Jacket steel-lined plastic corrosion-prevention high-voltage-resistance pipe fitting and manufacturing method

A technology of high pressure resistance and inner lining, which is applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., which can solve the problems of easy corrosion of steel pipe fittings, short service life, and failure to meet the use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

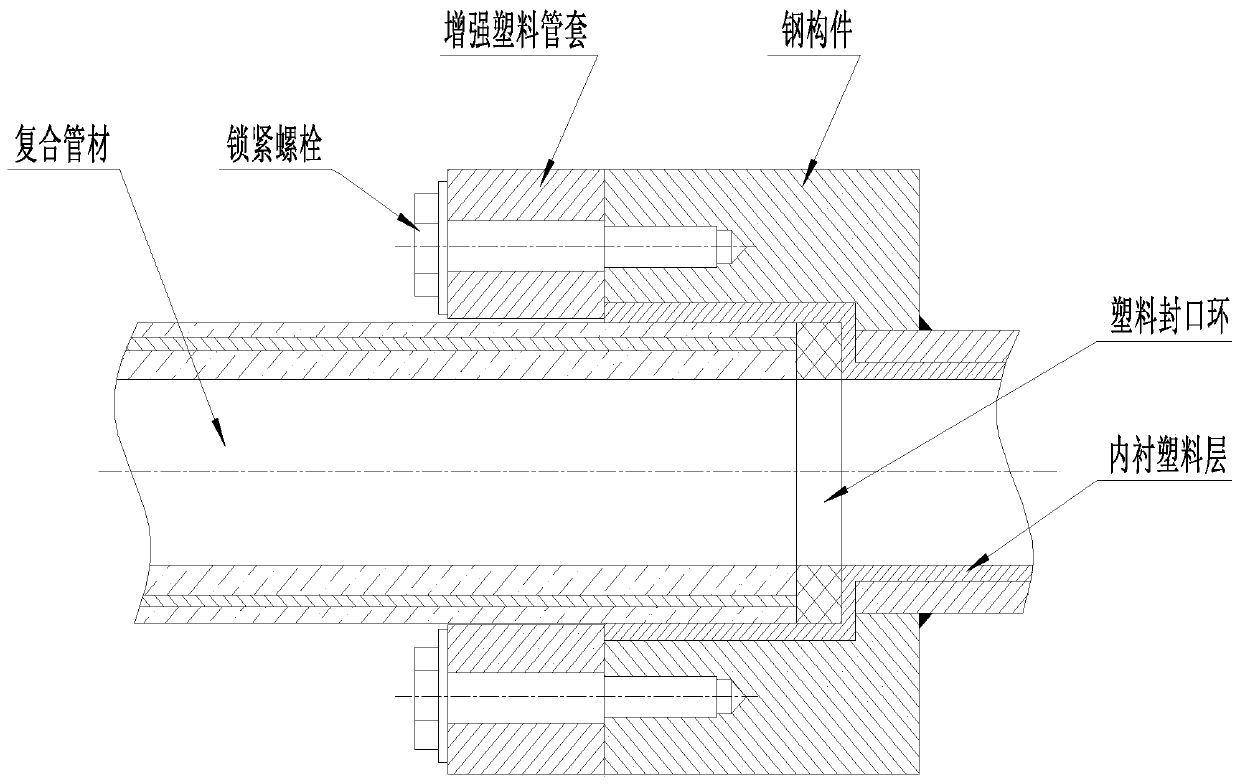

[0029] Such as figure 1 As shown, including the steel body of the jacket, the thermoplastic lining and the reinforced plastic pipe sleeve, in the structural design of the entire pipe fitting, the steel casing of the jacket plays the role of bearing the hoop stress, the thermoplastic lining plays the role of anti-corrosion, and the reinforced plastic The pipe sleeve plays the role of anti-axial stress.

[0030] The jacket steel body includes the receiving section at both ends and the transfer section in the middle. The connection between the two ends of the transfer section and the corresponding receiving section is formed by external electric welding. There are several equidistant ports around the port of the receiving section. Bolt holes, the transfer section can be elbow, tee, direct, flange, etc., the thermoplastic lining includes the thermoplastic lining of the receiving section at both ends and the thermoplastic lining of the transition section in the middle. The connect...

Embodiment 2

[0032] The invention also discloses a method for manufacturing a steel-lined plastic-coated anti-corrosion and high-pressure resistant pipe fitting, which includes the following steps:

[0033] A1. Select the receiving section whose inner diameter is 8mm to 20mm larger than the outer diameter of the external composite pipe, and the wall thickness of the receiving section should be greater than the diameter of the tie bolt + 8mm or more;

[0034] A2. Select the transition section whose nominal diameter is equal to the inner diameter of the external composite pipe, and weld and fix the root of the finished product of the transition section with the port of the transition section to form a jacket steel body;

[0035] A3. Heat the steel body of the jacket to 250°C-400°C as a whole, keep the steel body of the jacket at 200°C-250°C with a built-in thermoplastic powder coating plastic melt, and after natural cooling and shaping to obtain the inner-lined thermoplastic body, clean the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com