Rear side grouting device for pile

A technology of grouting device and grouting pipe, which is applied in the direction of construction and basic structure engineering, etc., can solve the problems of increasing the corrosion rate of steel bars, the inability to implement the grouting process, and destroying the integrity of the pile body, so as to improve the pile side resistance, increase Pile-soil contact area, good operability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in combination with two specific embodiments.

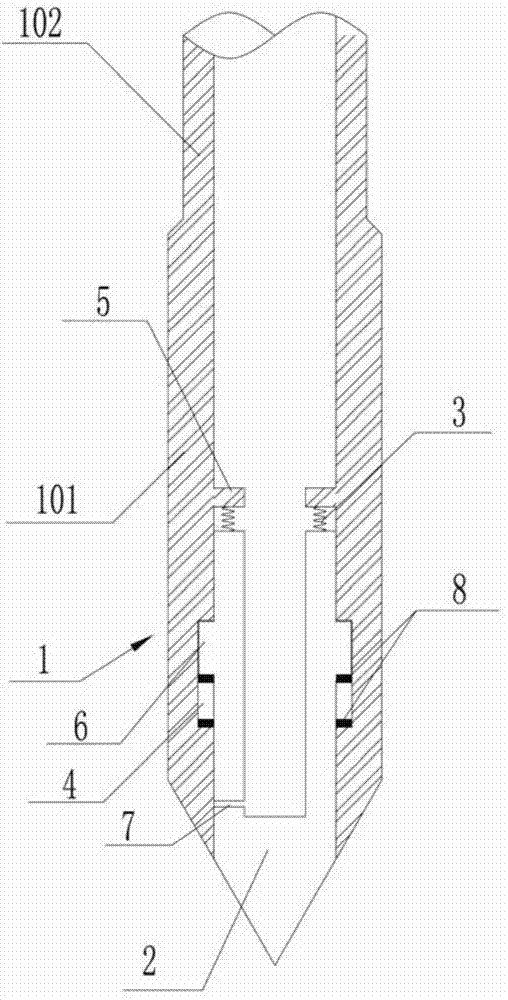

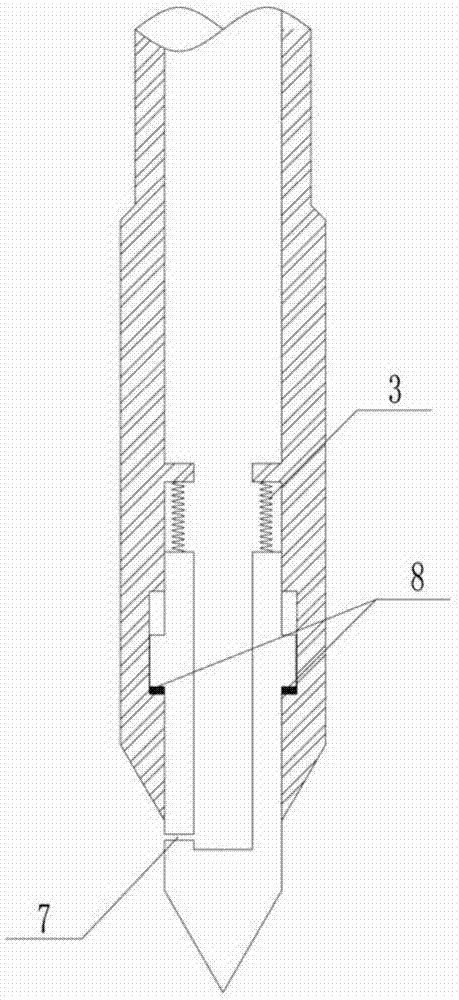

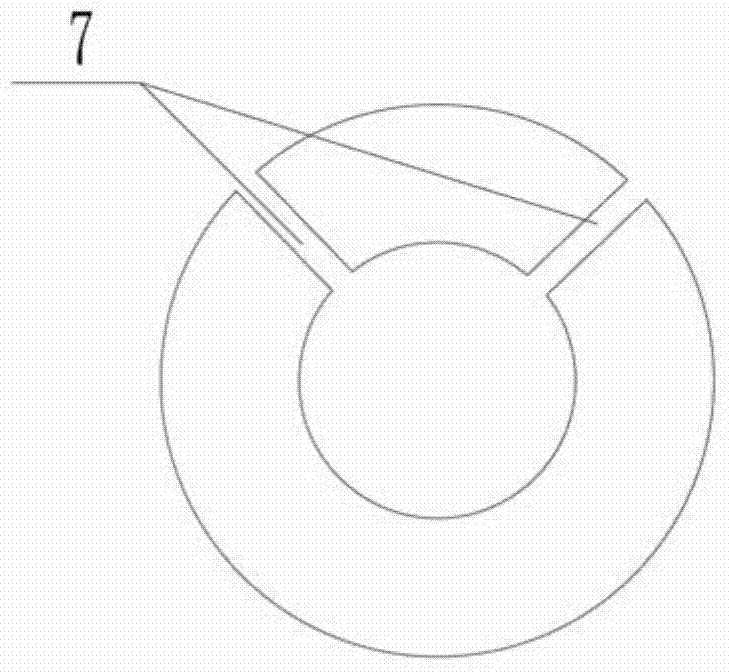

[0035] Such as Figure 1 to Figure 3 As shown, the post-pile grouting device described in this embodiment includes a grouting pipe 1, a grouting head 2 and a spring 3, wherein the outlet end of the grouting pipe 1 is a truncated cone, and its inner cavity The side wall is respectively provided with an annular clamping groove 4 and a retaining ring 5 extending along its circumference, and the annular retaining groove 4 is located between the retaining ring 5 and the outlet of the grouting pipe 1; the head of the grouting head 2 It is a cone, whose taper is consistent with the above-mentioned truncated cone, and can form a conical surface together with the truncated cone, and the cone angle is 60 degrees; the tail of the grouting head 2 extends from the outlet of the grouting pipe 1 into the grouting Inside the pipe 1, grouting holes 7 and snap rings 6 extending along it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com