Preparation method of bismuth titanate (BT) ferroelectric film

A ferroelectric thin film, bismuth titanate technology, used in chemical instruments and methods, titanium compounds, iron compounds, etc., to achieve strong activity and oxidation, ensure ferroelectric properties, and promote decomposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

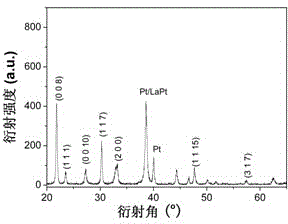

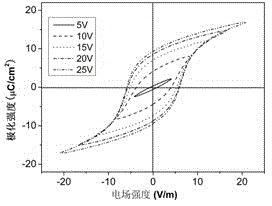

Image

Examples

Embodiment 1

[0038] Mix solution A and solution B according to the molar ratio Bi:Ti=4:3 to obtain a mixed solution;

[0039] By adjusting the amount of methanol, the total concentration of Bi and Ti ions in the mixed solution is controlled at 0.3mol / l.

[0040] After the obtained mixed solution was left to stand for 24 to 48 hours, ammonia water and nitric acid were added according to the molar ratio of Ti: ammonia water: nitric acid = 1:3:3, and the BT precursor solution was obtained;

[0041] 2) Preparation of BT gel film

[0042] Using the BT precursor solution obtained in step 1), a BT gel film was prepared on a Si substrate coated with a Pt conductive layer by pulling or spin coating;

[0043] 3) Pretreatment of BT gel membrane

[0044] Place the BT gel film obtained in step 2) on a heating plate at 300°C, and irradiate the BT gel film with an ultraviolet lamp with a wavelength of 184-254nm for 50 minutes to obtain a BT precursor film;

[0045] 4) Final treatment of BT precursor f...

Embodiment 2

[0053] Mix solution A and solution B according to 4:3, and mix according to the molar ratio Bi:Ti=4:3 to obtain a mixed solution;

[0054] By adjusting the amount of methanol, the total concentration of Bi and Ti ions in the mixed solution is controlled at 0.4mol / l.

[0055] After the obtained mixed solution was left to stand for 24 to 48 hours, ammonia water and nitric acid were added according to the molar ratio of Ti: ammonia water: nitric acid = 1:3:3, and the BT precursor solution was obtained;

[0056] 2) Preparation of BT gel film

[0057] Using the BT precursor solution obtained in step 1), the LaNiO 3 On the Si substrate of the conductive layer, a BT gel film is prepared by pulling or spin coating;

[0058] 3) Pretreatment of BT gel film

[0059] Place the BT gel film obtained in step 2) on a heating plate at 300°C, and irradiate the BT gel film with an ultraviolet lamp with a wavelength of 184-254nm for 40 minutes to obtain a BT precursor film;

[0060] 4) Final ...

Embodiment 3

[0068] Mix solution A and solution B according to the molar ratio Bi:Ti=4:3 to obtain a mixed solution;

[0069] By adjusting the amount of methanol, the total concentration of Bi and Ti ions in the solution is controlled at 0.5 mol / l.

[0070] After the obtained mixed solution was left to stand for 24 to 48 hours, ammonia water and nitric acid were added according to the molar ratio of Ti: ammonia water: nitric acid = 1:3:3, and the BT precursor solution was obtained;

[0071] 2) Preparation of BT gel film

[0072] Using the BT precursor solution obtained in step 1), a BT gel film was prepared on a Si substrate coated with a Pt conductive layer by pulling or spin coating;

[0073] 3) Pretreatment of BT gel membrane

[0074] Place the BT gel film obtained in step 2) on a heating plate at 250°C, and irradiate the BT gel film with an ultraviolet lamp with a wavelength of 184-254nm for 40 minutes to obtain a BT precursor film;

[0075] 4) Final treatment of BT precursor film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com