Battery pack heating device

A technology for heating devices and battery packs, applied to secondary batteries, circuits, electrical components, etc., can solve the problems of large space occupation, high safety risks, and high safety risks of heating wires, so as to achieve small space, reduce safety risks, and ensure Effect of Temperature Range and Temperature Consistency Used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

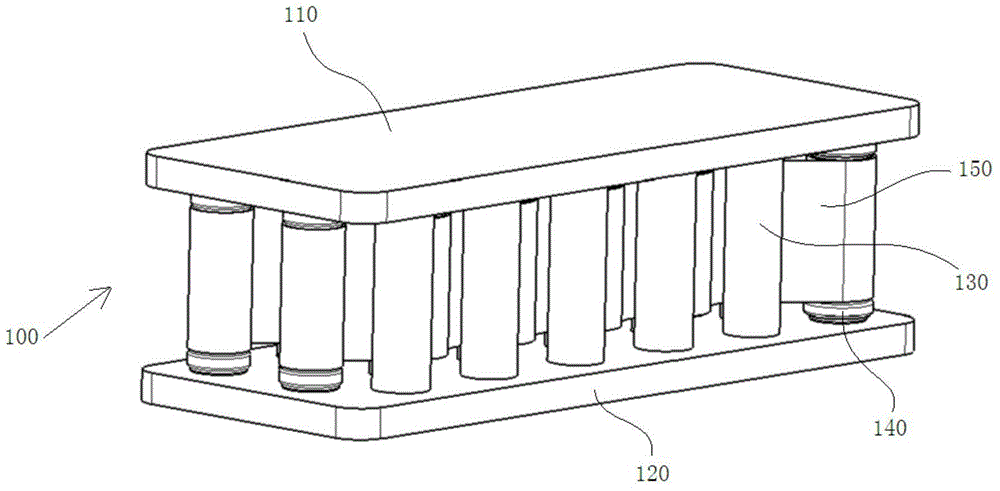

[0029] refer to figure 1 , the battery pack heating device 100 includes an upper support plate 110 , a lower support plate 120 , a battery cell 130 , a PTC heating column 140 and a heat conduction plate 150 .

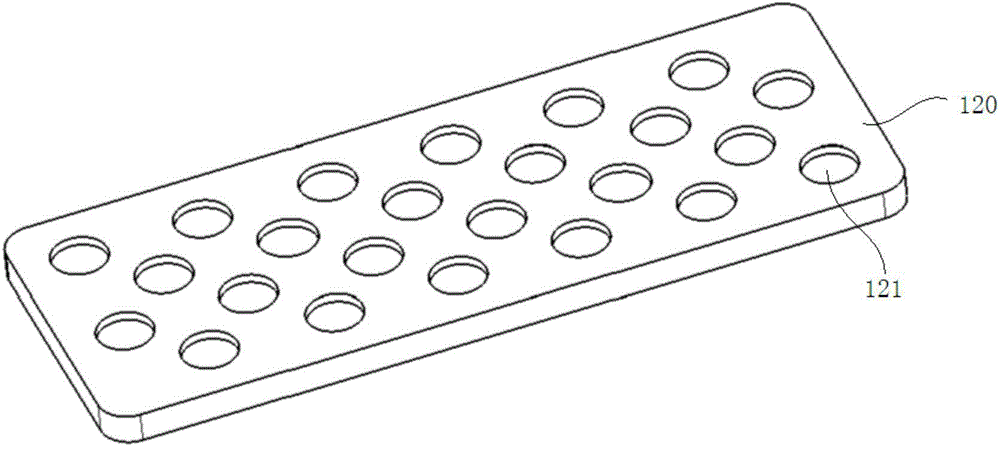

[0030] refer to figure 2 , the lower support plate 120 is provided with a plurality of rows of positioning holes 121 . The structure of the upper support plate 110 is the same as that of the lower support plate 120, and will not be described in detail herein.

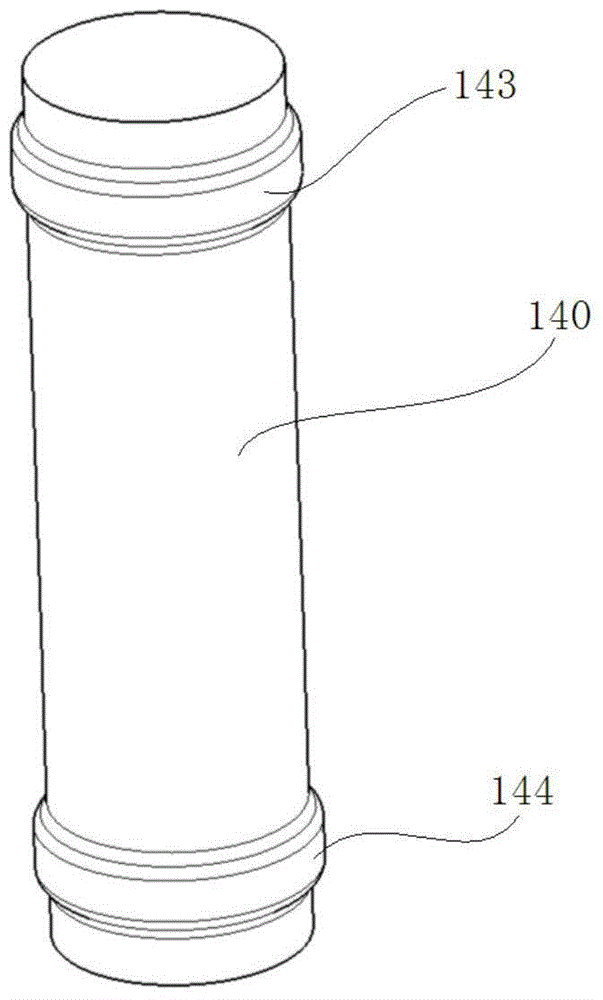

[0031] refer to image 3 , the PTC heating column 140 is made of PTC material into a column shape, and the PTC heating column 130 has an upper flange 143 and a lower flange 144 .

[0032] refer to Figure 4 , the heat conduction plate 150 is made of aluminum plate or other high heat conduction material, and is bent into a wavy shape with troughs 151 and crests 152 . The cylindrical part 153 is wound around both ends of the heat conduction plate 150 .

[0033] refer to Figure 5 , each heat conducting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com