A kind of high modulus asphalt particle and preparation method thereof for road construction

A kind of asphalt granule and high modulus technology, applied in the direction of construction, building components, building structures, etc., can solve problems such as energy waste, safety hazards, environmental pollution, etc., and achieve the effect of reducing processing procedures, reducing costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

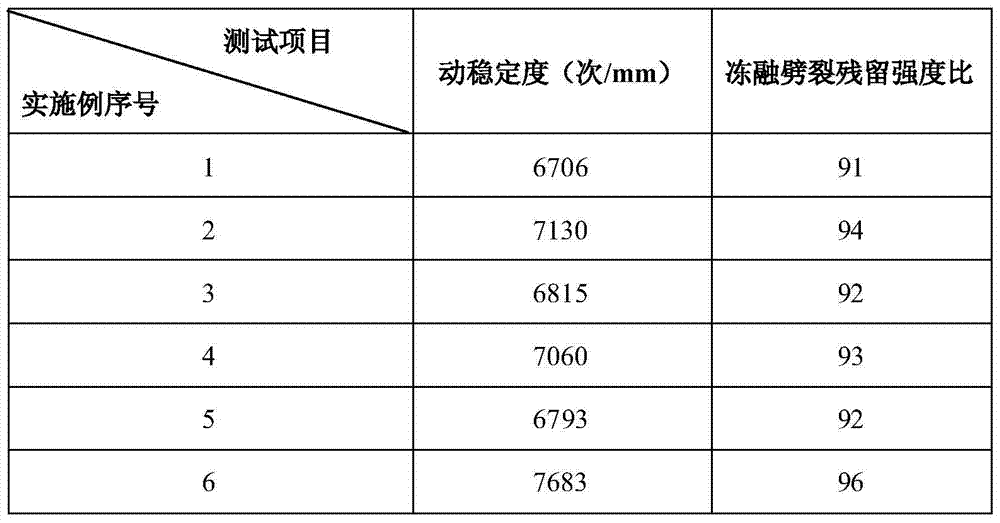

Examples

Embodiment 1

[0025] 1) Combine 5 parts of recycled polyethylene, 10 parts of recycled polypropylene, 2 parts of SBS, 3 parts of EVA, 2 parts of 2,6-di-tert-butyl-4-cresol, 2 parts of petroleum resin, and 1 part of rosin resin with Shell 90 # 75 parts of asphalt were sheared and stirred at 3500rpm at 175°C for 10-20min, then added 3 parts of MAH, 0.5 part of dicumyl peroxide, 0.5 part of zinc oxide and 0.5 part of sulfur, and sheared at 165°C at 2500rpm Stir for 10 minutes to obtain modified asphalt.

[0026] 2) Pass 50 parts of modified asphalt and 50 parts of nano-calcium carbonate through a twin-screw extruder to make modified asphalt granules.

Embodiment 2

[0028] 1) Mix 10 parts of recycled polyethylene, 5 parts of recycled polypropylene, 1.5 parts of diphenylisodecyl phosphite, 3.5 parts of rosin resin with Shell 90 # 80 parts of asphalt were sheared and stirred at 3500 rpm for 10-20 minutes at 175°C, then 2.5 parts of MAH and 1 part of ditoluyl peroxide were added, and sheared and stirred at 2500 rpm for 10 minutes at 165°C to obtain modified asphalt.

[0029] 2) Pass 60 parts of modified asphalt and 40 parts of nano-calcium carbonate through a twin-screw extruder to make modified asphalt granules.

Embodiment 3

[0031] 1) Mix 15 parts of SBS, 1 part of AO-80 anti-aging agent, 2 parts of rosin resin, 2 parts of petroleum resin with Shell 90 # 80 parts of asphalt were sheared and stirred at 175°C at 3500rpm for 10-20min, then 2 parts of MAH and 1 part of sulfur were added, and sheared and stirred at 165°C at 2500rpm for 10min to obtain modified asphalt.

[0032] 2) Pass 60 parts of modified asphalt and 40 parts of nano-calcium carbonate through a twin-screw extruder to make modified asphalt granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com