Preparation method of bezoar detoxifying film coated tablet

A film coating and bezoar detoxification technology, which is applied to medical preparations containing active ingredients, anti-toxins, and pharmaceutical formulas, can solve the problems of splits, thick coating layers, and high labor intensity, so as to reduce fiber elasticity and increase fiber elasticity. Adhesive, uniform surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

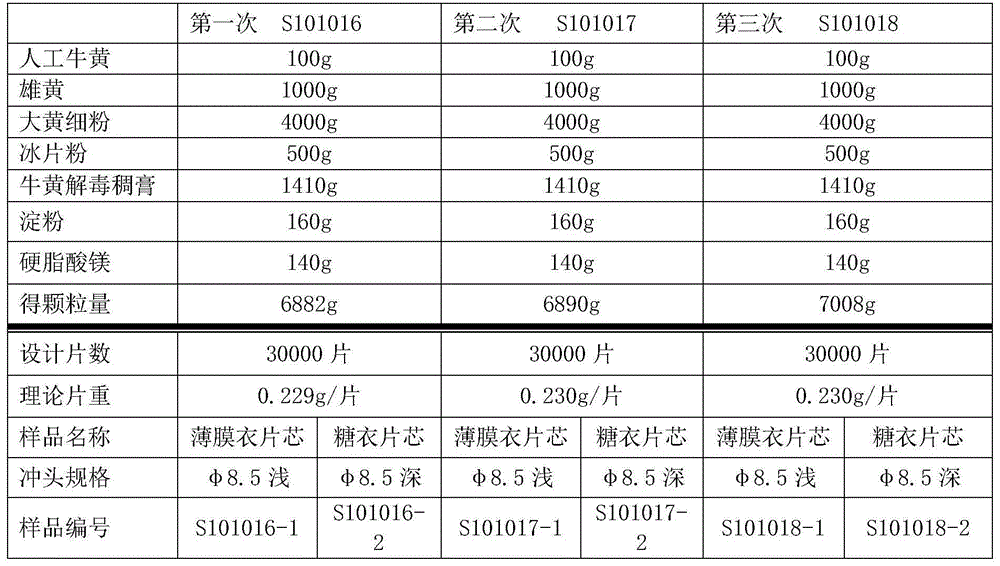

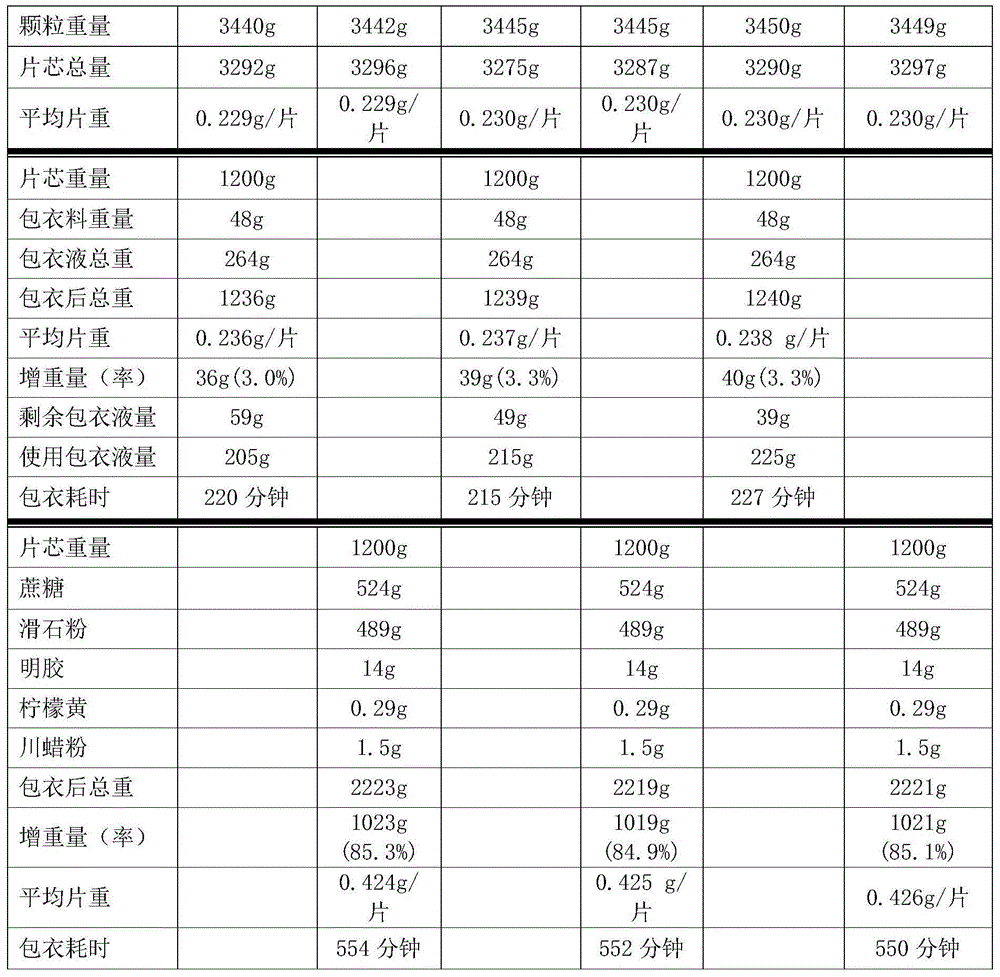

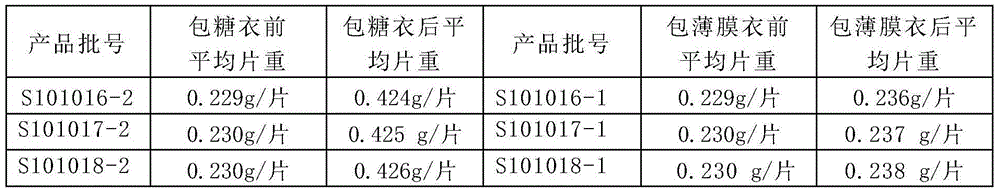

[0024] A kind of preparation method of Niuhuangjiedu film-coated tablet:

[0025] 1) Raw material processing: Take 5g of artificial bezoar, 50g of realgar, 200g of gypsum, 200g of rhubarb, 50g of skullcap, 100g of bellflower, 25g of borneol, 50g of licorice, fly realgar into fine powder, crush rhubarb into fine powder, grind artificial bezoar and borneol fine; the other four flavors of Scutellaria baicalensis and other four flavors are decocted twice with water, 2 hours each time, the decoctions are combined, filtered, and the filtrate is concentrated into a thick paste with a relative density of 1.20 (70°C);

[0026] 2) Tablet compression: add rhubarb, realgar powder, and 8 g of auxiliary material starch to make granules, dry, then add artificial bezoar and borneol powder, mix well, and compress into 1,500 plain tablets (small pieces);

[0027] 3) Coating: Put the plain tablets into the coating pot, use the rolling coating method, spray the coating solution with a sprayer, ke...

Embodiment 2

[0034] A kind of preparation method of Niuhuangjiedu film-coated tablet:

