Electroplating comprehensive wastewater treatment process

A comprehensive electroplating and wastewater treatment technology, which is applied in metallurgical wastewater treatment, special compound water treatment, water/sewage treatment, etc., can solve problems that have not been completely solved, activated carbon life decay, and high pH requirements, and achieve delayed supersaturation time, Extend service life and improve desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

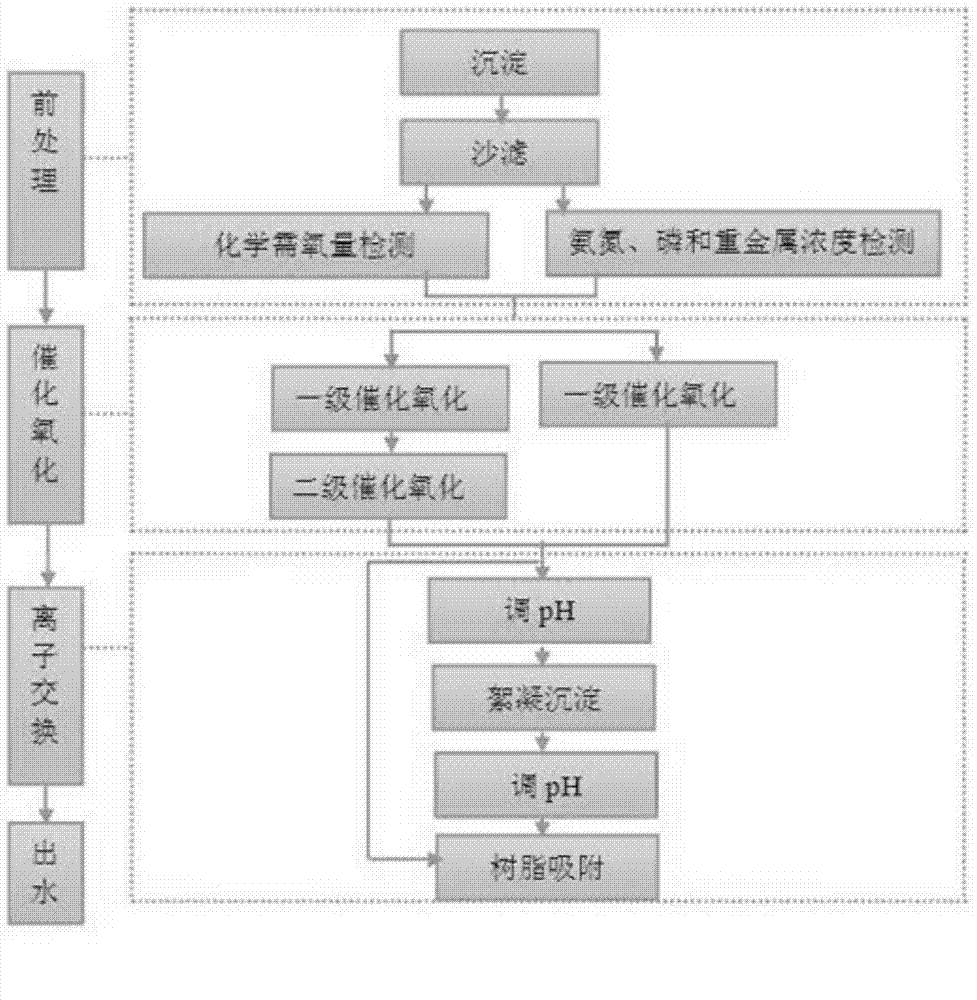

Method used

Image

Examples

Embodiment 1

[0033] This embodiment uses a laboratory to simulate the electroplating comprehensive wastewater of copper oily parts, and the electroplating comprehensive wastewater contains a large amount of organic solvents such as kerosene, gasoline, acetone, and toluene.

[0034] The required raw materials include a specific surface area of 1500~2000m 2 / g of flake activated carbon, ferrous sulfate (FeSO 4 ·7H 2 O), 30% hydrogen peroxide (30% H 2 O 2 ), 4% sulfuric acid (4% H 2 SO 4 );

[0035] The required equipment includes 5B-3B multi-parameter water quality analyzer, AA320N atomic absorption analyzer, catalytic oxidation reactor and copper chelating resin column.

