Index locating device of full-automatic small diamond saw blade double-surface edging machine

A technology of double-sided sharpening and indexing positioning, which is applied in the direction of positioning devices, tool trimming of sawing machine devices, precision positioning equipment, etc., can solve the problems of low degree of automation, long cutting time, poor cutting quality, etc., and achieve automation The effect of high degree, long service life and precise indexing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

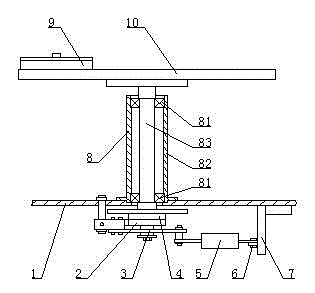

[0007] see figure 1 , the present invention includes a bottom plate 1, an indexing plate 2, an indexing linkage mechanism 3, a positioning plate 4, an indexing cylinder 5, a hinge 6, an indexing cylinder support 7, a main shaft assembly 8, a material receiving plate 9 and four stations The large turntable 10, the main shaft assembly 8 includes a shaft sleeve 82, a main shaft 83 and two bearings 81, the shaft sleeve 82 is mounted on the bottom plate 1 with screws, and the two bearings 81 are respectively installed in the inner parts of the two ends of the shaft sleeve 82 In the hole, the main shaft 83 is installed in the inner holes of the two bearings 81, the indexing cylinder support 7 is mounted on the bottom of the base plate 1 with bolts, and the indexing cylinder 5 is connected to the indexing cylinder support through the hinge 6 7 connection, the indexing link mechanism 3 is connected with the extension shaft of the indexing cylinder 5 through the rotating shaft, the ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com