[0035] 1) Raw material processing: Take 5g of artificial bezoar, 50g of realgar, 200g of gypsum, 200g of rhubarb, 50g of skullcap, 100g of bellflower, 25g of borneol, 50g of licorice, fly realgar into fine powder, crush rhubarb into fine powder, grind artificial bezoar and borneol fine; the other four flavors of Scutellaria baicalensis and others are decocted twice with water, 2 hours each time, combined with the decoction, filtered, and the filtrate is concentrated into a thick paste with a relative density of 1.25 (70°C);

[0036] 2) Tablet compression: add rhubarb, realgar powder, and 8 g of auxiliary material starch to make granules, dry, then add artificial bezoar and borneol powder, mix well, and compress into 1,500 plain tablets (small pieces);

[0037] 3) Coating: Put the plain tablets into the coating pot, use the rolling coating method, spray the coating liquid with a sprayer, keep the tempera...

Embodiment 3

[0044] A kind of preparation method of Niuhuangjiedu film-coated tablet:

[0045] 1) Raw material processing: Take 5g of artificial bezoar, 50g of realgar, 200g of gypsum, 200g of rhubarb, 50g of skullcap, 100g of bellflower, 25g of borneol, 50g of licorice, fly realgar into fine powder, crush rhubarb into fine powder, grind artificial bezoar and borneol fine; add water and decoct the other four flavors such as Scutellaria baicalensis twice, each time for 2 hours, combine the decoction, filter, and concentrate the filtrate into a thick paste with a relative density of 1.22 (70°C);

[0046] 2) Tablet compression: add rhubarb, realgar powder, and 8 g of auxiliary material starch to make granules, dry, then add artificial bezoar and borneol powder, mix well, and compress into 1,500 plain tablets (small pieces);

[0047] 3) Coating: Put the plain tablets into the coating pot, use the rolling coating method, spray the coating solution with a sprayer, keep the temperature in the pot a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com