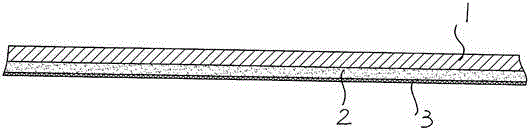

Waterproof roll free of folds and easy to weld

A waterproof membrane and easy-welding technology, which is applied in water conservancy projects, building insulation materials, film/sheet-like adhesives, etc., can solve the problem of laying of difficult-to-waterproof coils, welding construction between sheets, and difficult natural laying Flatness and other problems, to achieve the effect of superior welding effect, good laying compliance, and easy welding construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 68 parts by weight of polyethylene, 18 parts by weight of POE, 11 parts by weight of EVA, 6 parts by weight of polyethylene toughening agent, 5 parts by weight of maleic anhydride compatibilizer and 1 part by weight of polyolefin antiaging agent.

[0015] In addition, the self-adhesive layer constituting the non-crease and easy-to-weld waterproof membrane is non-bitumen self-adhesive, and the isolation film layer is PET polyester film.

[0016] After testing, the tensile strength at break of the coil plate prepared from the above materials is 20MPa, the elongation at break is 810%, the tear strength is 105KN / m, and the welding temperature is 360°C. Paving performance is good.

Embodiment 2

[0018] 70 parts by weight of polyethylene, 16 parts by weight of POE, 10 parts by weight of EVA, 7 parts by weight of polyethylene toughening agent, 6 parts by weight of maleic anhydride compatibilizer and 1.5 parts by weight of polyolefin antiaging agent.

[0019] In addition, the self-adhesive layer constituting the non-crease and easy-to-weld waterproof membrane is non-bitumen self-adhesive, and the isolation film layer is PET polyester film.

[0020] After testing, the tensile strength at break of the coil plate prepared from the above materials is 19.8MPa, the elongation at break is 820%, the tear strength is 110KN / m, the welding temperature is 340°C, and the temperature is 42°C below zero. It paves well.

Embodiment 3

[0022] 65 parts by weight of polyethylene, 15 parts by weight of POE, 9 parts by weight of EVA, 5 parts by weight of polyethylene toughening agent, 4 parts by weight of maleic anhydride compatibilizer and 1.6 parts by weight of polyolefin antiaging agent.

[0023] In addition, the self-adhesive layer constituting the non-crease and easy-to-weld waterproof membrane is non-bitumen self-adhesive, and the isolation film layer is PET polyester film.

[0024] After testing, the tensile strength at break of the coil plate prepared from the above materials is 20.2MPa, the elongation at break is 805%, the tear strength is 102KN / m, the welding temperature is 350°C, and the temperature is 41°C below zero. It paves well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com