Manufacturing method for resin plug hole in PCB

A production method and technology of resin plugging holes, which are applied in the direction of printed circuit manufacturing, processing step sequence, electrical components, etc., can solve the problems of shortening the process flow, affecting the production accuracy of the subsequent process, and board expansion and contraction, so as to shorten the production process and ensure The effect of manufacturing precision and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

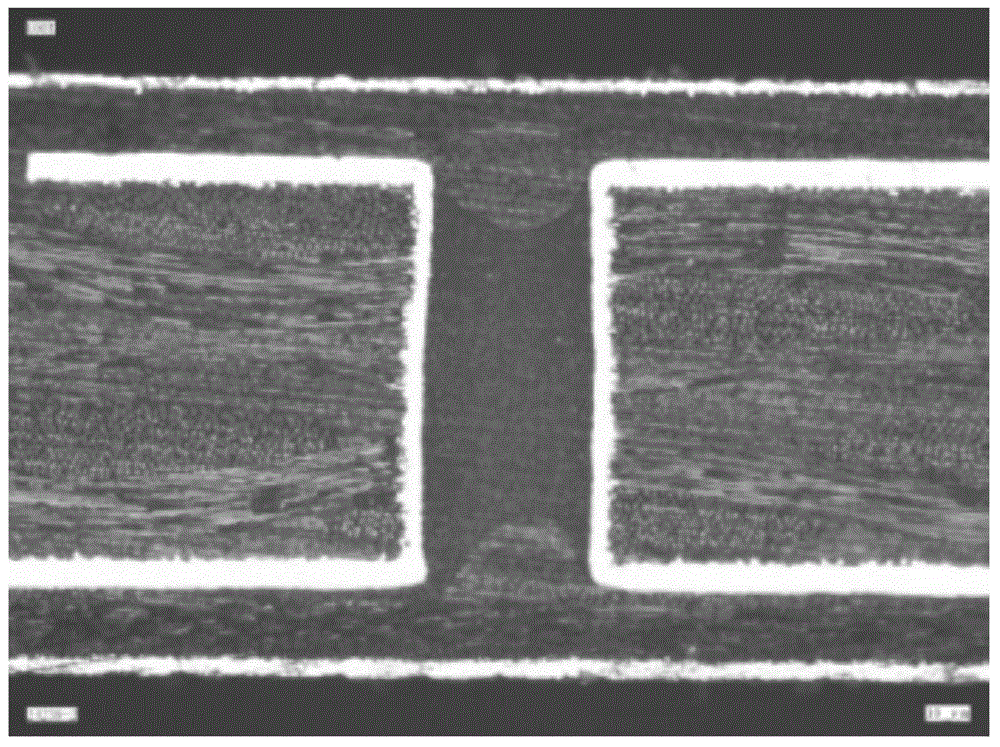

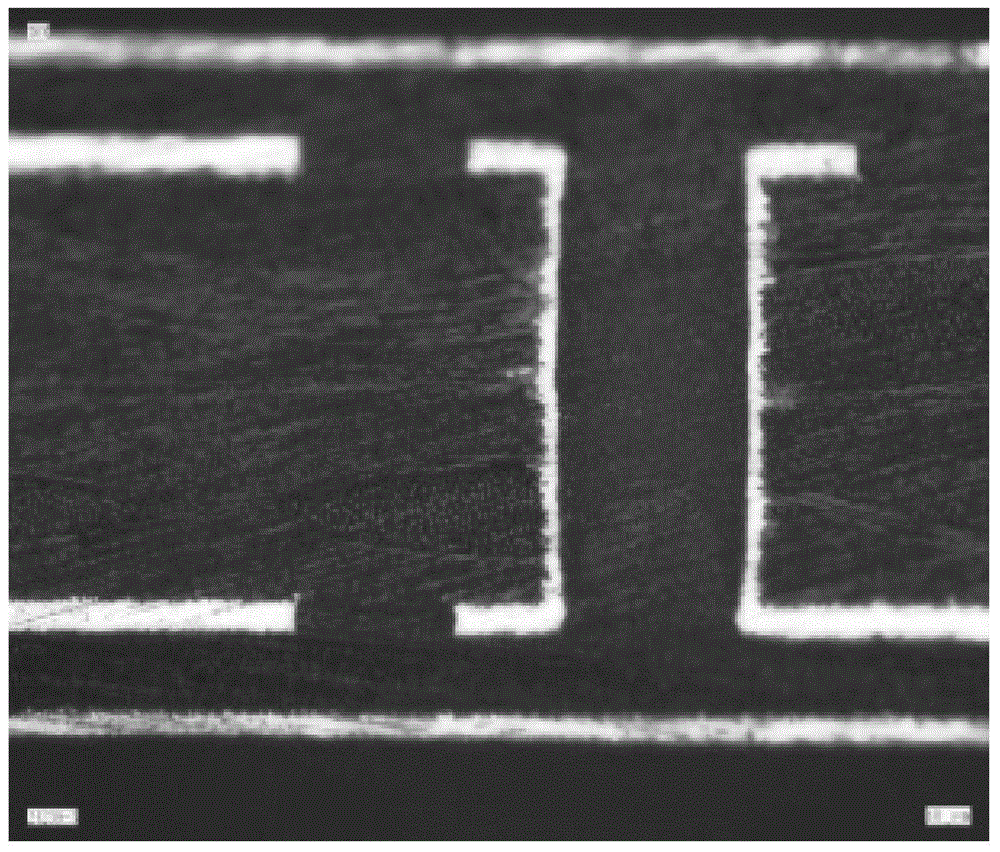

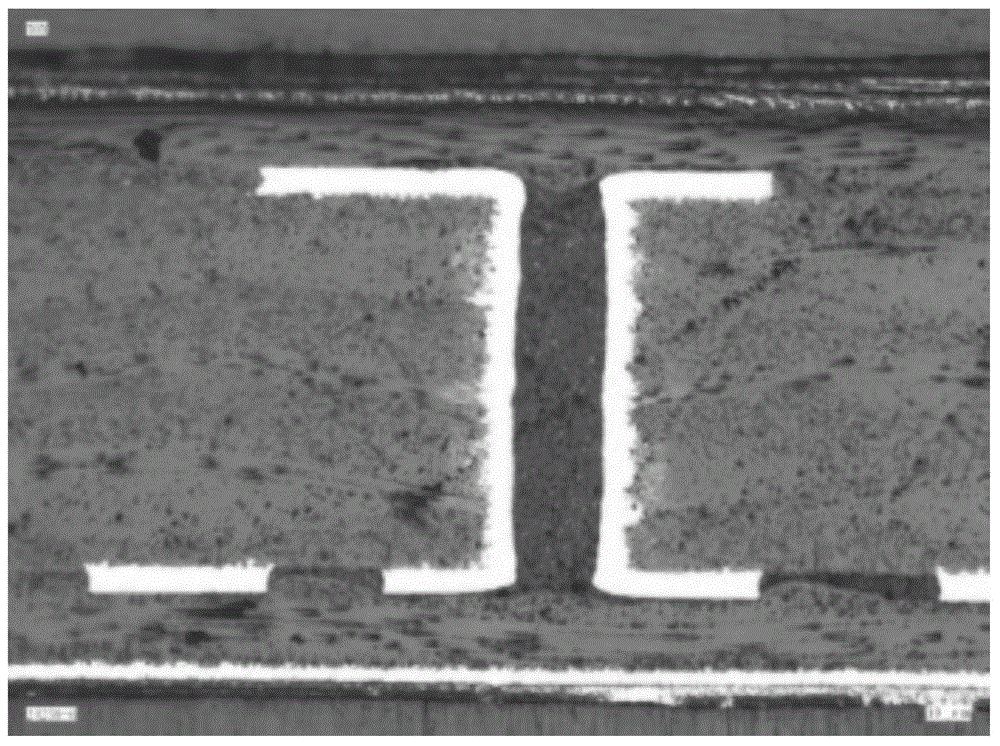

Image

Examples

Embodiment

[0019] This embodiment provides a method for manufacturing a resin plug hole in a PCB. The parameters of the PCB manufactured by this method are as follows:

[0020]

[0021] The specific production steps are as follows:

[0022] (1) First cut the base material, the thickness of the core board is 1.2mm H / H, and then use the drilling data to drill holes that need to be made into metallized buried holes on the core board. Then, the core board is sequentially subjected to copper sinking treatment (backlight test level 10) and full board electroplating treatment (full board electroplating at a current density of 18ASF for 60 minutes, and the thickness of the hole copper is Min 20 μm), so that the drilled holes are metallized to form metallization buried hole.

[0023] (2) Use the negative film process (or positive film process) to make the inner layer circuit on the core board. When making the inner layer circuit, use a fully automatic exposure machine to complete the inner la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com