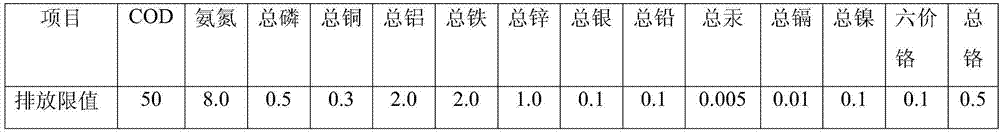

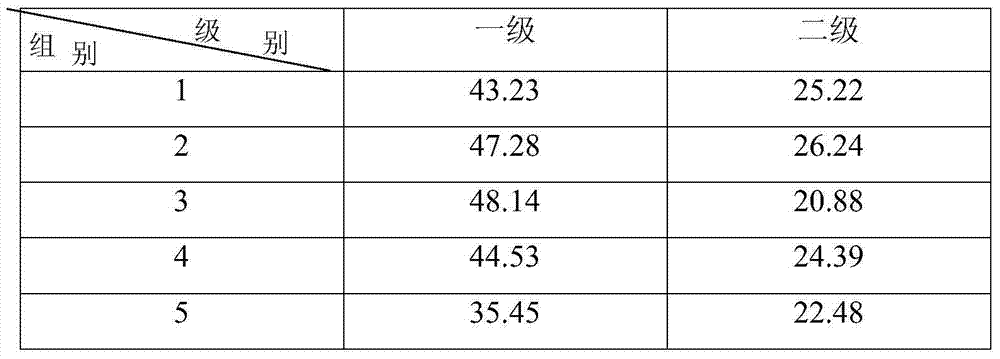

[0036] Step 1. Electroplating comprehensive wastewater pretreatment. First, take the electroplating comprehensive wastewater for precipitation and sand filtration, and conduct an index test on the electroplating comprehensive wastewater. The test items include chemical oxygen demand (COD), total phosphorus, ammonia nitrogen, an...

Embodiment 2

[0052] In this embodiment, the raffinate from Ganzhou 801 Plant is used as the electroplating comprehensive wastewater to be treated.

[0053] The required raw materials include a specific surface area of 1500~2000m 2 / g of flake activated carbon, ferrous sulfate (FeSO 4 ·7H 2 O), 30% hydrogen peroxide (30% H 2 O 2 ), 4% sulfuric acid (4% H 2 SO 4 ), flocculant;

[0054] The required equipment includes 5B-3B multi-parameter water quality analyzer, AA320N atomic absorption analyzer, catalytic oxidation reactor and de-nickel chelating resin column.

[0055] Step 1. Electroplating comprehensive wastewater pretreatment. First, take the raffinate from the Ganzhou 801 plant for precipitation and sand filtration, and conduct index tests on the electroplating integrated wastewater. The test items include chemical oxygen demand (COD), total phosphorus, ammonia nitrogen, and heavy metal ions. Among them, chemical oxygen demand (COD), total phosphorus and ammonia nitrogen are detected by 5B-...

Embodiment 3

[0071] In this embodiment, the wastewater from the Gang'an electroplating plant is used as the comprehensive electroplating wastewater to be treated.

[0072] The required raw materials include a specific surface area of 1500~2000m 2 / g of flake activated carbon, ferrous sulfate (FeSO 4 ·7H 2 O), 30% hydrogen peroxide (30% H 2 O 2 ), 4% sulfuric acid (4% H 2 SO 4 ), quicklime, flocculant;

[0073] The required equipment includes 5B-3B multi-parameter water quality analyzer, AA320N atomic absorption analyzer, catalytic oxidation reactor, pH meter, hexavalent chromium removal, acid removal, copper removal, nickel removal, phosphorus removal and ammonia nitrogen chelating resin column.

[0074] Step 1. Electroplating comprehensive wastewater pretreatment. Take the wastewater from the Gang'an electroplating plant as the comprehensive electroplating wastewater to be treated, and carry out precipitation and sand filtration to test the indicators of the electroplating comprehensive waste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com