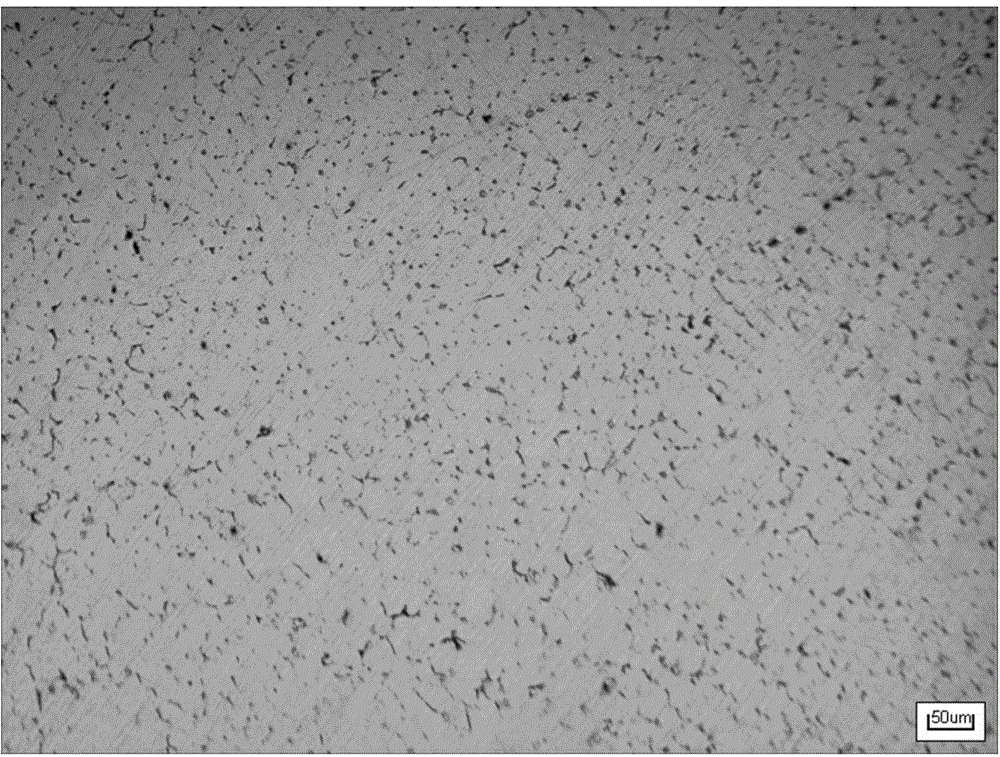

Image

Examples

Embodiment 1

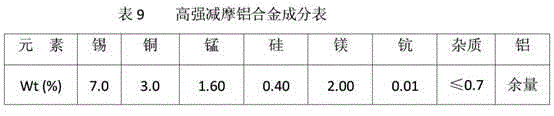

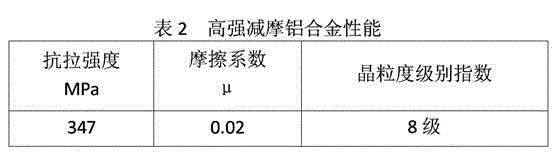

[0017] The high-strength anti-friction aluminum alloy of the present invention is a cast aluminum alloy, and its specific chemical composition is shown in Table 1. The equipment used is a crucible resistance furnace.

[0018] Casting pouring molding process, the specific steps are:

[0019] 1) Ingredients: According to the formula requirements, entrust aluminum alloy material manufacturers to produce remelted aluminum alloy ingots;

[0020] 2) Melting: Heat and melt the aluminum alloy ingot in a crucible boiler at a temperature of 740±5°C;

[0021] 3) Refining and degassing: use powder spraying refining agent to carry out powder spraying and refining on the aluminum alloy solution;

[0022] 4) Hydrogen measurement: The refined aluminum liquid is tested for hydrogen in a vacuum environment <0.02MPa, and cast after passing the hydrogen measurement;

[0023] 5) Pouring molding: Pouring the modified aluminum alloy melt into the mold cavity, and at the same time using the quick ...

Embodiment 2

[0030] For the high-strength anti-friction aluminum alloy of this embodiment, see Table 3 for the specific chemical composition and Table 4 for the properties.

[0031]

[0032]

[0033] The casting pouring molding process and the equipment used in this embodiment are the same as those in Embodiment 1.

Embodiment 3

[0035] For the high-strength anti-friction aluminum alloy of this embodiment, see Table 5 for the specific chemical composition and Table 6 for the properties.

[0036]

[0037]

[0038] The casting pouring molding process and the equipment used in this embodiment are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com