Low-temperature seal glass material and preparation method of composite filler

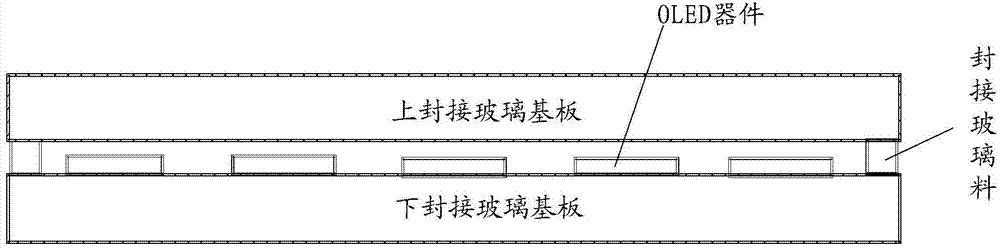

一种复合填料、封接玻璃的技术,应用在玻璃生产领域,能够解决微裂纹、不利整体封接材料强度、不利OLED器件封装良率等问题,达到提高封装良率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

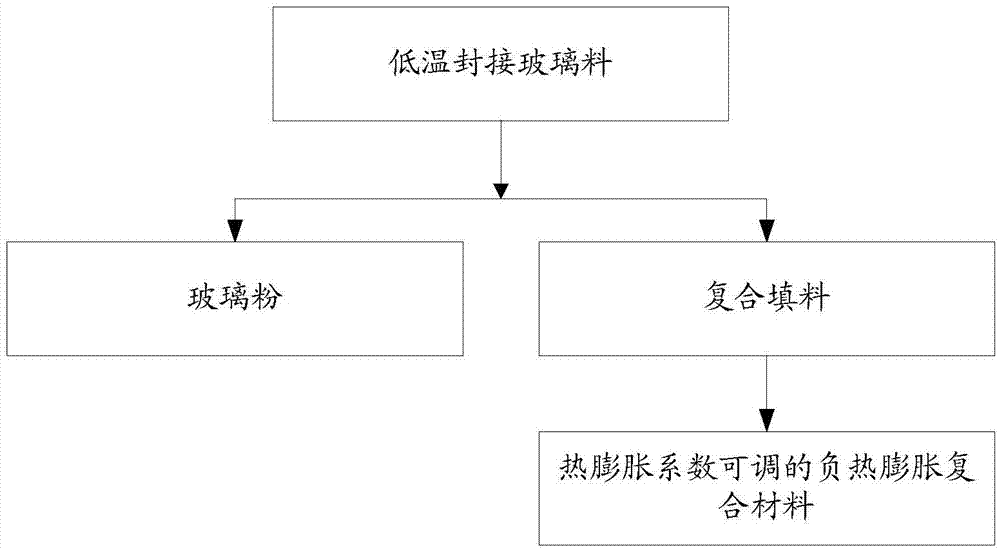

[0028] Such as figure 2 The low-temperature sealing glass frit provided by the illustrated embodiment of the present invention includes glass frit and fillers, and the fillers at least include composite fillers. Among them, the composite filler is a negative thermal expansion composite material whose thermal expansion coefficient can be adjusted. The common glass powder is made of V2O5, TeO2, Fe2O3, Co2O3, TiO2, ZrO2, ZnO, K 2 O one or more components.

[0029] The composite filler in this example is a composite material obtained by chemical reaction of a mixture of zirconium tungstate and silicon dioxide at high temperature. Among them, zirconium tungstate is an isotropic negative thermal expansion material, and silicon dioxide is an amorphous silicon dioxide powder, which is a zero thermal expansion material. Isotropic negative thermal expansion materials will shrink in the three crystal axis directions when heated, and the shrinkage coefficient is the same, with cubic sy...

Embodiment 2

[0049] By expanding the components of the composite fillers in the above embodiments, other negative thermal expansion composite fillers with adjustable thermal expansion coefficients and low-temperature sealing glass frits with adjustable thermal expansion coefficients can be obtained. Among them, the composite filler can at least be expanded as follows according to the components:

[0050] Supplementary Example 1: The composite filler is a composite material obtained by chemically reacting a mixture of zirconium tungstate, silicon dioxide and cordierite at high temperature. The complex phase of the composite filler includes zirconium tungstate-silicon dioxide complex phase and zirconium tungstate-cordierite complex phase.

[0051] Supplementary Example 2: The composite filler is a composite material obtained by chemically reacting a mixture of zirconium tungstate, silicon dioxide and eucryptite at high temperature. The complex phase of the composite filler includes zirconiu...

Embodiment 3

[0052] Supplementary Example 3: The composite filler is a composite material obtained by chemical reaction of a mixture of zirconium tungstate, silicon dioxide, cordierite and eucryptite at high temperature. The complex phase of the composite filler includes zirconium tungstate-silicon dioxide complex phase, zirconium tungstate-cordierite complex phase and zirconium tungstate-eucryptite complex phase.

[0053] Among them, zirconium tungstate is an isotropic negative thermal expansion material, silicon dioxide is a zero thermal expansion material, and eucryptite and cordierite are anisotropic negative thermal expansion materials.

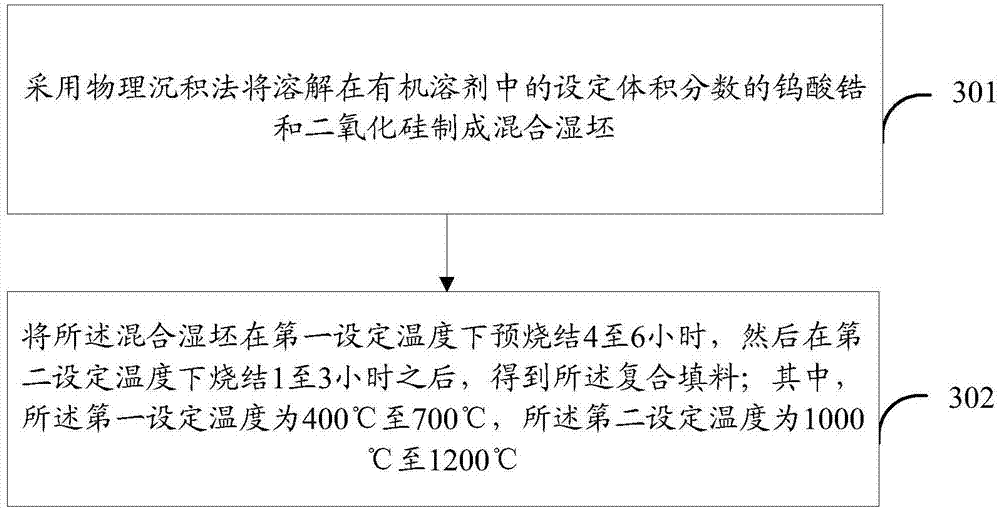

[0054] Take the composite filler of Supplementary Example 1 as an example, such as Figure 5 The specific steps for preparing the composite filler shown are:

[0055] Step 501: making a mixed wet compact from zirconium tungstate, silicon dioxide, and cordierite dissolved in an organic solvent with a set volume fraction by physical deposition;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of thermal expansion | aaaaa | aaaaa |

| coefficient of thermal expansion | aaaaa | aaaaa |

| coefficient of thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com