High-strength invisible mesh-reinforced wood slag board and production method

An invisible net and high-strength technology, applied in flat products, manufacturing tools, wood processing appliances, etc., can solve the problems of poor toughness, low pressure, and decomposition of wood slag MDF, and achieve good toughness, high bearing pressure, and strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

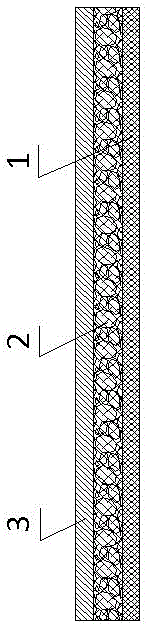

Image

Examples

Embodiment 1

[0009] Embodiment 1: A kind of high-strength invisible mesh reinforcement wood residue board core forming material, its characteristic weight parts are: add 20-25 parts of wood residue powder, add 10-20 parts of glue, add 0.05 parts of wood residue to 100 parts of crushed wood residue blocks -0.15 part of aramid fiber. The material of the broken wood slag block is a mixture of one or more of tree branches, board edges, leftover materials, and waste materials of building templates. The length, width and thickness of the broken wood slag block are controlled within the scope of 3-5cm. The water content of the broken wood residue is below 8%.

Embodiment 2

[0010] Example 2: On the basis of Example 1, 20 parts of wood residue powder, 10 parts of glue, and 0.05 part of aramid fiber were added to 100 parts of crushed wood residue blocks.

Embodiment 3

[0011] Example 3: On the basis of Example 1, 25 parts of wood residue powder, 20 parts of glue, and 0.15 parts of aramid fiber were added to 100 parts of crushed wood residue blocks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com