Tar slag machining process and system

A processing system and technology for tar residues, which are applied in the petroleum industry, coke ovens, processing tar pitch/petroleum pitch/natural pitch by distillation, etc., can solve the problems of insufficient storage capacity, unstable coke quality, secondary pollution, etc. The effect of good industrial application prospect, easy realization of process conditions and safe production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

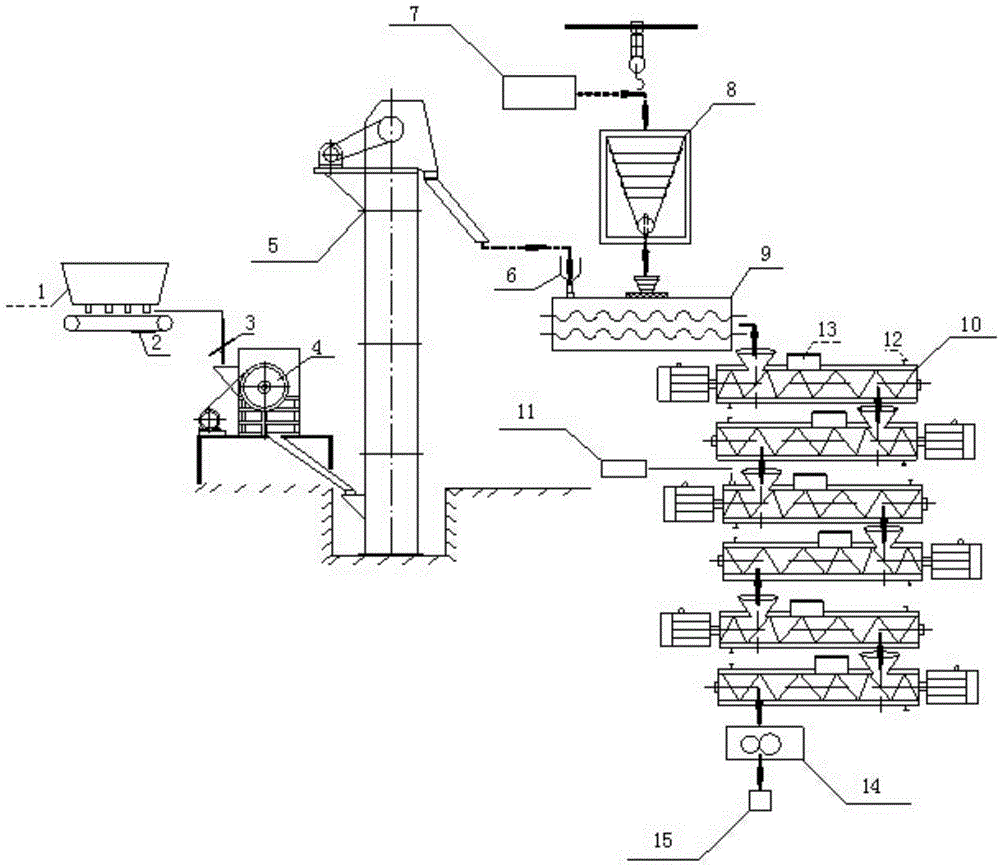

[0024] Embodiment 1: The process of clean processing and utilization of tar residue is as follows:

[0025] A) The broken coal in the coal feeding tank 1 is measured by the electronic scale 2 and then enters the crusher 4 to be crushed to less than 3mm and sent to the bucket elevator 5, and the bucket elevator 5 sends the fine coal into the double helix through the hopper 6 Mixer 9;

[0026] B) The tar residue is transported from the tar residue transfer box 7 to the twin-screw mixer 9 through the electric hoist 8; the tar residue and fine-grained coal are fully mixed in the twin-screw mixer;

[0027] C) The tar residue and fine-grained coal mixture in the double-screw mixer 9 are transported to the 6-stage spiral retort and conveying integrated machine to remove volatile matter, and the required temperature of the 6-stage spiral retort and conveying integrated machine is maintained by circulating heat transfer oil, The tar gas produced during the dry distillation process of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com