Preparation method of corrosion inhibitor for novel ionic liquid oil field water

A technology of ionic liquids and corrosion inhibitors, which is applied in the field of synthetic oilfield water injection compound corrosion inhibitors, can solve the problems of rapid corrosion of oilfield reinjection water pipelines, and achieve the effects of increasing activation energy, reducing corrosion speed, and slowing down corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

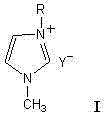

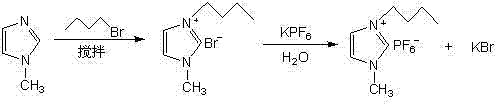

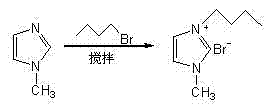

[0036] Example 1: Synthesis of [Bmim]Br

[0037] Weigh 32ml of N-methylimidazole solution and 44ml of n-bromobutane solution and add them into a three-neck flask equipped with a reflux condenser. A calcium chloride drying tube is installed on the reflux condenser. Heat and stir the mixture at 70°C. It was reacted for 24h, cooled to room temperature, and the crude product was obtained. Then put the crude product into a separatory funnel, wash with about 30mL of ethyl acetate each time, wash twice in total, remove the ethyl acetate by rotary evaporation, dry in vacuum at 60°C for 24h, and keep the weight constant to obtain a light yellow viscous The liquid [Bmim]Br was 76.53g, and the yield was 85.11%. The reaction equation is as follows:

[0038]

[0039] To simulate the composition of oilfield reinjection water quality, add 0.0003623molNaSO to 1L of water 4 , 0.00815molK 2 SO 4 , 0.01923molCaCl 2 , 0.01143molMgCl 2 , 0.001655molMgSO 4 , 0.0035gNa 2 S, 0.0000417mol ...

example 2

[0041] Measure 8 mL of N-methylimidazole and 12 mL of benzyl chloride into a three-necked flask equipped with a reflux condenser, heat and stir the mixture at 70 °C to react for 20 h, cool to room temperature, and separate layers to obtain a crude product. Then put the crude product into a separatory funnel, wash it twice with about 60 mL of ethyl acetate, and remove the ethyl acetate by rotary evaporation to obtain a brown viscous liquid a. Weigh 16.00 g of compound a and 16.50 g of NaBF 4 The mixture was added to a three-necked flask equipped with a reflux condenser, 100 mL of water was added as a solvent, the mixture was heated and stirred at 70 °C to react for 20 h, and the water was removed by rotary evaporation after the reaction. Dry in vacuum at 60°C for 24h to obtain a light brown liquid. The reaction equation is as follows:

[0042]

[0043] To simulate the composition of oilfield reinjection water quality, add 0.0003623molNaSO to 1L of water 4 , 0.00815molK 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com