Simple preparation method of graphite and/or silicon negative electrode material with surface coated with carbon

A silicon negative electrode, carbon coating technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of high production cost, cumbersome process, high operation cost, and achieve simple coating method, uniform coating layer, and easy operation. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

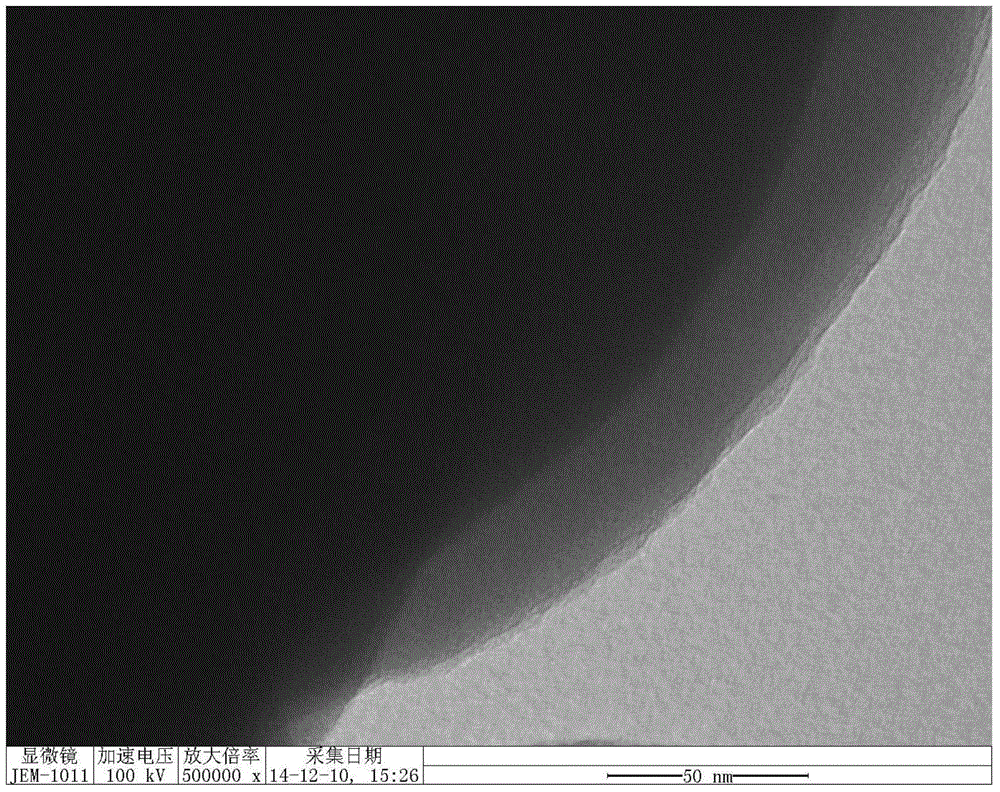

[0021] First, in a 500ml beaker, dissolve 0.03g of dopamine hydrochloride in 450ml of water, then add 1g of tris / tris hydrochloride Tris mixture (solution pH is 7), stir for 5min, Add 3 g of graphite after dissolution. Then put the beaker into a constant temperature water bath, set the reaction temperature at 1°C, stir mechanically for 24 hours, and rotate at a speed of 80r / min. After the reaction time has elapsed, filter, wash with deionized water three times, and then dry overnight in an oven at 50°C to obtain polydopamine-coated spherical graphite. Afterwards, under the protection of nitrogen atmosphere, it was carbonized in a tube furnace at 200° C. for 2 hours to obtain modified spherical graphite uniformly coated with an amorphous carbon layer. Therefore, the carbon coating thickness of graphite coated graphite using dopamine as a carbon precursor can reach 20-30nm, see figure 1 . It can be seen from the figure that the coating is very uniform.

