Organic light emitting diode device and preparation method thereof

An electroluminescent device, organic technology, applied in the direction of electric solid state device, semiconductor/solid state device manufacturing, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

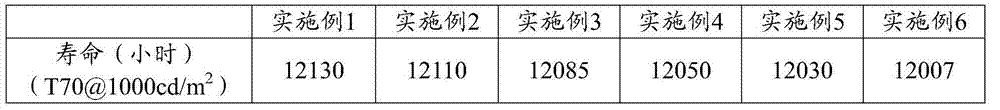

Examples

Embodiment 1

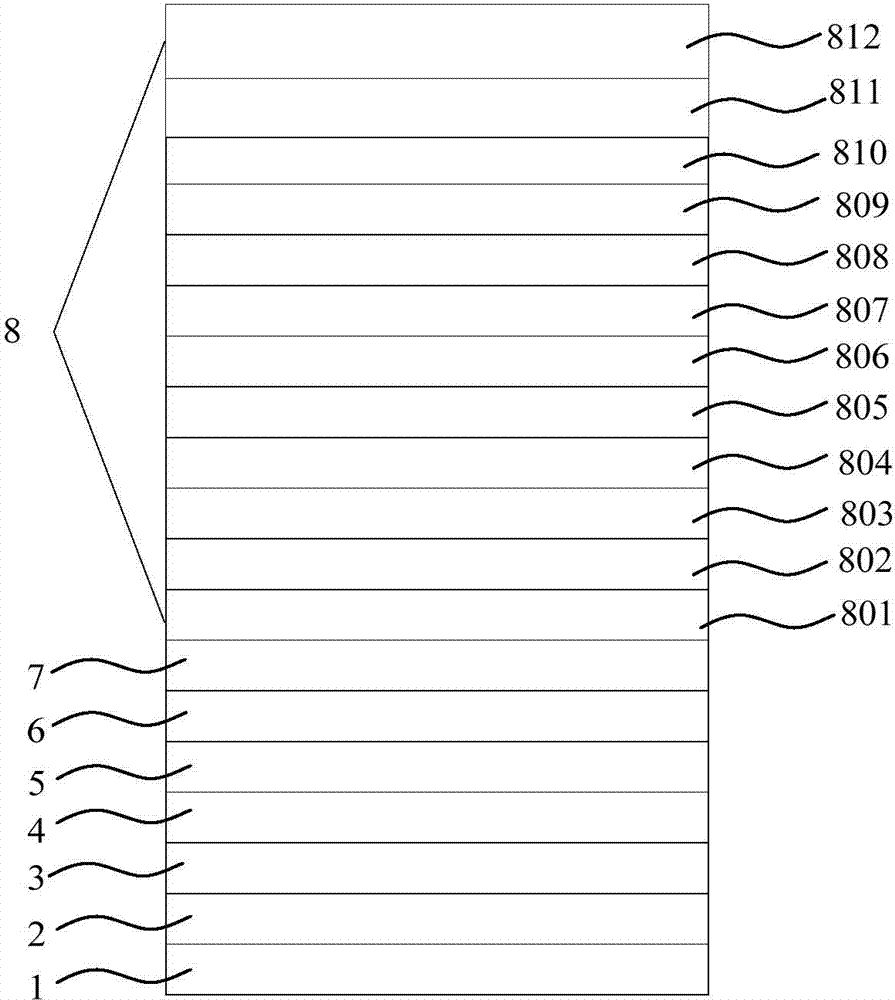

[0062] A method for preparing an organic electroluminescent device, comprising the following steps:

[0063] (1) Pre-treatment of ITO conductive glass substrate 1: put ITO conductive glass substrate 1 into acetone, ethanol, deionized water, and ethanol in sequence, ultrasonically clean them for 5 minutes, then blow dry with nitrogen, and dry them in an oven for later use; The cleaned ITO glass substrate 1 is subjected to surface activation treatment to increase the oxygen content of the conductive surface layer and improve the work function of the conductive layer surface; the thickness of the ITO glass substrate 1 is 100nm;

[0064] Hole injection layer 2: Evaporate MoO on the ITO conductive glass substrate 1 3 Hybrid material obtained by doping NPB, MoO 3 The doping mass fraction in NPB is 30%, and the evaporation is carried out by high-vacuum coating equipment, and the vacuum degree during evaporation is 1×10 -5 Pa, the evaporation rate is A hole injection layer 2 is ob...

Embodiment 2

[0082] A method for preparing an organic electroluminescent device, comprising the following steps:

[0083] Step (1) is the same as embodiment 1;

[0084] (2) Place the organic electroluminescent device sample in a vacuum coating machine, and prepare a mixed barrier layer by vacuum evaporation on the organic electroluminescent device sample. The material of the mixed barrier layer is ZnPc, NPB, CeF 2 and V 2 o 5 Formed hybrid materials, ZnPc, CeF 2 and V 2 o 5 The mole fractions of the mixed materials are 40%, 15% and 10%, respectively, and the evaporation vacuum is 5×10 -5 Pa, the evaporation rate of ZnPc is The thickness of the mixed barrier layer is 150nm;

[0085] (3) The inorganic barrier layer was prepared by atomic layer deposition on the mixed barrier layer, and the material of the inorganic barrier layer was ZrO 2 ;

[0086] A preparation cycle for preparing an inorganic barrier layer is:

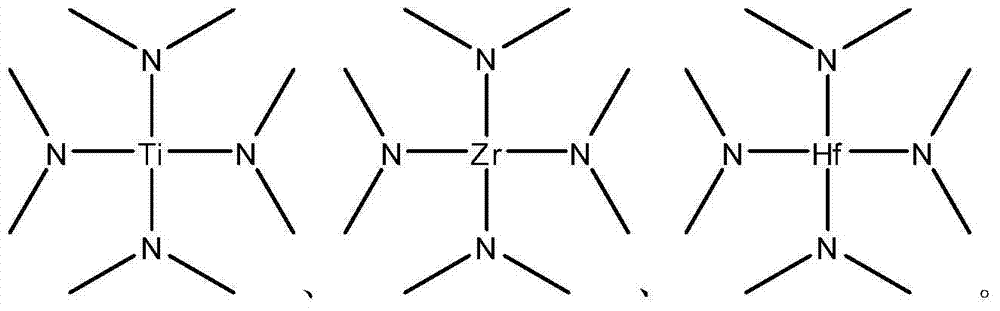

[0087] (a) [Zr(N(CH 3 ) 2 ) 4 ] is injected into the deposition...

Embodiment 3

[0095] A method for preparing an organic electroluminescent device, comprising the following steps:

[0096] Step (1) is the same as embodiment 1;

[0097] (2) Place the organic electroluminescent device sample in a vacuum coating machine, and prepare a mixed barrier layer by vacuum evaporation on the organic electroluminescent device sample. The material of the mixed barrier layer is FePc, Alq3, MgF 2 and WO 3 Formed hybrid materials, FePc, Alq3 and WO 3 The mole fractions of the mixed materials are 60%, 10% and 20% respectively, and the evaporation vacuum is 5×10 -5 Pa, the evaporation rate of FePc is The thickness of the mixed barrier layer is 100nm;

[0098] (3) The inorganic barrier layer was prepared by atomic layer deposition on the mixed barrier layer, and the material of the inorganic barrier layer was HfO 2 ;

[0099] A preparation cycle for preparing an inorganic barrier layer is:

[0100] (a) [Hf(N(CH 3 ) 2 ) 4 ] is injected into the deposition chamber of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com