A polyvinyl chloride dipped plastic composition resistant to seawater extraction

A technology that is resistant to seawater extraction and polyvinyl chloride, applied in the field of plastic dipping processing, can solve the problems of shortening the service life of gabion nets, poor water resistance and extraction, and polluting the marine environment, achieving good application value and market prospects, and solvent-resistant extraction Good performance, no pollution to the environment

Active Publication Date: 2017-01-11

CHINA PETROLEUM & CHEM CORP

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Chinese patent CN1709963A discloses a polyvinyl chloride hot-dip plastic preparation and its production method and application. The raw materials of the formula are polyvinyl chloride resin powder, dioctyl phthalate, epoxidized soybean oil, and dioctyl sebacate , diisodecyl adipate, flame retardant, stabilizer, fumed silica, etc. The small molecule plasticizers used in this invention all have the defects of easy migration and poor water resistance. The composition will become brittle after long-term use, thereby shortening the service life of the gabion

Polyvinyl chloride is widely used in marine aquaculture equipment, but at present, polyvinyl chloride coated or dipped gabion materials use small molecule plasticizers, which are easily drawn out by seawater and pollute the marine environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

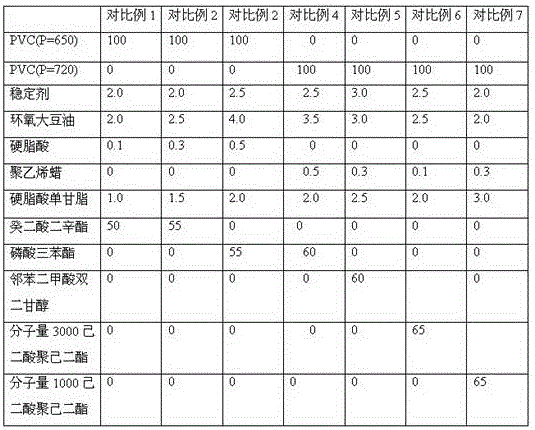

Comparison scheme

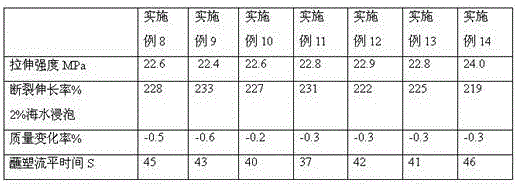

Effect test

Embodiment Construction

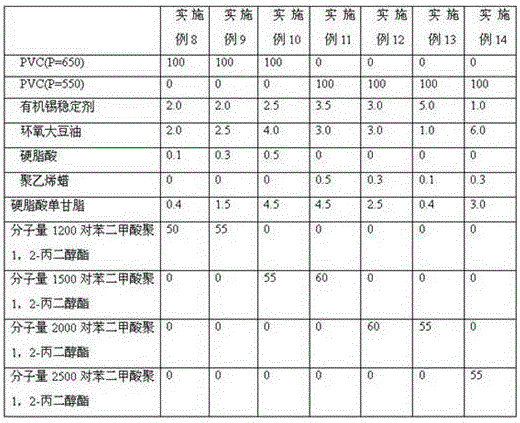

[0022] A kind of polyvinyl chloride plastic dipping composition resistant to seawater extraction of the present invention will be further described through specific examples below, wherein Example 1 is the best example.

[0023]

[0024]

[0025]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a seawater-pumping-resistant polyvinyl chloride dipping composite, and belongs to the technical field of dipping processing. The composite is characterized by being prepared by taking 50-60 parts by weight of polydiethylene glycol adipate or poly (1,2-trimethylene terephthalate) with number-average molecular weight of 1200-3000 as a plasticizer, taking 100 parts by weight of suspension method polyvinyl chloride resin with polymerization degree of 550-650 as a main raw material, taking 1.0-5.0 parts by weight of stabilizer, 1.0-6.0 parts by weight of auxiliary stabilizer and 0.5-5.0 parts by weight of lubricant as auxiliary materials, performing hot mixing and stirring, performing cooling and sieving with a 50-mesh filter screen. The composite is in a loose and uniform powder state. The composite has water resistance, corrosion resistance and acid-alkali resistance by dipping or molding on an outer layer of a metal wire of a double-twisted wire mesh, has decorative and attractive effects, and resists in long-term seawater pumping; and components do not migrate to the surface, so that the composite is environment-friendly and does not pollute an environment.

Description

technical field [0001] The invention discloses a polyvinyl chloride plastic-dipping composition resistant to seawater extraction, which belongs to the technical field of plastic-dipping processing. Background technique [0002] Plastic dipping is a method of preheating the surface-treated metal parts to the melting temperature range of the plastic, dipping the metal parts into resin powder or resin paste, and making plastic-coated metal parts after plasticizing and cooling. processing methods. Gabion mesh is also called double-twisted wire mesh, commonly known as honeycomb hexagonal mesh. The base material is stretched hot-rolled steel wire. After hot-dip galvanizing and anti-rust treatment, it is woven into twisted-twisted and hexagonal mesh mesh by machine, and then combined with polyvinyl chloride (PVC) dipped in plastic. After that, the net cage or guardrail mesh with antiseptic effect is obtained. Gabion mesh, a steel-plastic composite mesh, can be designed according...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L27/06C08L67/02C09D127/06C09D167/02C09D7/12

CPCC08L27/06C08L2205/03C09D7/40C09D127/06C08L67/02C08K5/57C08K5/1515C08K5/09C08K5/103C08L23/06

Inventor 李静刘容德刘浩张桦李兆华桂俊杰孙培培王晶张新华

Owner CHINA PETROLEUM & CHEM CORP

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com