In-situ preparation method of water-based lubricant containing molybdenum disulfide nanosheet

A technology of water-based lubricants and molybdenum disulfide, which is applied in the direction of lubricating compositions, additives, petroleum industry, etc., can solve the problems of unstable dispersion and limited use, and achieve the effect of simple process and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

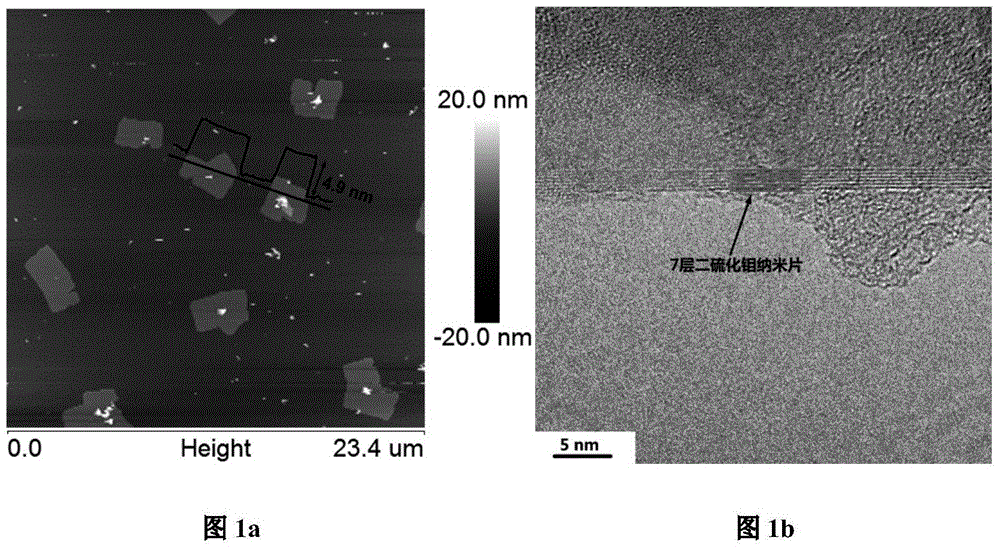

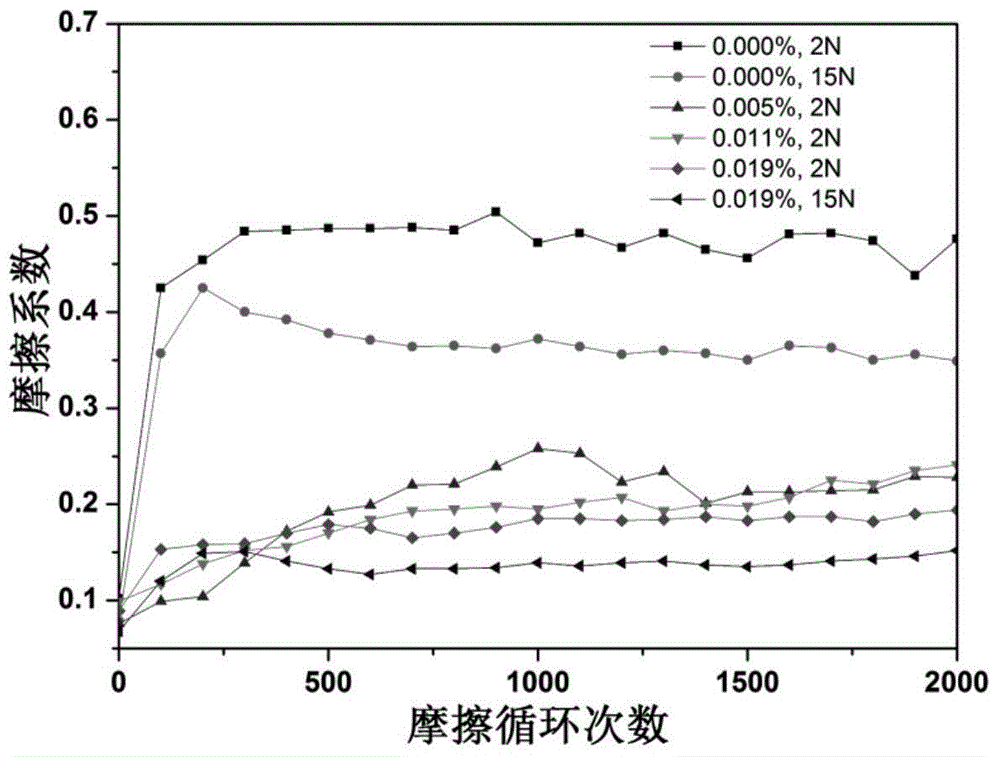

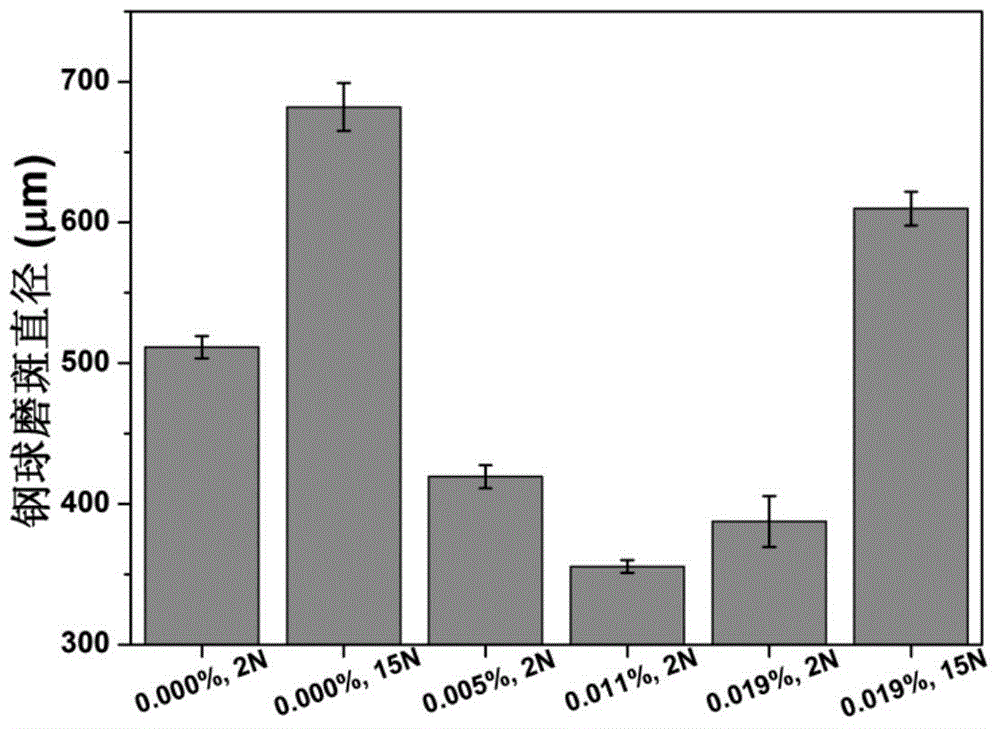

[0042]Step 1: Weigh 0.3g surface modifier Triton X-100, add it into 300mL deionized water, and stir vigorously for 12h to fully dissolve the surface modifier in water to obtain a solution for preparing a water-based lubricant (Triton X- 100 mass ratio is 0.1%);

[0043] Step 2: Weigh 1.5g of molybdenum disulfide powder (particle size less than 325 mesh) and add it to the prepared solution, stir until it is uniformly dispersed to obtain a molybdenum disulfide dispersion (molybdenum disulfide mass ratio 0.5%), and pack it into a conical flask with a lid;

[0044] Step 3: Dip the Erlenmeyer flask containing the molybdenum disulfide dispersion in the container of the ultrasonic cavitation generating device (filled with water in advance), perform ultrasonic cavitation treatment for 8 hours, and keep the container in the container by means of circulating cooling during this period. The water temperature is lower than 40°C; the power of the ultrasonic cavitation generator is 120W, a...

Embodiment 2

[0049] Step 1: Weigh 0.3g of surface modifier Triton X-100, add 300mL of deionized water, and vigorously stir for 12 hours to fully dissolve the surface modifier in water to obtain a solution for preparing a water-based lubricant (Triton X-100 -100 mass ratio is 0.1%);

