Method for preparing super-hydrophobic self-lighting coating

A self-luminous coating and super-hydrophobic technology, which can be used in coatings, devices for coating liquids on surfaces, surface pretreatment, etc., can solve the problems that the preparation and performance of super-hydrophobic self-luminous coatings have not yet been reported in the literature. Achieve the effect of solving water decomposition or luminous intensity reduction, simple process and expanding application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 0.05g of a long-lasting luminescent body whose emission is blue (peak value is 456nm) to the mixture of 1g of PMMA high polymer monomer and initiator 2-hydroxyl-2-methyl-p-hydroxyethyl ether base phenylacetone (The ratio of monomer and initiator is 20:1), and add the cross-linking agent vinyltriethoxysilane (VTES) that mass content is 0.1%, keep stirring until the long afterglow luminous body and the monomer mix evenly, adopt The above mixture is dropped on a glass sheet by scraping method, and evenly coated with a coating machine, the coating speed is 99mm / s, and then irradiated with ultraviolet light in the wavelength range of 250-420nm for 1min, and the light intensity is 1mW, to obtain A 10 μm thick PMMA film doped with luminescent powder; then placed in a vacuum desiccator, dripping chlorosilane in an aqueous solution, and hydrolyzing and polycondensing chlorosilane to prepare a blue superhydrophobic luminescent coating, and water droplets on the coating The st...

Embodiment 2

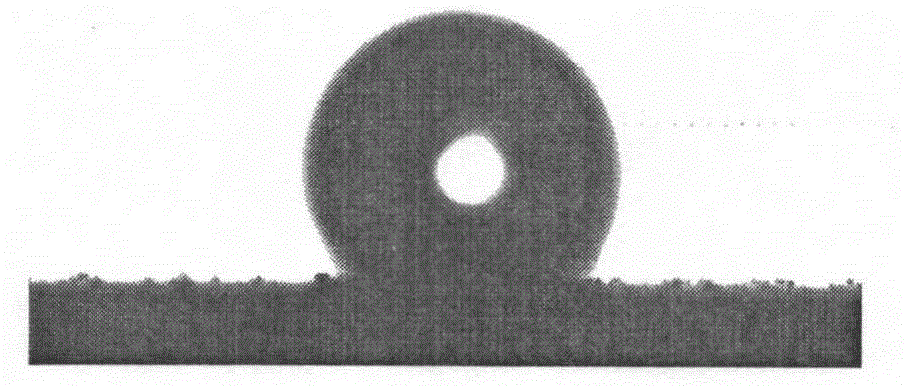

[0032] Add 2.5g of a long-lasting luminescent body whose emission is green (peak value is 510nm) into a mixture of 25g of PA high molecular polymer monomer and aqueous azo initiator azobisisobutylamidine hydrochloride (monomer and initiator The ratio of the agent is 10:1), and the cross-linking agent phenolic resin with a mass content of 1% is added, and the stirring is continued until the long-lasting luminous body is mixed evenly. Uniform coating with a coating speed of 1mm / s, and then placed at 120°C for 1h to dry to obtain a 1000μm thick PA film doped with a long-lasting luminous body; through the self-assembly of perfluorooctyltrichloromethylsilane , On this basis, a green superhydrophobic coating was prepared, and the static contact angle of water droplets on the coating was 155°-157°. as attached figure 1 As shown, the self-luminous coating prepared by the above method has a water drop contact angle of 157° as measured by the static contact angle.

Embodiment 3

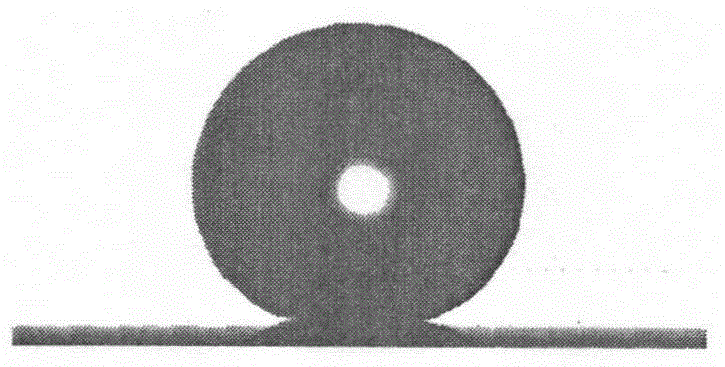

[0034] Add 3g of a long-lasting luminescent body that emits red light (peak at 780nm) into a mixture of 5g of PET monomer and initiator benzophenone (DP) (the ratio of monomer to initiator is 1:1), and add The cross-linking agent N, N'-methylenebisacrylamide with a mass content of 5%, and continuously stirred until the long-lasting luminous body is mixed evenly, and the above-mentioned mixture is dripped on the wood substrate by the spin coating method, and evenly mixed with a glue leveler. Spin coating, the spin coating speed is 1kr / min, and then irradiate with ultraviolet light in the wavelength range of 250-420nm for 5min, the light intensity is 2W, to obtain a PET film with a thickness of 100μm; then pass through the surface of octyltrimethoxysilane modification, successfully prepared a red super-hydrophobic surface, as shown in the attached figure 2 As shown, the self-luminous coating prepared by the above method has a water drop contact angle of 163° as measured by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emission wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Static contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com