High-bending strength oxidized carbon nanomaterial/carbon fiber/epoxy resin composite material and preparation method thereof

A technology for oxidizing nano-carbon and composite materials, applied in the field of composite materials, can solve the problems of improving the performance of nano-carbon materials/carbon fiber/epoxy resin composite materials, production and application limitations, unfavorable industrialized production, long reaction routes, etc. The effect of outstanding performance, environmental protection and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

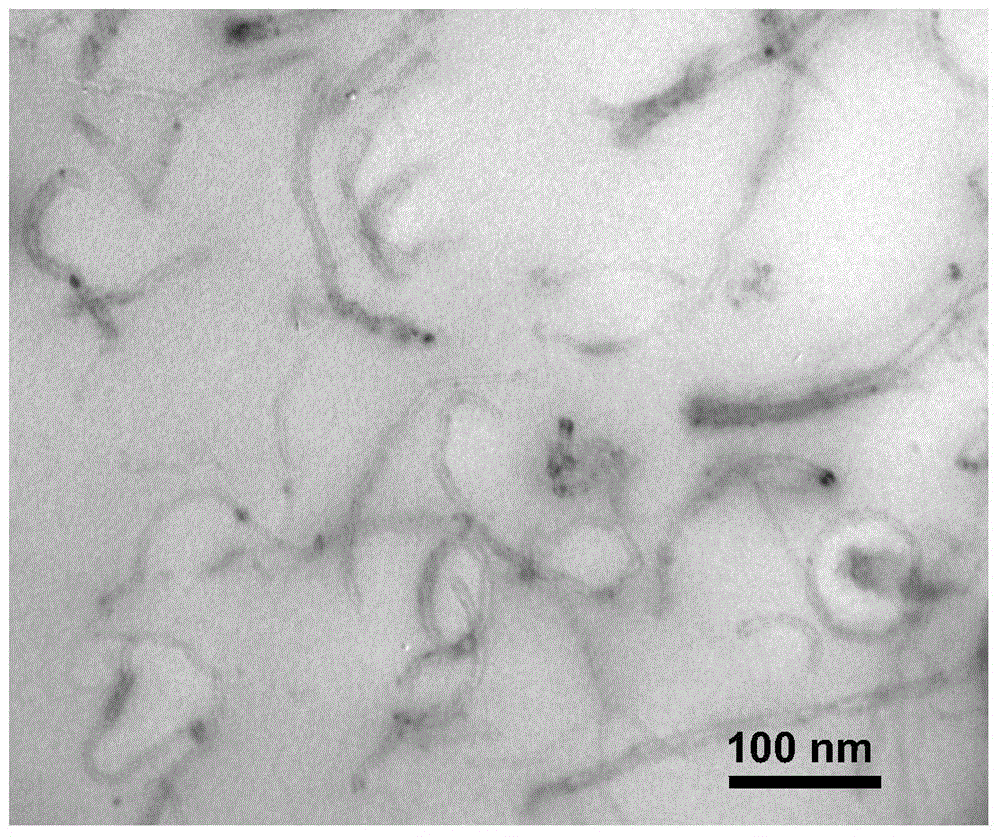

Image

Examples

Embodiment 1

[0072] Triglycidyl p-aminophenol and graphene oxide aqueous dispersion with a mass concentration of 0.1wt% are mixed at room temperature at a weight ratio of 1:250, and mechanically stirred at a speed of 100 rpm at 25°C for 2 minutes, then ready It is observed that the water phase becomes clear, and the graphene oxide is all transferred to the triglycidyl p-aminophenol, and the clear water is poured out, and the mixture is heated at 230° C. in a vacuum oven for 2 minutes to obtain graphene oxide / Triglycidyl p-aminophenol mixture. Add 62.5 parts by weight of triglycidyl p-aminophenol to 14.5 parts by weight of the above mixture for dilution, and then add 23 parts by weight of curing agent thiomethyltoluenediamine. In order to determine the content of graphene oxide, a small amount of the mixture was heated and solidified at 200°C, and then the weight content of graphene oxide was determined to be 3wt% by thermogravimetric method. Its test temperature ranges from room temperat...

Embodiment 2

[0075] Triglycidyl p-aminophenol and graphene oxide water dispersion with a mass concentration of 0.5wt% are mixed at room temperature at a weight ratio of 1:5, and mechanically stirred at a speed of 1000 rpm at 10°C for 4 minutes. It is observed that the water phase becomes clear, and the graphene oxide is all transferred to triglycidyl p-aminophenol, and the clear water is poured out, and the mixture is heated at 170° C. in a vacuum drying oven for 10 minutes to obtain graphene oxide / Triglycidyl p-aminophenol mixture. Add 5 parts by weight of the mixture to 70 parts by weight of triglycidyl p-aminophenol for dilution, and then add 25 parts by weight of curing agent thiomethyltoluenediamine. The weight content of graphene oxide was measured to be 0.1wt%. The graphene oxide / epoxy resin / curing agent mixture was composited with unidirectional carbon fiber cloth (T300, Toray, Japan) by hand lay-up method, cured under pressure on a flat vulcanizer, cured at 170°C for 3 hours, an...

Embodiment 3

[0077] Triglycidyl p-aminophenol and graphene oxide aqueous dispersion with a mass concentration of 0.25wt% were mixed at room temperature with a weight ratio of 1:10, and after mechanical stirring at 100 rpm at 25°C for 0.5 minutes, the aqueous phase When it becomes clear, the graphene oxide is all transferred to triglycidyl p-aminophenol, the clear water is poured out, and the mixture is heated to 230°C for spray drying, and the heating time is 2 minutes to obtain graphene oxide / triglycidyl p-Aminophenol mixture. 10 parts by weight of the mixture were diluted with 60 parts by weight of triglycidyl p-aminophenol, and then 30 parts by weight of curing agent diaminodiphenyl sulfone was added. It is measured that the weight content of graphene oxide is 0.2wt%. The graphene oxide / epoxy resin / curing agent mixture was composited with unidirectional carbon fiber cloth (T300, Toray, Japan) by hand lay-up, and cured under pressure on a flat vulcanizer, cured at 170°C for 1 hour, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com