[0050] Step 2: Weigh 3g of molybdenum disulfide powder (particle size less than 325 mesh) and add it to the prepared solution, stir until it is evenly dispersed to obtain a molybdenum disulfide dispersion (molybdenum disulfide mass ratio 1%), and put it into In a Erlenmeyer flask with a lid;

[0051] Step 3: Dip the Erlenmeyer flask containing the molybdenum disulfide dispersion in the container of the ultrasonic cavitation generating device (filled with water in advance), perform ultrasonic cavitation treatment for 8 hours, and keep the container in the container by means of circulating cooling during this period. The water temperature is lower than 40°C; the power of the ultrasonic cavitation generator is 1...

Embodiment 3

[0056] Step 1: Weigh 0.3g of surface modifier Triton X-100, add 300mL of deionized water, and vigorously stir for 12 hours to fully dissolve the surface modifier in water to obtain a solution for preparing a water-based lubricant (Triton X-100 -100 mass ratio is 0.1%);

[0057] Step 2: Weigh 6g of molybdenum disulfide powder (particle size less than 325 mesh) and add it to the prepared solution, stir until it is evenly dispersed to obtain a molybdenum disulfide dispersion (molybdenum disulfide mass ratio 2%), and put it into In a Erlenmeyer flask with a lid;

[0058] Step 3: Dip the Erlenmeyer flask containing the molybdenum disulfide dispersion in the container of the ultrasonic cavitation generating device (filled with water in advance), perform ultrasonic cavitation treatment for 8 hours, and keep the container in the container by means of circulating cooling during this period. The water temperature is lower than 40°C; the power of the ultrasonic cavitation generator is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com