Compound type polyurethane toilet seat and preparation technology thereof

A preparation process and polyurethane technology, applied in the field of sanitary ware, can solve the problems of unsightly product appearance, easy peeling time, increase processing cost, etc., achieve simple and convenient processing process, improve use quality and comfort, save secondary The effect of the molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

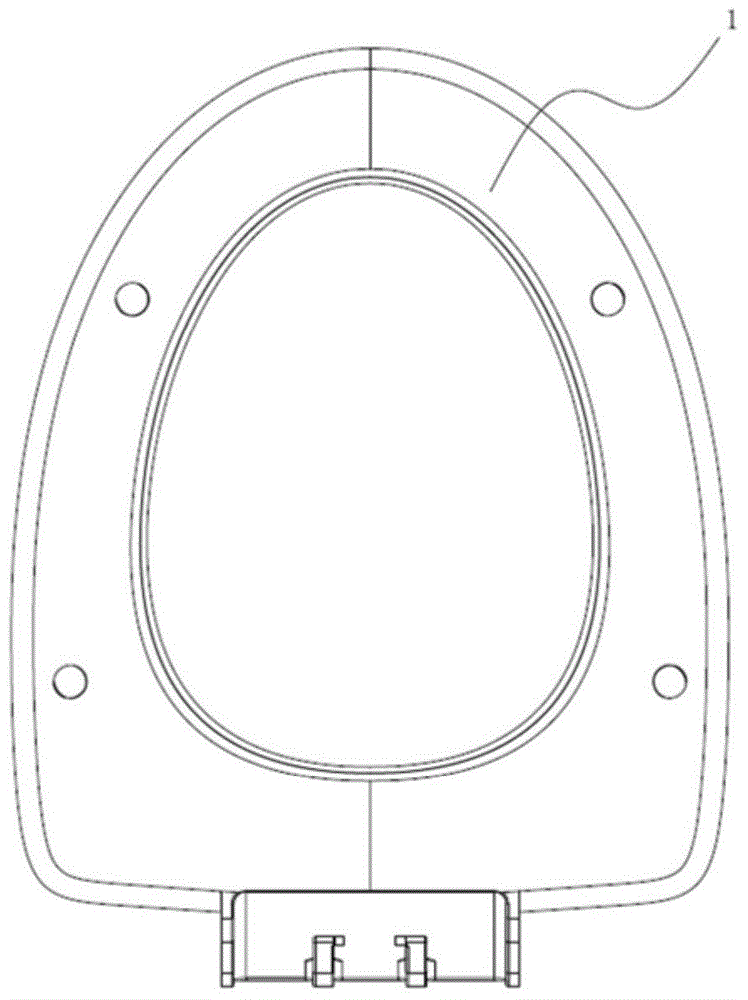

Image

Examples

Embodiment 1

[0053] Component A and component B were reacted at a temperature of 30° C. to obtain the polyurethane of this embodiment. Among them, component A is prepared from the following raw materials in parts by weight: 100 parts of polyether polyol (70 parts of polyether polyol (Mn=5000), 30 parts of polymer polyol), 5 parts of chain extender (B 3.5 parts of diol, 2 parts of 1,4 butanediol), 1.2 parts of catalyst (1.2 parts of amine catalyst), 0.75 parts of surfactant (0.75 parts of silane surfactant), 15 parts of blowing agent (one fluoro di Chloroethane HCFC-141b 15 parts); B component is isocyanate, and the mass ratio of B component / A component is 0.35.

[0054] The technology for preparing composite polyurethane toilet seat cushion comprises the following steps:

[0055] Step 1, spraying a layer of release agent and a layer of in-mold paint successively in the cavity of mold 3;

[0056] Step 2, use industrial alcohol to clean the surface of cushion bracket 2;

[0057] Step 3, p...

Embodiment 2

[0066] Component A and component B were reacted at a temperature of 40° C. to obtain the polyurethane of this embodiment. Among them, component A is prepared from the following raw materials in parts by weight: 100 parts of polyether polyol (80 parts of polyether polyol (Mn=5000), 20 parts of polymer polyol), 3 parts of ethylene glycol, 1 , 2 parts of 4 butanediol, 2 parts of amine catalyst, 0.5 part of surfactant, 20 parts of blowing agent; B component is isocyanate, and the mass ratio of B component / A component is 0.25.

[0067] The technology for preparing composite polyurethane toilet seat cushion comprises the following steps:

[0068] Step 1, spraying a layer of release agent and a layer of in-mold paint successively in the cavity of mold 3;

[0069] Step 2, use industrial alcohol to clean the surface of cushion bracket 2;

[0070] Step 3, polishing or sandblasting the cushion support 2, and blowing the dust on the surface of the treated cushion support 2;

[0071] St...

Embodiment 3

[0079] Component A and component B were reacted at a temperature of 20° C. to obtain the polyurethane of this embodiment. Among them, component A is prepared from the following raw materials in parts by weight: 100 parts of polyether polyol, 3.5 parts of ethylene glycol, 1.5 parts of 1,4 butanediol, 0.8 parts of amine catalyst, 0.75 parts of silane surfactant Parts, 12 parts of fluorodichloroethane HCFC-141b; component B is isocyanate, and the mass ratio of B / A is 0.55.

[0080] The technology for preparing composite polyurethane toilet seat cushion comprises the following steps:

[0081] Step 1, spraying a layer of release agent and a layer of in-mold paint successively in the cavity of mold 3;

[0082] Step 2, use industrial alcohol to clean the surface of cushion bracket 2;

[0083] Step 3, polishing or sandblasting the cushion support 2, and blowing the dust on the surface of the treated cushion support 2;

[0084] Step 4, heat-treat the cleaned cushion bracket 2 at a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com