Nitrite-free concentrated solution for rapidly biodegrading mine prop and preparation method

A biodegradation and nitrite technology, applied in the field of application and maintenance of mining machinery, can solve the problems of reducing anti-rust performance and groundwater pollution, and achieve the effect of excellent lubricating performance and good lubricating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the antirust agent package is as follows: fully mix the organic acid and the alcohol amine compound in a suitable container and heat it to 145-160° C., maintain the temperature condition and fully stir the reaction for 1.5 to 2.0 hours to carry out the amidation reaction.

[0030] The preparation method of the nitrite-free rapid biodegradable mine support concentrate of the present invention comprises the steps of: adding part of soft water to the prepared antirust agent package, so that the antirust agent package and soft water are evenly mixed to obtain a homogeneous antirust agent Rust agent package solution, and cooled to 50±5°C, add benzotriazole as a non-ferrous metal anti-corrosion agent into the rust preventive package solution, stir fully to dissolve the benzotriazole solid in the rust preventive package solution; Then add successively C16-C18 unsaturated alcohol polyoxyethylene ether carboxylic acid as ionic surfactant, isotridecanyl p...

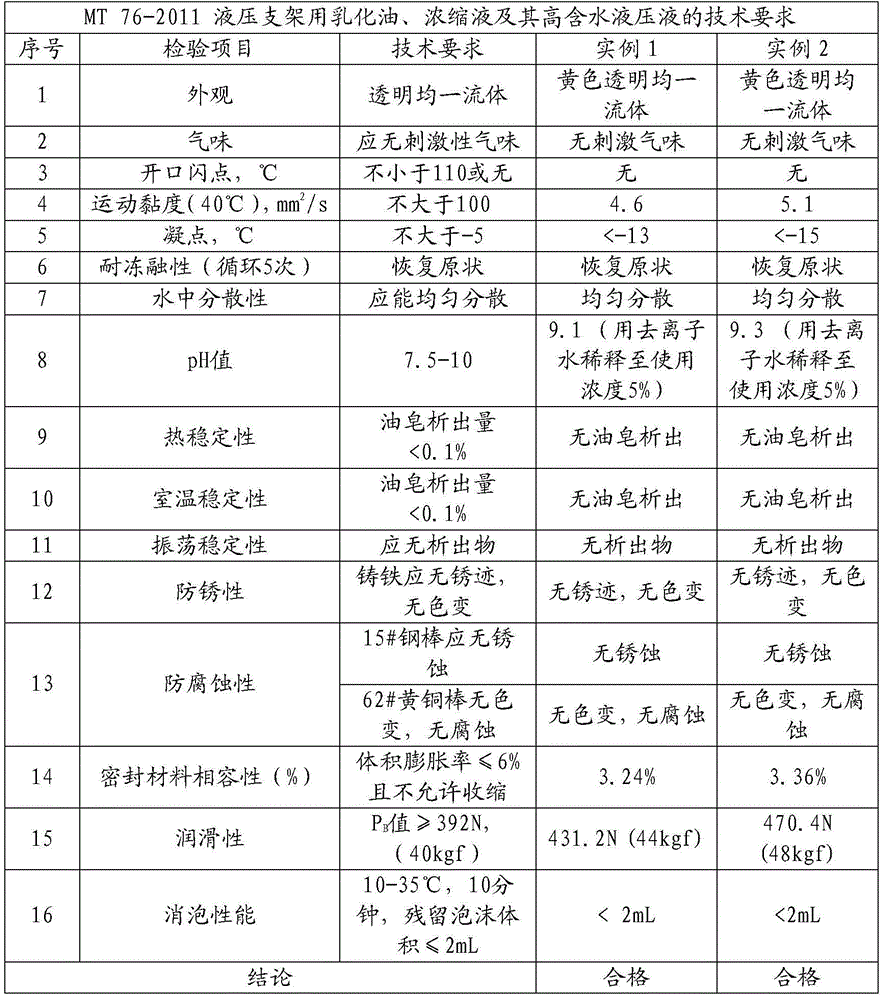

Embodiment 1

[0032] Embodiment 1: Concentrate solution for quick biodegradable mine support without nitrite, in terms of mass percentage, the concentrate solution consists of the following components:

[0033] Anti-rust agent package: n-capric acid 5%, sebacic acid 2%, oleic acid 2%, 21 carbon dimer acid 2%, monoethanolamine 3.5%, diethanolamine 2.5%, monoisopropanolamine 2%, Diethylene glycol amine 2%;

[0034] Other additive components: benzotriazole 0.5%, C16-C18 unsaturated alcohol polyoxyethylene ether carboxylic acid 0.5%, isotridecanyl polyoxyethylene ether 0.8%, polyoxypropylene polyoxyethylene copolymer 3%, Organic modified siloxane 0.1%, the balance is soft water. The polyoxypropylene-polyoxyethylene copolymer has a weight-average molecular weight of 80,000-120,000, and can be a linear random copolymer, a block copolymer or an alternating copolymer. This type of polymer polyether additive has multiple coordinated oxygen atoms, which can be more effectively combined with the met...

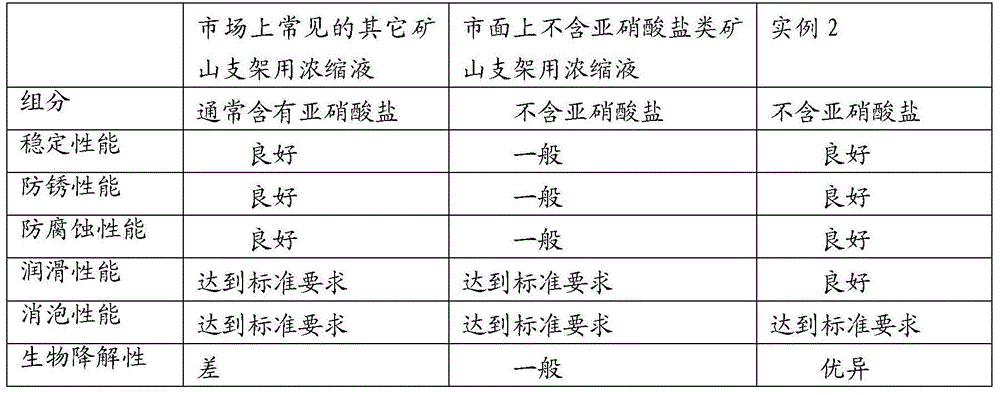

Embodiment 2

[0037] Embodiment 2: Concentrate solution for quick biodegradable mine support without nitrite, by mass percentage, the concentrate solution consists of the following components:

[0038] Antirust agent package: n-octanoic acid 6%, n-dodecanedioic acid 2%, oleic acid 2%, 21 carbon dimer acid 2%, monoethanolamine 4.5%, diethanolamine 3%, monoisopropanolamine 2 %, diglycolamine 2%;

[0039] Other additive components: benzotriazole 0.5%, C16-C18 unsaturated alcohol polyoxyethylene ether carboxylic acid 0.5%, isotridecanyl polyoxyethylene ether 0.9%, polyoxypropylene polyoxyethylene copolymer 5%, Organic modified siloxane 0.12%, the balance is soft water. The polyoxypropylene-polyoxyethylene copolymer has a weight-average molecular weight of 80,000-120,000, and can be a linear random copolymer, a block copolymer or an alternating copolymer.

[0040] All chemical additives in this example are commercially available.

[0041] The specific steps of the preparation method are as fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com