Method for preparing high alpha-phase silicon nitride by utilizing porous silicon

A technology of phase silicon nitride and porous silicon, which is applied in the field of preparing high-alpha phase silicon nitride by using porous silicon, can solve the problems that the degree of nitriding is difficult to control, it is not suitable for industrial production, and the operation process is complicated, so as to achieve short production cycle , Inhibit self-sintering, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation process of porous silicon raw material is as follows:

[0030] Place magnesium silicide in a high-temperature heat treatment furnace for heat treatment, the reaction temperature is 450°C, and the time is 35 hours. During the whole heat treatment process, a mixed gas of argon and oxygen is introduced, and the content of oxygen is 25%.

[0031] The product obtained above was washed three times with 1Mol / L hydrochloric acid and deionized water respectively, then centrifuged, and then dried under vacuum.

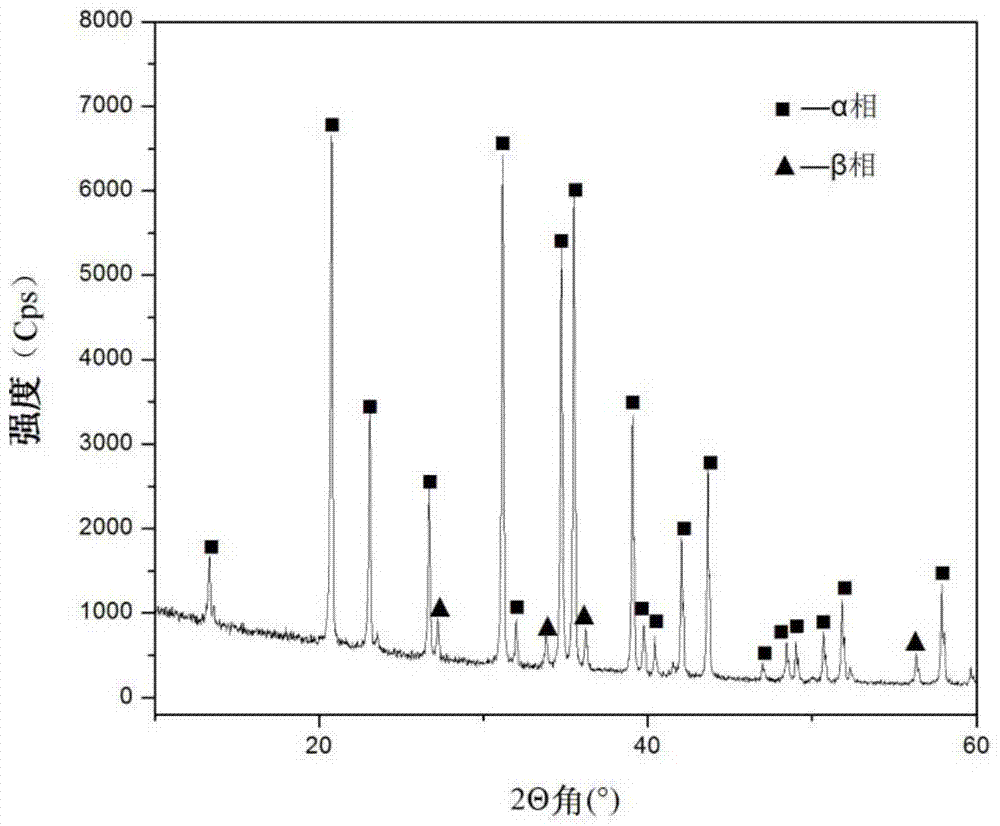

[0032] The above-mentioned self-prepared porous silicon raw material is used, the particle size is 1-5 μm, and the specific surface area is greater than 100m 2 / g, the pore size of porous silicon is 75-150nm. Under a nitrogen atmosphere, keep warm at 1300°C for 25 hours to obtain loose high-α-phase silicon nitride. The obtained silicon nitride is then ball-milled using a planetary ball mill. The grinding ball is hot-pressed and sintered silicon nitride ...

Embodiment 2

[0035] The preparation process of porous silicon raw material is as follows:

[0036] Place magnesium silicide in a high-temperature heat treatment furnace for heat treatment, the reaction temperature is 500°C, and the time is 30 hours. During the whole heat treatment process, a mixed gas of argon and oxygen is introduced, and the content of oxygen is 15%.

[0037] The product obtained above was washed three times with 1Mol / L hydrochloric acid and deionized water respectively, then centrifuged, and then dried under vacuum.

[0038] The above-mentioned self-prepared porous silicon raw material is used, the particle size is 7.5-10 μm, and the specific surface area is greater than 100m 2 / g, the porous silicon pore size is 100-200nm. Under a nitrogen atmosphere, keep warm at 1320°C for 20 hours to obtain loose high-α-phase silicon nitride. The obtained silicon nitride is then ball-milled using a planetary ball mill. The grinding ball is hot-pressed and sintered silicon nitride ...

Embodiment 3

[0041] The preparation process of porous silicon raw material is as follows:

[0042] The magnesium silicide is placed in a high-temperature heat treatment furnace for heat treatment, the reaction temperature is 600°C, and the time is 20 hours. During the whole heat treatment process, a mixed gas of argon and oxygen is introduced, and the content of oxygen is 10%.

[0043] The product obtained above was washed three times with 1Mol / L hydrochloric acid and deionized water respectively, then centrifuged, and then dried under vacuum.

[0044] The above-mentioned self-prepared porous silicon raw material is used, the particle size is 10-20 μm, and the specific surface area is greater than 100m 2 / g, the pore size of porous silicon is 150-500nm. Under a nitrogen atmosphere, keep warm at 1350°C for 15 hours to obtain loose high-α-phase silicon nitride. The obtained silicon nitride is then ball-milled using a planetary ball mill. The grinding ball is hot-pressed and sintered silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com