Solar photovoltaic panel protective film

A solar photovoltaic panel and protective film technology, applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of light energy loss, high refractive index of glass, and limited applications, etc., to increase corrosion resistance and wear resistance, improved chemical and physical properties, and low radiation absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

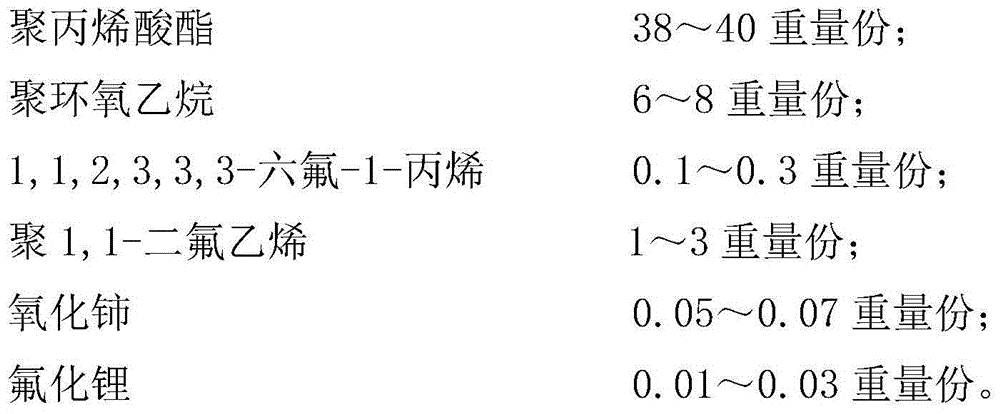

[0022] This case proposes a protective film for solar photovoltaic panels, including an optical PET layer and a protective coating on the surface of the optical PET layer. The protective coating is composed of the following materials by weight:

[0023]

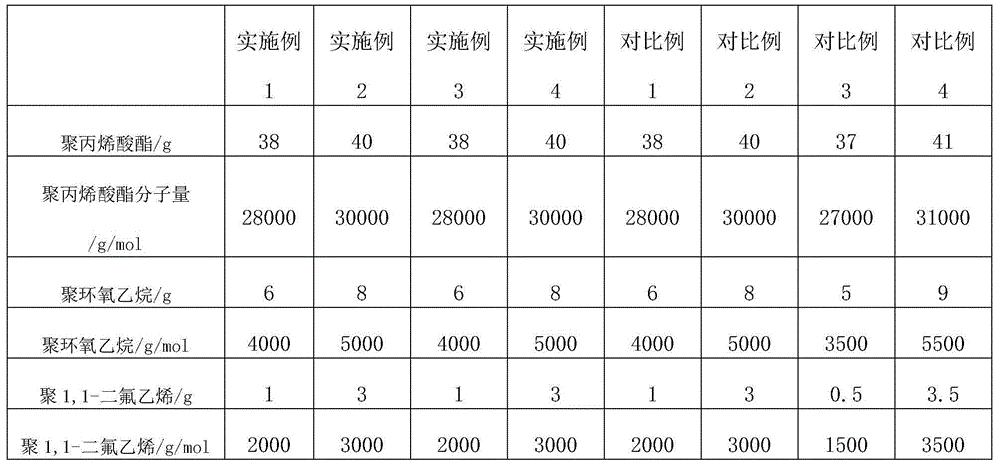

[0024] Polyacrylate has high optical transmittance, which satisfies the light transmittance requirements of photovoltaic panel protective film, but the number average molecular weight of polyacrylate will determine the physical and optical properties of the polymer, so its number The average molecular weight must be limited, preferably 28,000 to 30,000g / mol; if the number average molecular weight is less than 28,000g / mol, the mechanical processing performance of the film will be reduced, making it unable to meet the requirements for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com