Bismuth phosphate nano crystal cluster as well as preparation method and application thereof

A bismuth phosphate nanometer and crystal cluster technology, applied in the field of material science, can solve the problems of not commonly used chemical reagents, reduced pressure and high temperature environment, short reaction time, etc., and achieve the effect of simple and easy control, mild reaction conditions and fast reaction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

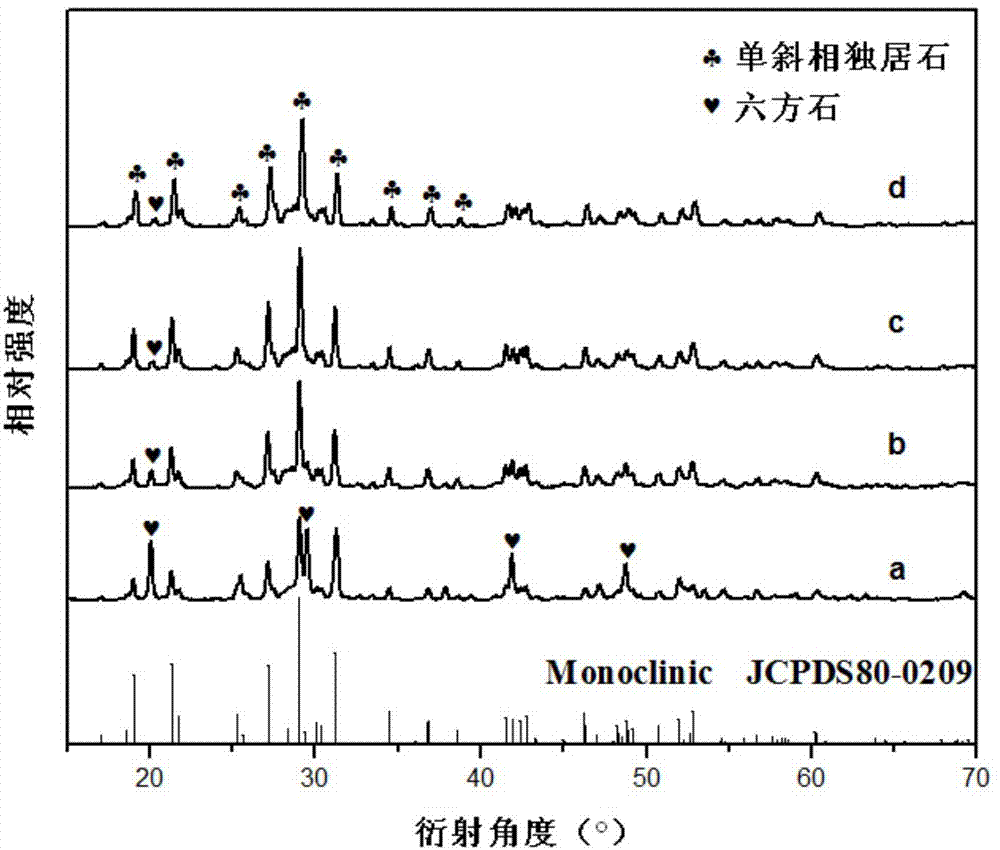

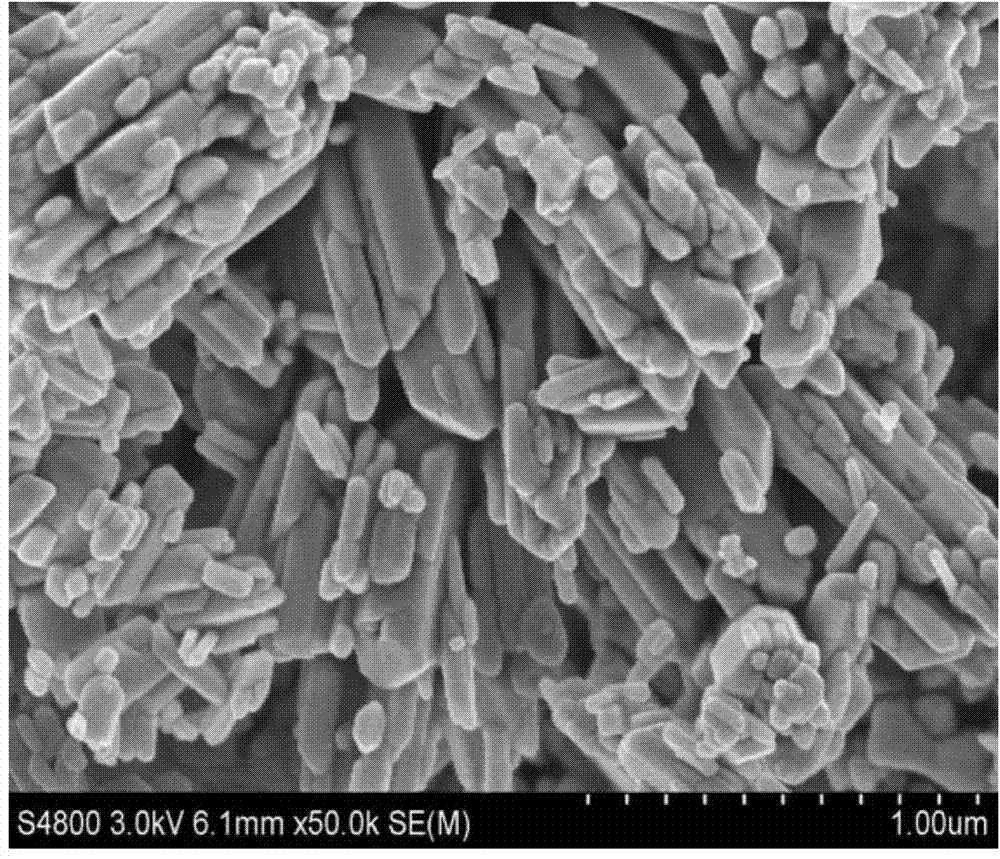

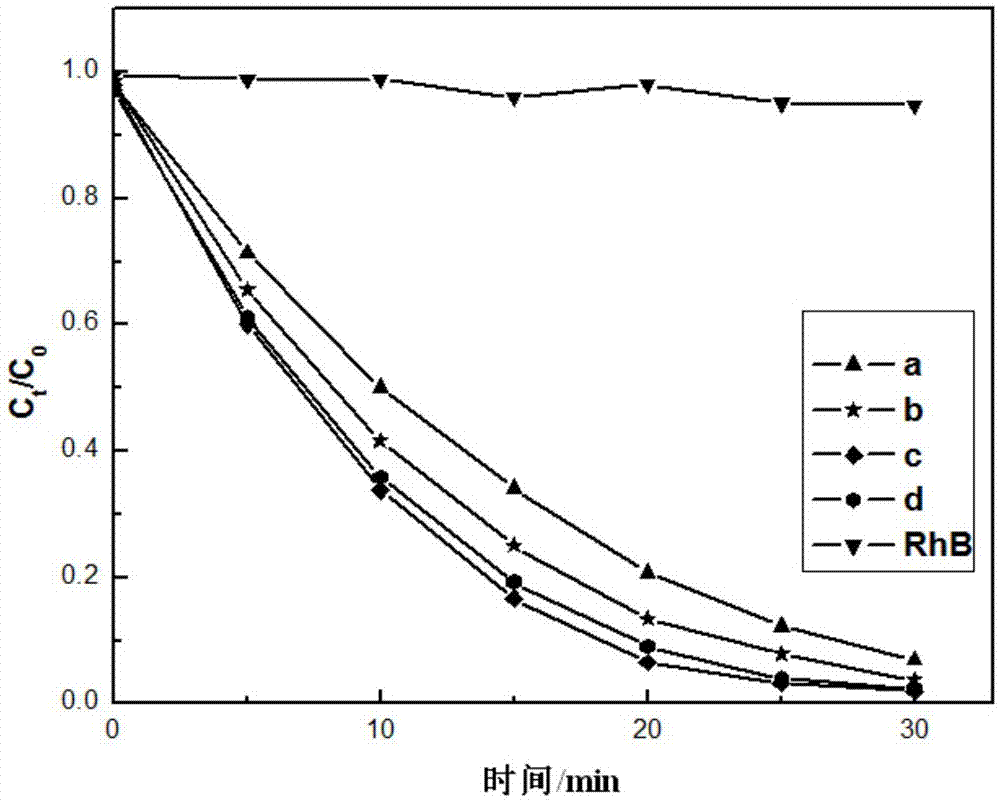

Embodiment 1

[0029] Step 1: Add 0.003mol Bi(NO 3 ) 3 ·5H 2 O and 0.003mol Na 3 PO 4 12H 2 O was dissolved in 50ml deionized water and mixed evenly to obtain a precursor solution; in the precursor solution Bi(NO 3 ) 3 ·5H 2 O and Na 3 PO 4 12H 2 The concentration of O is 0.06mol / L;

[0030] Step 2: Put the precursor liquid into the microwave hydrothermal reaction kettle lined with polytetrafluoroethylene, control the filling ratio of the microwave hydrothermal reaction kettle to 50%, seal the microwave hydrothermal reaction kettle; put the microwave hydrothermal reaction kettle Put it into the microwave