High-partial-discharge-voltage photovoltaic backplane

A photovoltaic backplane, high partial discharge technology, applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

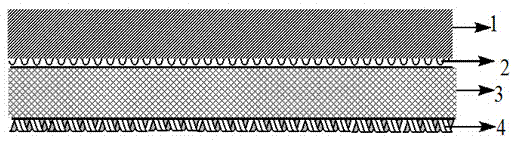

Method used

Image

Examples

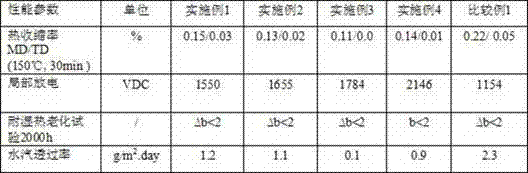

Embodiment 1

[0105]In the manufacturing process of the backboard, firstly, polyethylene terephthalate (U.S. DuPont Company) 85wt%, inorganic filler titanium dioxide R902 (U.S. DuPont Company) 10wt%, hydrolysis stabilizer monomer carbodiimide I powder ( Rheinland Chemical) 2wt%, anti-thermal and oxidative aging agent bisphenol A bis(diphenyl phosphate) (Gansu Provincial Research Institute of Chemical Industry) 1wt%, after mixing evenly, melt processing at 250-260°C and cast into a film A 250 micron thick polyester substrate film was obtained.

[0106] Then, a 5 micron thick weather resistant tie coat was rolled on one side of the polyester base layer. The adhesive layer coating ingredients are acrylic resin 7105# (DSM) 75wt%, inorganic filler titanium dioxide R960 (DuPont, USA) 15wt%, UV absorber 2,4-bis(2-hydroxy-4-alkoxy ) phenyl-6-(4-biphenyl)-1,3,5-triazine (Medical Chemical Manufacturing Co., Ltd.) 0.1wt%, light stabilizer bis-1-decyloxy-2,2 , 6,6-tetramethylpiperidin-4-ol sebacate (...

Embodiment 2

[0110] In the manufacturing process of the backsheet, 87wt% polybutylene terephthalate (DuPont, USA), 8wt% inorganic filler titanium dioxide (DuPont, USA), 8wt% polybutylene terephthalate (DuPont, USA), 8wt% hydrolysis stabilizer monomer carbodiimide P200 (Germany Rhine Chemicals) 4wt%, anti-thermal and oxidative aging agent tris(1,2,2,6-pentamethyl-4-4-piperidinyl) phosphite (Gansu Provincial Research Institute of Chemical Industry) 1wt%, after mixing evenly Melt processing at 250-260°C and casting into a film to prepare a 200 micron thick polyester base layer film.

[0111] Then, a 10-micron thick weather-resistant tie coat was rolled on one side of the polyester base layer. The adhesive layer coating ingredients are 90wt% of fluororesin DM-301 (Jiangsu Kelong Company), 9.4wt% of curing agent isophorone diisocyanate trimer (German Bayer Company), 9.4wt% of catalyst dioctyltin dilaurate (Shanghai Xindian Chemical Co., Ltd.) Materials Limited) 0.6wt%. Prepared by mixing raw ...

Embodiment 3

[0115] In the manufacturing process of the backsheet, 90wt% of polyethylene naphthalate (Changchun, Taiwan), 5wt% of inorganic filler titanium dioxide R902 (DuPont, USA), and polycarbodiimide P400 (Germany Rheinland Chemical Co., Ltd.) ) 3wt%, thermal oxygen aging agent 1,3,5-tris(4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl)-1,3,5-triazine-2, 4,6-(1H,3H,5H)-triketone (Gansu Provincial Institute of Chemical Industry) 2 wt%, mixed evenly, melted and processed at 250-260°C and cast into a film to obtain a 300 micron thick polyester matrix layer film.

[0116] Then, one side of the polyester base layer was sprayed with a 20 micron thick weather resistant tie coat. The adhesive layer coating ingredients are GK5790 alkyd resin (Toyobo Co., Ltd., Japan) 80wt%, inorganic filler aluminum hydroxide (Hefei Zhongke Co., Ltd.) 10.2wt%, curing agent isophorone diisocyanate prepolymer (Bayer Co., Ltd., Germany) 8.8wt%, catalyst zinc naphthenate (Shanghai Xindian Chemical Materials Co., Ltd.)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com