Thermosetting foam with improved thermal insulation and flame retardancy, and preparation method therefor

A technology of thermosetting and foaming body, applied in the field of thermosetting foaming agent and its preparation, can solve the problems of reduction of physical properties and thermal insulation performance of thermosetting foaming body, achieve low thermal conductivity, outstanding flame retardant sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] Method for preparing thermosetting foam

[0055] Yet another example of the present invention provides a method for preparing a thermosetting foam, the method for preparing the above thermosetting foam includes: a step of mixing a polyol compound and a nucleating agent, the polyol compound and the nucleating agent The step of adding a flame retardant to the mixture, and the step of stirring isocyanate compounds in the mixture obtained after adding the above flame retardant to polymerize polyisocyanurate; the starting temperature according to the thermogravimetric analysis method is 310°C above. The thermal decomposition onset temperature may be above about 310° C., which is as described above.

[0056] The speed of mixing the polyol compound and the nucleating agent in the step of mixing the polyol compound and the nucleating agent may be about 500 rpm to about 5000 rpm. For the uniform dispersion of polyol compounds and nucleating agents, mix at a low speed of about ...

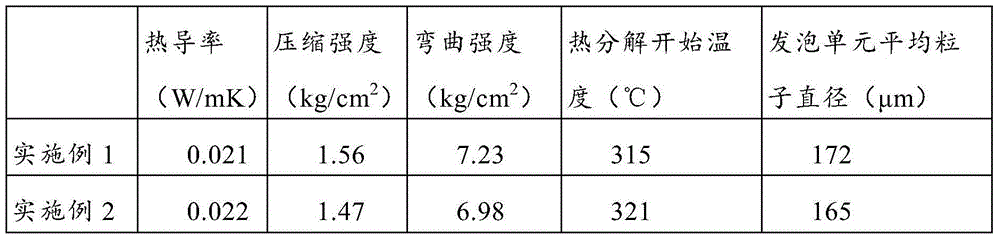

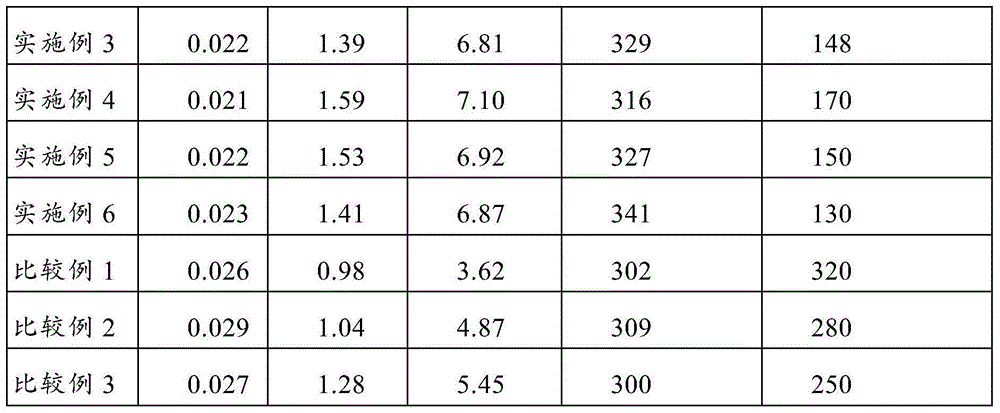

Embodiment 1

[0065] 3.0 g of tetramethylsilane (TMS, Tetramethyl silane) as a nucleating agent and 1.0 g of cumyl diphenyl phosphate (IPPP, IsoPropylPhenyl Diphenyl Phosphate) as a flame retardant were added to 100 g of polyol by weight. A mixture of polyether polyol and polyester polyol was mixed at a weight ratio of 4:6 and used as the polyol. Compared with the tetramethylsilane used as a nucleating agent, the viscosity of the polyol used is high. Therefore, in order to allow the tetramethylsilane to be well inserted between the polyol compounds, a mechanical stirrer (mechanical stirrer) is used. In the early stage of the reaction, stir at a low speed of 500rpm for 30 seconds (stirring in the first step), and then stir respectively at speeds of 1000rpm, 2000rpm, 3000rpm, 4000rpm, and 5000rpm (stirring in the second step) for 30 seconds to prepare a mixed solution.

[0066] Add 1.0 g of cumyl diphenyl phosphate (IPPP, IsoPropylPhenyl Diphenyl Phosphate) as a flame retardant to the above m...

Embodiment 2

[0068] A thermosetting foam was prepared in the same manner as in Example 1 above, except that the amount of cumyl diphenyl phosphate (IPPP, IsoPropylPhenyl Diphenyl Phosphate) as a flame retardant was increased to 3.0 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle diameter | aaaaa | aaaaa |

| Average particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com