A kind of star-shaped carbon dioxide immobilization carrier and preparation method thereof and preparation method of separation membrane material

A carbon dioxide and immobilized carrier technology, applied in chemical instruments and methods, gas fuel, semi-permeable membrane separation, etc., can solve single problems, achieve good storage stability, high permeability selectivity, and stable polymerization reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

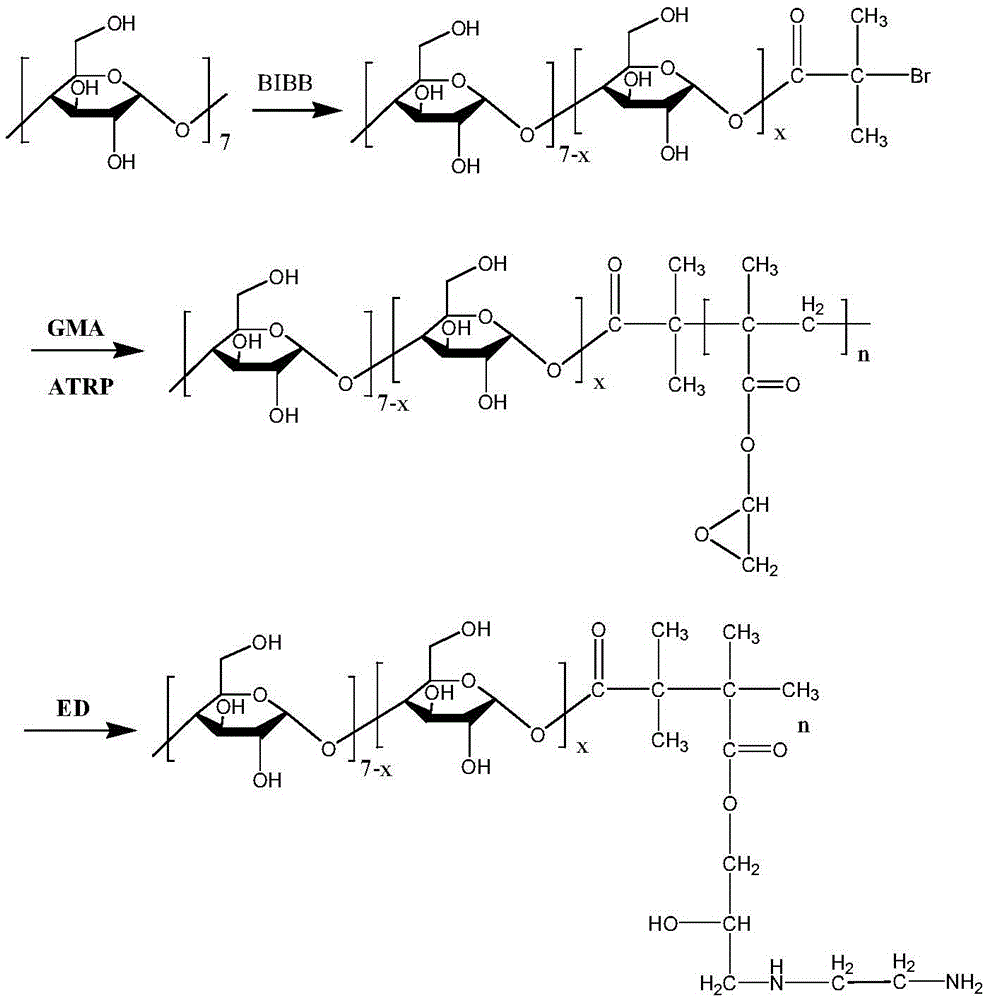

[0028] 1) Under anaerobic conditions, dissolve 0.1 part of cyclodextrin in 5 parts of DMF according to parts by weight, and add 0.2 part of BIBB (2-bromoisobutyryl bromide) under ice bath conditions, and the temperature of the reaction solution is 0 ℃, then add 0.4 parts of triethylamine, and react at 0-50℃ for 24 hours. After the reaction, the product is precipitated by adding ether until the shape becomes solid, washed with acetone, and placed in a vacuum drying oven to remove ether and acetone. The resulting product is the macroinitiator CD-Br.

[0029] 2) 0-50°C, under anaerobic conditions, first dissolve 0.2 parts of CD-Br in 5 parts of DMF, then add 3 parts of GMA (glycidyl methacrylate) as a monomer, and then add 0.082 parts of ligand N, N,N,N,N-Pentamethyldiethylenetriamine, finally add 0.033 parts of CuBr initiator, polymerize for 1 hour, expose to the air after the reaction, deactivate the initiator system and terminate the polymerization, then add Methanol was prec...

Embodiment 2

[0036] 1) Under anaerobic conditions, dissolve 0.2 parts of cyclodextrin in 10 parts of DMF according to parts by weight, and add 0.6 parts of BIBB under ice bath conditions. At this time, the temperature of the reaction solution is controlled at 0°C, and then add 0.6 parts of triethylamine Amine, react at 0-50°C for 24 hours. After the reaction, the product is precipitated by adding ether until the shape becomes solid, washed with acetone, and put in a vacuum drying oven to remove ether and acetone. The obtained product is a macromolecular initiator CD- Br.

[0037] 2) 0-50°C, under anaerobic conditions, first dissolve 0.5 parts of CD-Br in 10 parts of DMF, then add 6 parts of GMA as a monomer, and then add 0.15 parts of ligand 2,2-bipyridine (BPY), Finally add 0.1 part of CuBr initiator, polymerize for 8 hours, expose to the air after the reaction, deactivate the initiator system and terminate the polymerization, then add methanol to precipitate until the shape becomes solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com