Embodiment 2

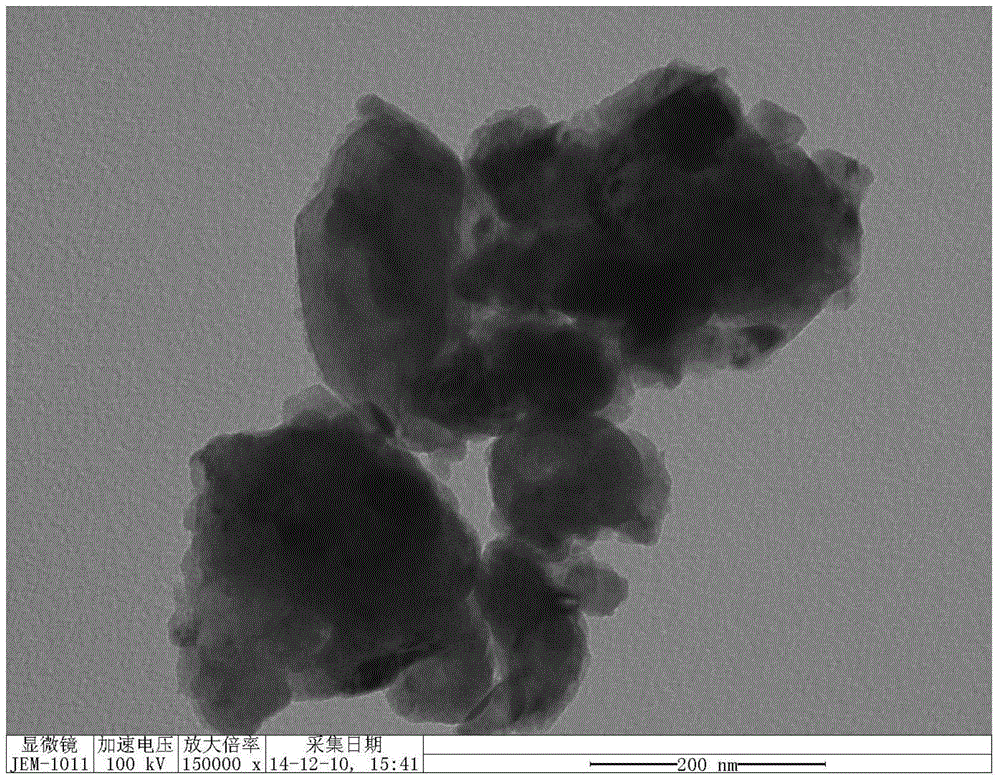

[0023] First, in a 500ml beaker, dissolve 50g of dopamine hydrochloride in 450ml of water, then add 20g of Tris (the pH of the solution is 15), stir for 5min, and add 10g of silicon after dissolving. Then put the beaker into a constant temperature water bath, set the reaction temperature to 100°C, stir mechanically for 0.5h, and rotate at a speed of 80r / min. After the reaction time has elapsed, filter, wash with deionized water three times, and then dry overnight in an oven at 70°C to obtain polydopamine-coated spherical graphite. Afterwards, under the protection of argon atmosphere, it was carbonized in a tube furnace at 1500° C. for 2 hours to obtain a modified spherical graphite uniformly coated with an amorphous carbon layer. Therefore, the carbon coating layer thickness of silicon coated with dopamine as carbon precursor can reach 10-20nm, see figure 2 . The graphite, as a lithium battery anode material, has an efficiency as high as 95% in the first week, and a capacit...

Embodiment 3

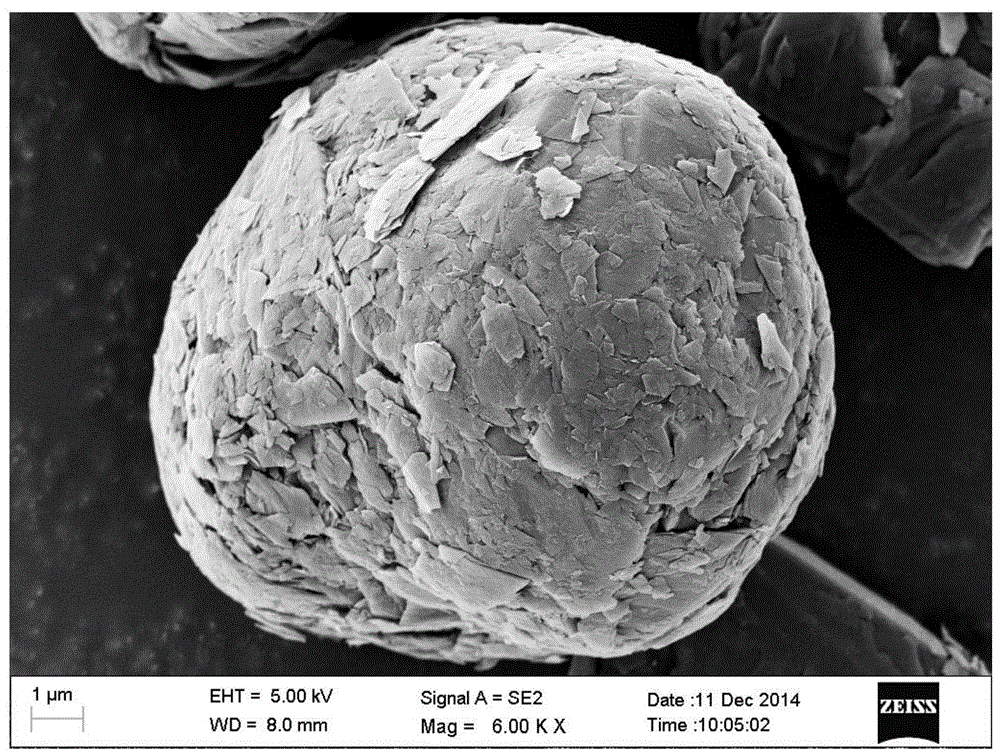

[0025] First, in a 500ml beaker, dissolve 20g of dopamine hydrochloride in 400ml of water, then add 1.35g of Tris (the pH of the solution is 8.5), stir for 5min, and add 1g of graphite after dissolving. Then put the beaker into a constant temperature water bath, set the reaction temperature to 50°C, stir mechanically for 48 hours, and rotate at a speed of 80r / min. After the reaction time has elapsed, filter, wash with deionized water three times, and then dry overnight in an oven at 50°C to obtain polydopamine-coated spherical graphite. Afterwards, under the protection of nitrogen atmosphere, it was carbonized in a tube furnace at 1000° C. for 4 hours to obtain a modified spherical graphite uniformly coated with an amorphous carbon layer. According to the comparison of the SEM pictures before and after spherical graphite coating, the graphite surface is obviously covered by the coating layer. For details, see image 3 and Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com