Disk-like glass substrate with magnetic recording medium and manufacturing method thereof

A magnetic recording medium and glass substrate technology, which is applied in glass manufacturing equipment, magnetic recording, disk-shaped carriers, etc., can solve the problems of glass substrate defects, cracks, and residual processing cracks, so as to improve production efficiency, suppress defects, and increase tension. number effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, modes for implementing the present invention will be described with reference to the drawings.

[0029] 〔Structure of Laser Processor〕

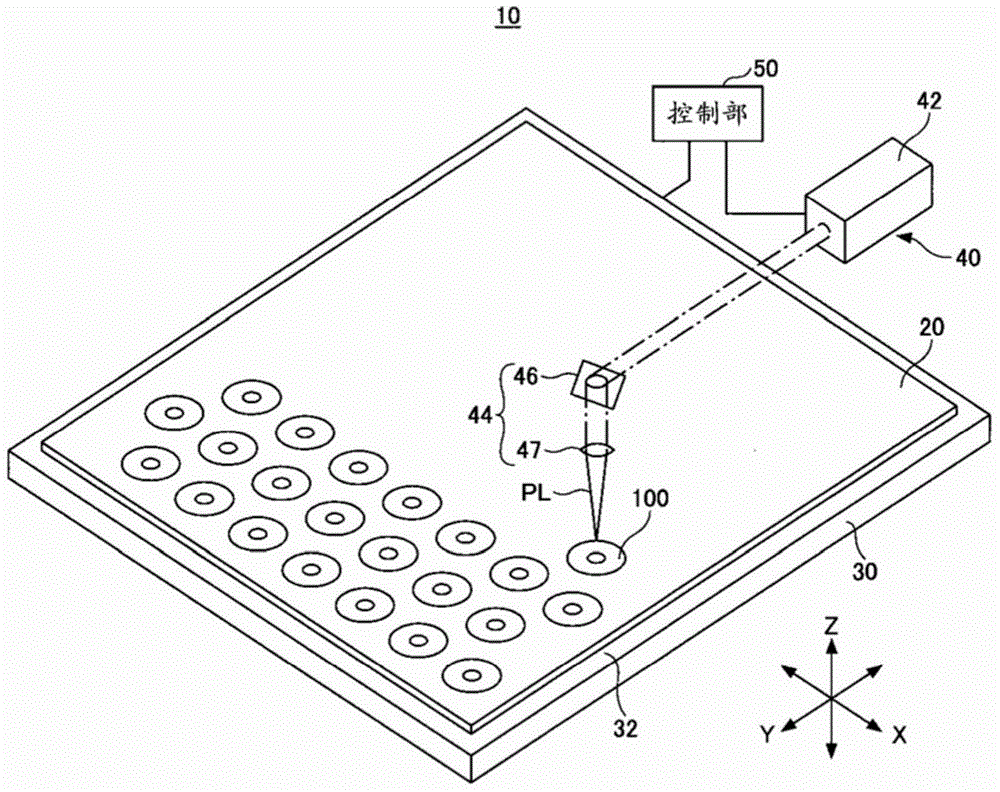

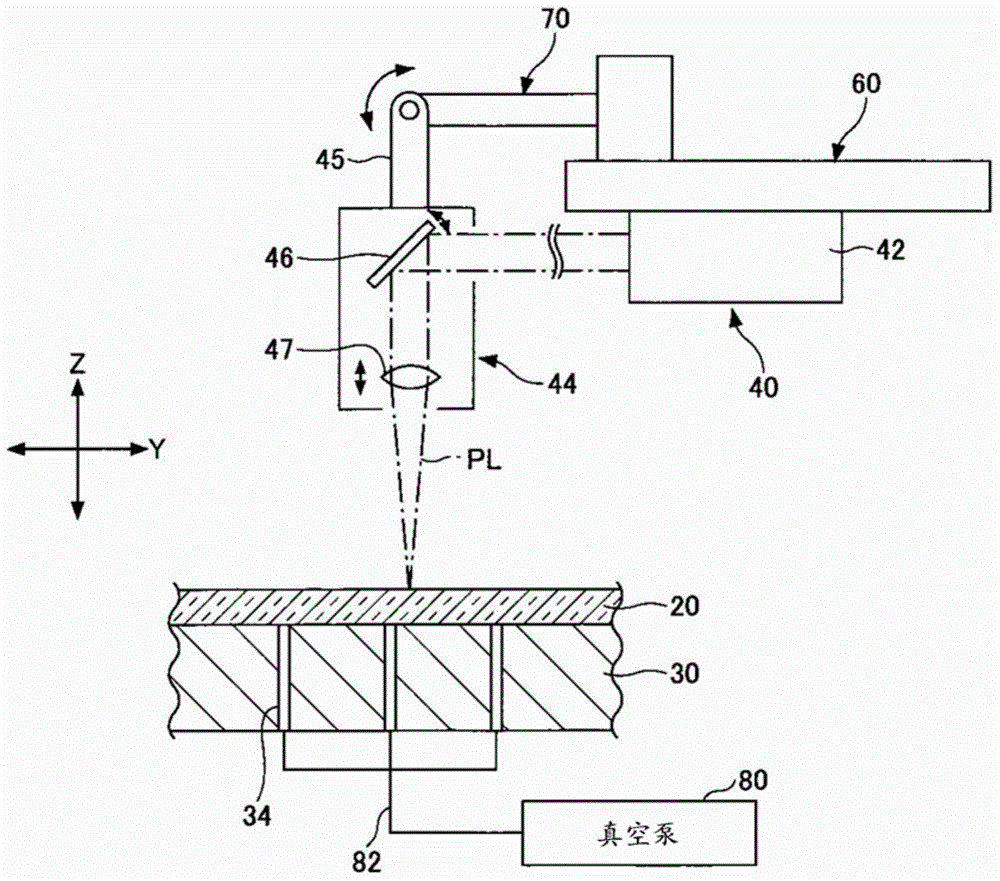

[0030] figure 1 It is a perspective view which shows the schematic structure of the laser processor which processes the disk-shaped glass substrate for magnetic recording media of this invention. Such as figure 1 As shown, the laser processor 10 has an X-Y table 30 loaded with a glass blank 20 , a laser generator 40 for irradiating a laser beam to the surface (upper surface) of the glass blank 20 , and a control unit 50 .

[0031] The glass blank 20 is, for example, a glass material formed into a plate shape by a float method, a melting method, a down-draw method, a re-stretching method, or a press molding method, and is cut in advance so that it can be placed on the placement surface of the X-Y stage 30. The size (dimensions in the X direction and Y direction). In addition, since the glass blank 20 has an area much la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com