hydrothermal reaction instrument, select the microwave digestion (temperature control) scheme, set the microwave power to 300W, raise the temperature from room temperature to 100°C, and keep it at 100°C for 8 minutes; then raise the temperature from 100°C to 150°C, Keep warm for 8 minutes; then raise the temperature from 150°C to 160°C, and stop the reaction after holding at 160°C...

Embodiment 2

[0033] Step 1: Add 0.003mol Bi(NO 3 ) 3 ·5H 2 O and 0.003mol Na 3 PO 4 12H 2 O was dissolved in 50ml deionized water and mixed evenly to obtain a precursor solution; in the precursor solution Bi(NO 3 ) 3 ·5H 2 O and Na 3 PO 4 12H 2 The concentration of O is 0.06mol / L;

[0034]Step 2: Put the precursor liquid into the microwave hydrothermal reaction kettle lined with polytetrafluoroethylene, control the filling ratio of the microwave hydrothermal reaction kettle to 50%, seal the microwave hydrothermal reaction kettle; put the microwave hydrothermal reaction kettle Put it into the microwave hydrothermal reaction instrument, select the microwave digestion (temperature control) scheme, set the microwave power to 300W, raise the temperature from room temperature to 100°C, and keep it at 100°C for 8 minutes; then raise the temperature from 100°C to 150°C, Keep warm for 8 minutes; then raise the temperature from 150°C to 180°C, and stop the reaction after holding at 180°C ...

Embodiment 3

[0037] Step 1: Add 0.003mol Bi(NO 3 ) 3 ·5H 2 O and 0.003mol Na 3 PO 4 12H 2 O was dissolved in 50ml deionized water and mixed evenly to obtain a precursor solution; in the precursor solution Bi(NO 3 ) 3 ·5H 2 O and Na 3 PO 4 12H 2 The concentration of O is 0.06mol / L;

[0038] Step 2: Put the precursor liquid into the microwave hydrothermal reaction kettle lined with polytetrafluoroethylene, control the filling ratio of the microwave hydrothermal reaction kettle to 50%, seal the microwave hydrothermal reaction kettle; put the microwave hydrothermal reaction kettle Put it into the microwave hydrothermal reaction instrument, select the microwave digestion (temperature control) scheme, set the microwave power to 300W, raise the temperature from room temperature to 100°C, and keep it at 100°C for 8 minutes; then raise the temperature from 100°C to 150°C, Keep warm for 8 minutes; then raise the temperature from 150°C to 200°C, and stop the reaction after holding at 200°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com