Highly moisture permeable modified polyurethane and preparation method thereof

A polyurethane, moisture-permeable technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of easy phase separation, poor solubility of silicone, high cost of industrial-scale production, and achieve the effect of improving material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] This program produces 1000g of dihydroxy polysiloxane modified polyether polyol polyurethane, each with base material JB-780G and fabric JS-830G.

[0014] JB-780G production plan is as follows:

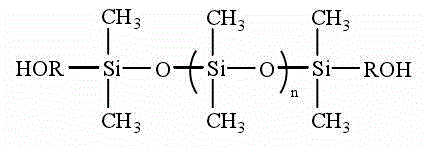

[0015] Raw materials: polyethylene glycol DC-07 (molecular weight 1000, Decheng Company), polyethylene glycol DC-04 (molecular weight 2000, Decheng Company), polypropylene glycol PS-30 (molecular weight 2000, Decheng Company), polysilicon Diol OS-0526 (molecular weight 800), polytetrahydrofuran diol DC-05 (molecular weight 2000, Decheng Company), 1,4 butanediol 1.4BD (molecular weight 160), nitrogen nitrogen dimethyl formamide DMF (chemically pure ), 4,4-diphenylmethane diisocyanate MDI (chemically pure, Yantai Wanhua), toluene TOL (chemically pure), butanone MEK (chemically pure), 2-(2'-hydroxy-5'-tert-ethyl Phenyl)benzotriazole UV-5411 (molecular weight 323), 1, 6-hexamethylene-bis(N,N-dimethylsemicarbazide) HN-130 (molecular weight 196).

[0016] Synthetic route: Take a 1K...

Embodiment 2

[0021] This program produces 1000g of dihydroxy polysiloxane modified polyether polyol polyurethane, each with base material JB-781G and fabric JS-831G.

[0022] JB-781G production plan is as follows:

[0023] Raw materials: polyethylene glycol DC-07 (molecular weight 1000, Decheng Company), polyethylene glycol DC-04 (molecular weight 2000, Decheng Company), polypropylene glycol PS-30 (molecular weight 2000, Decheng Company), polysilicon Diol OS-0526 (molecular weight 800), polytetrahydrofuran diol DC-05 (molecular weight 2000, Decheng Company), 1,4 butanediol 1.4BD (molecular weight 160), trimethylpentanediol TPMD (molecular weight 100.00, Decheng Company), nitrogen nitrogen dimethylformamide DMF (chemically pure), 4,4-diphenylmethane diisocyanate MDI (chemically pure, Yantai Wanhua), toluene TOL (chemically pure), butanone MEK (chemically pure Pure), 2-(2'-hydroxy-5'-tert-octylphenyl)benzotriazole UV-5411 (molecular weight 323), 1, 6-hexamethylene-bis(N,N-dimethylamino Ure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com