Lithium ion battery graphene conductive agent and preparation method thereof

A lithium-ion battery and graphene technology, applied in the field of lithium-ion batteries, can solve the problems of reduced electrode capacity and high cost of carbon nanotubes, and achieve the effects of increasing capacity, saving costs, and strong liquid absorption and retention capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

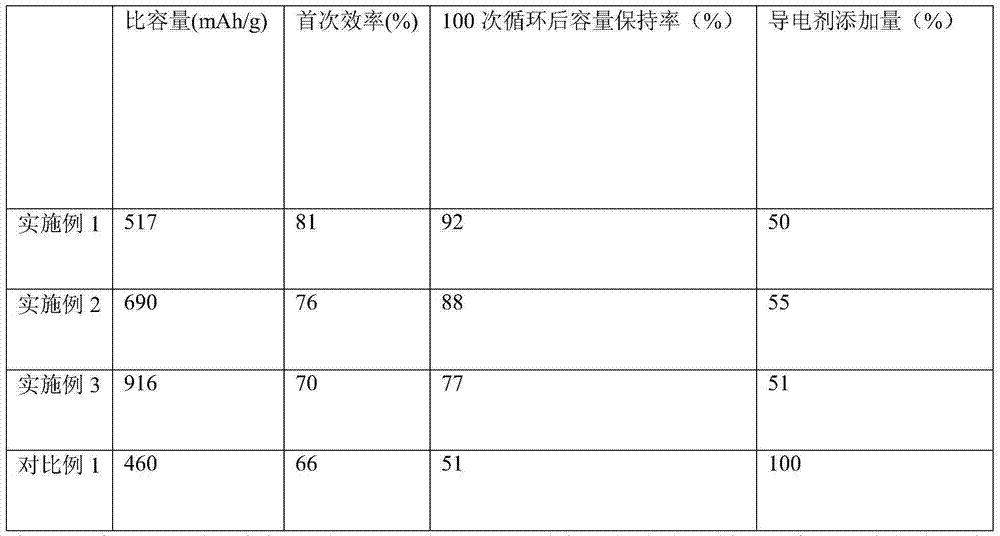

Examples

Embodiment 1

[0029] A kind of preparation method of lithium ion battery graphene conductive agent, described preparation method comprises the following steps:

[0030] 1) Mix 25g of graphene, 5g of monoethanolamine and 50g of water, and ultrasonically disperse for 10min to obtain premix A; the ultrasonic frequency is 50KHz;

[0031] 2) Mix 10g of polyethylene glycol, 1g of rare earth gadolinium and 50g of water, and stir at 30°C for 30min to obtain premix B;

[0032] 3) Mix the premix A obtained in step 1) with the premix B obtained in step 2) and add 0.5 g of titanium carbide. While adding titanium carbide, apply a magnetic field with a strength of 3000 GS. After the titanium carbide is completely added, turn the magnetic field Increase the strength to 5000GS, stir for 15 minutes, and then disperse ultrasonically for 30 minutes under ultrasonic conditions; the ultrasonic frequency is 50KHz to obtain a graphene conductive agent for lithium-ion batteries.

Embodiment 2

[0034] A kind of preparation method of lithium ion battery graphene conductive agent, described preparation method comprises the following steps:

[0035] 51) Mix 28g of graphene, 8g of monoethanolamine and 70g of ethanol, and ultrasonically disperse for 12min to obtain premix A; the ultrasonic frequency is 55KHz;

[0036] 2) Mix 12g of polyethylene glycol, 3g of rare earth element terbium and 70g of ethanol, and stir at 35°C for 45min to obtain premix B;

[0037] 3) Mix the premix A obtained in step 1) with the premix B obtained in step 2) and add 0.85 g of titanium carbide. While adding titanium carbide, apply a magnetic field with a strength of 4000 GS. After the titanium carbide is completely added, turn the magnetic field The intensity was increased to 5200GS, and stirred for 18 minutes, and then ultrasonically dispersed for 40 minutes under ultrasonic conditions; the ultrasonic frequency was 55KHz, and a graphene conductive agent for lithium-ion batteries was obtained. ...

Embodiment 3

[0039] A kind of preparation method of lithium ion battery graphene conductive agent, described preparation method comprises the following steps:

[0040] 1) Mix 30g of graphene, 10g of monoethanolamine and 80g of acetone, and ultrasonically disperse for 25 minutes to obtain premix A; the ultrasonic frequency is 65KHz;

[0041] 2) Mix 15g of polyethylene glycol, 5g of rare earth element terbium and 80g of acetone, and stir at 45°C for 60min to obtain premix B;

[0042] 3) Mix the premix A obtained in step 1) with the premix B obtained in step 2) and add 1g of titanium carbide. While adding titanium carbide, apply a magnetic field with a strength of 4500GS. After the titanium carbide is completely added, turn the magnetic field Increase the strength to 5500GS, stir for 20 minutes, and then disperse ultrasonically for 45 minutes under ultrasonic conditions; the ultrasonic frequency is 65KHz to obtain a graphene conductive agent for lithium-ion batteries.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com