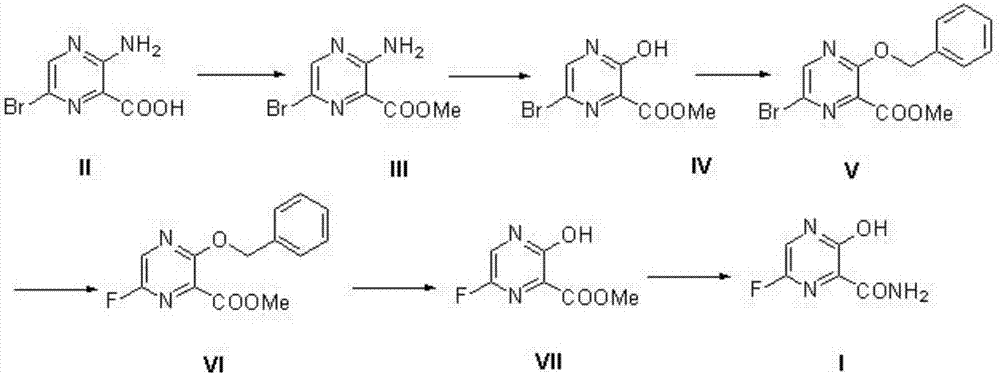

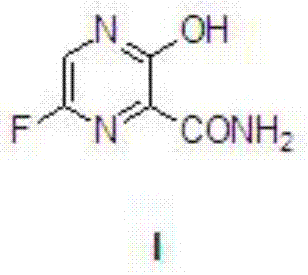

A kind of synthetic method of favipiravir

A technology of favipiravir and synthetic route, applied in the direction of organic chemistry and the like, can solve problems such as being unfavorable to industrialized production, and achieve the effects of low production cost, short reaction period and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

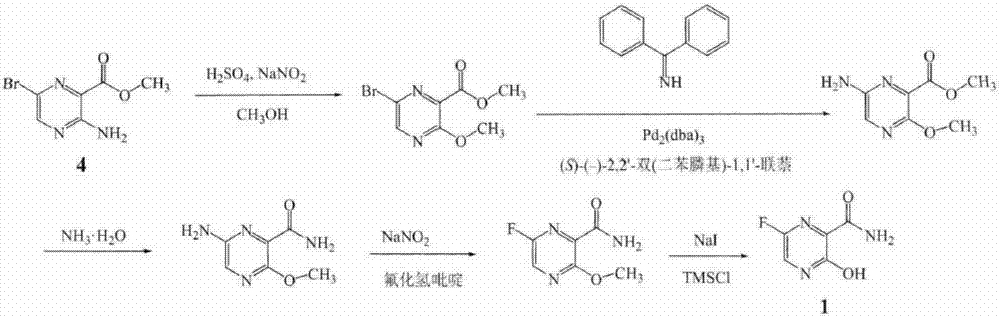

Method used

Image

Examples

Embodiment 1

[0041] The preparation of embodiment 1 compound III

[0042] molecular weight Feeding amount Moles / mmol equivalent Ⅱ 218.01 50.1g 230 1 98.3% concentrated sulfuric acid 98.08 133g 1380 6 Methanol 2.2L sodium bicarbonate 84.01 231.9g 2760 12

[0043] Add 50.1g II and 2L methanol to the 3L reaction flask. At 0-5°C, slowly add 133g of 98.3% concentrated sulfuric acid dropwise thereto, after the drop is complete, raise the temperature to 40°C, and react for about 48 hours until the reaction of raw material II is basically completed.

[0044] Spin-dry methanol, add 200mL methanol and 500g ice-water mixture to it at 0-5°C, and add saturated aqueous sodium bicarbonate solution dropwise thereto to adjust the pH to 6-7. After suction filtration, the filter cake was vacuum-dried at 45° C. for 12 hours to obtain 43.2 g of brown solid III, with a yield of 80.1%.

[0045] MS(m / z):233[M+H] + ; 1 H NMR (DMSO-d 6 )δ: 3.95(s,3H), ...

Embodiment 2

[0046] The preparation of embodiment 2 compound IV

[0047] molecular weight Feeding amount Moles / mmol equivalent Ⅲ 232.03 43g 185.3 1 98.3% concentrated sulfuric acid 98.08 43mL sodium nitrite 69.0 25.6g 371 2

[0048] Add 43g III and 43mL 98.3% concentrated sulfuric acid into a 250mL reaction flask, and stir. At -10~-5°C, add 25.6g of sodium nitrite to it, raise the temperature to 20~25°C after adding, keep stirring for about 0.5h until the reaction of the raw materials is basically completed.

[0049] Slowly add the reaction solution dropwise into 430g of ice water, and keep stirring for about 1.5h until the reaction is complete. After suction filtration, the filter cake was air-dried at 50° C. for 6 hours to obtain 36.7 g of orange solid IV with a yield of 85%.

[0050] MS(m / z):232[M-H] - ; 1 H NMR (DMSO-d 6 )δ: 3.95(s,3H), 8.21(s,1H), 11.52(s,1H).

Embodiment 3

[0051] The preparation of embodiment 3 compound IV

[0052] molecular weight Feeding amount Moles / mmol equivalent Ⅲ 232.03 43g 185.3 1 98.3% concentrated sulfuric acid 98.08 21.5mL 0.5 sodium nitrite 69.0 12.8g 371 1

[0053] Add 43g III and 43mL 98.3% concentrated sulfuric acid into a 250mL reaction flask, and stir. At -20-0°C, add 25.6g of sodium nitrite to it, raise the temperature to 55-60°C after the addition, keep stirring for about 30 minutes until the raw materials are basically reacted.

[0054] Slowly add the reaction solution dropwise into 430g of ice water, and keep stirring for about 1.5h until the reaction is complete. After suction filtration, the filter cake was air-dried at 50° C. for 6 hours to obtain 37.6 g of orange solid IV with a yield of 87%.

[0055] MS(m / z):232[M-H] - ;1 H NMR (DMSO-d 6 )δ: 3.95(s,3H), 8.21(s,1H), 11.52(s,1H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com