Catalyst for preparing aromatics by use of methanol and preparation method of catalyst

A catalyst and aromatics technology, applied in the field of methanol to aromatics catalyst and its preparation, can solve the problems of low reaction activity and high yield of BTX, and achieve the effects of high reaction activity and high yield of aromatics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

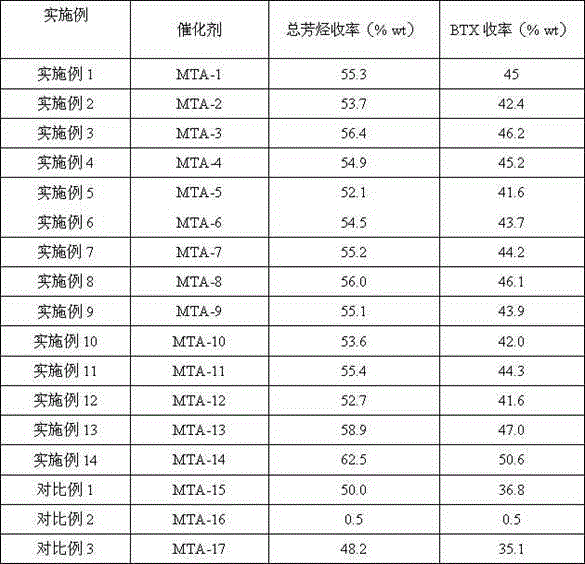

Examples

Embodiment 1

[0033] Weigh 90g of pseudo-boehmite and mix it with 600g of water, add 110g of orthophosphoric acid (85%) under stirring condition, continue stirring evenly, add 55g of silica sol (40%), 50g of triethylamine and 50g of tetraethyl hydroxide Ammonium, stir evenly; weigh 135g of H-type ZSM-5 molecular sieve, add it to the above mixed solution, and stir evenly; transfer the mixed solution to a closed high-pressure crystallization kettle, and crystallize at 180°C for 48h; after the product is taken out, pass Washing with water, drying, and roasting at 550°C for 4 hours to remove the template agent, to obtain the SAPO-34 / ZSM-5 composite molecular sieve, quantified by XRD diffraction, the weight content of the SAPO-34 molecular sieve in the product is 50%, and the weight content of the ZSM-5 molecular sieve is 50%. %.

[0034] Weigh 20g SAPO-34 / ZSM-5 composite molecular sieve, mix it with 20g pseudoboehmite and 1.0g scallop powder, add an appropriate amount of dilute nitric acid, kne...

Embodiment 2

[0037] Weigh 20g of the SAPO-34 / ZSM-5 composite molecular sieve prepared in Example 1, mix it with 20g of silica sol (40% wt) and 1.0g of soluble starch, knead it evenly, and shape it by extrusion. Calcined for 6h to obtain the catalyst precursor. Using the impregnation method, the catalyst precursor was impregnated with 3% Zn using zinc nitrate aqueous solution as the impregnation solution, and then dried and calcined at 550°C for 3 hours to obtain the methanol-to-aromatics catalyst MTA-2.

[0038] The reactivity evaluation of the catalyst adopts the method of Example 1, and the results are listed in Table 1.

Embodiment 3

[0040] Weigh 20g of the SAPO-34 / ZSM-5 composite molecular sieve prepared in Example 1, mix it with 15g of pseudoboehmite, 5g of fumed silica, and 1g of celadon powder, add an appropriate amount of dilute nitric acid, knead evenly and use The catalyst precursor was obtained by extrusion molding, drying and calcination at 560°C for 4 hours. Using the impregnation method, the catalyst precursor was impregnated with 3% Zn using zinc nitrate aqueous solution as the impregnation solution, and then dried and calcined at 550°C for 5 hours to obtain the methanol-to-aromatic catalyst MTA-3.

[0041] The reactivity evaluation of the catalyst adopts the method of Example 1, and the results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com