Optical microwave waste gas purifier

A waste gas purifier and purifier technology, applied in the direction of chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of increasing atmospheric precipitation, plant leaf damage, plant yield decline, etc., to achieve low operating costs, The effect of short process flow and low investment intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

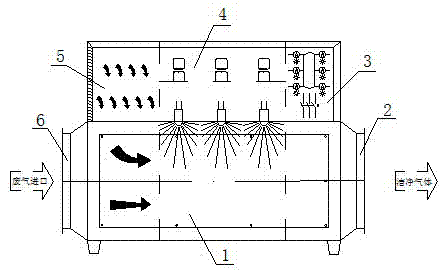

[0011] Such as figure 1 An optical microwave exhaust gas purifier shown includes a purifier body 1. The left end of the purifier body 1 is an exhaust gas inlet 6 and the right end is a clean gas outlet 2. The upper right end of the purifier body 1 is provided with a control system panel 3 The middle of the purifier body 1 is provided with a microwave emission system 4; the upper left end of the purifier body 1 is provided with an air chamber 5 for introducing air into the purifier body 1; the air chamber 5 An air filter is connected to it; an exhaust gas filter is arranged in the purifier body 1.

[0012] The main principle of optical microwave processing is that an electromagnetic wave is generated by microwave, and the heating property of electromagnetic wave is used. As an electromagnetic wave, it also has wave-particle duality. Its interaction with biological tissues is mainly manifested in thermal and non-thermal effects.

[0013] Electromagnetic waves can be transmitted in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com