Composite strap for underwear, production technology and specialized setting and positioning machine

A production process and locator technology, applied to shoulder straps, tools for sewing clothes, corsets, etc., can solve the problems of poor durability of shoulder straps, poor durability, thick sewing parts, etc., and achieve the goal of shoulder straps Moderate thickness, avoiding cervical spine strain, and relieving pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

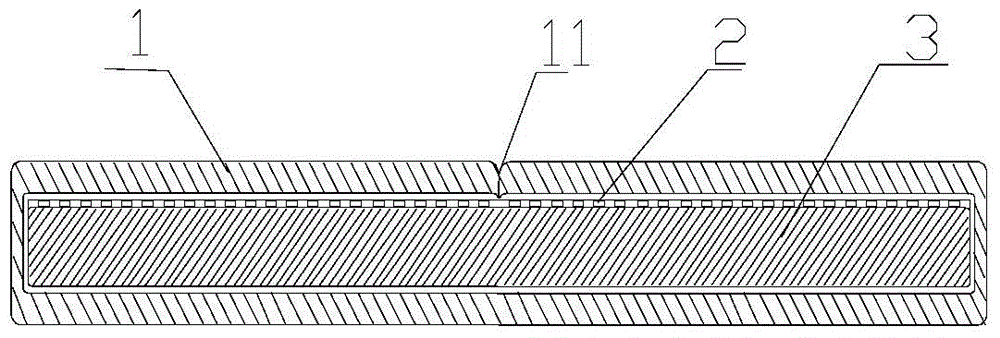

[0021] Attached below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , the present invention is further described:

[0022] The present invention adopts a multi-layer composite structure in order to make the shoulder strap have good elasticity, breathability, and durability. The outermost layer is made of chemical fiber bundles, because the chemical fiber has hot-melt properties, and can be fused by using thermal cutting technology while cutting. The outer chemical fiber bundle 1 is wrapped on the outer surface of the elastic webbing 3; the adhesive layer 2 is placed between the inner surface of the outer chemical fiber bundle 1 and the outer surface of the elastic webbing 3; the outer layer The two butt edges of the chemical fiber cloth 1 are seamlessly connected. The use of double-sided adhesive tape to connect the elastic webbing can not only ensure the firmness of the bonding, but also ensure that the bonding has a certain degree of air permea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com